Assembly system for synchronizing devices in a gearbox

A synchronizing device and gearbox technology, applied in rigid shaft couplings, clutches, mechanical drive clutches, etc., can solve problems such as increasing the axial thickness of the synchronizing mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

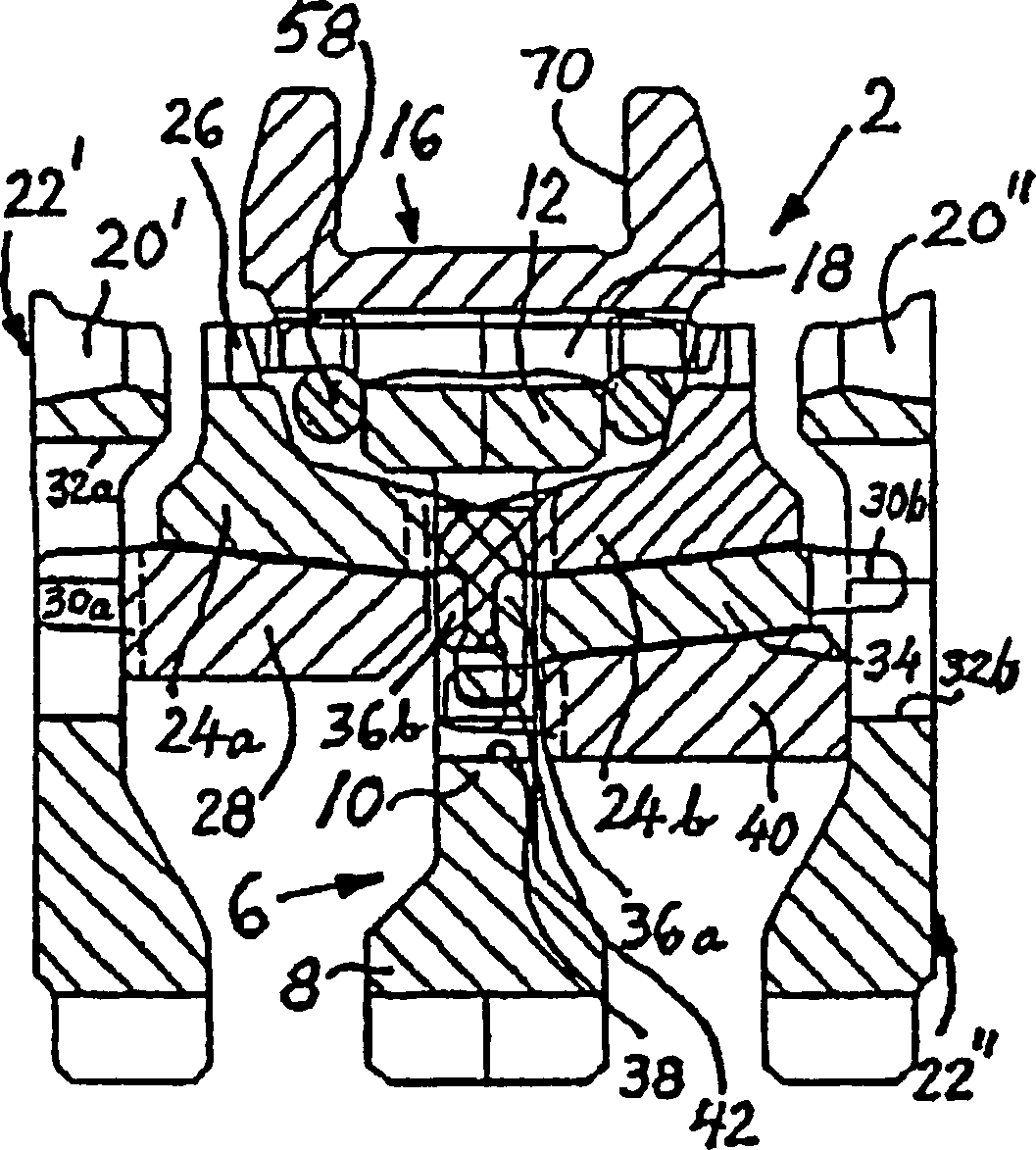

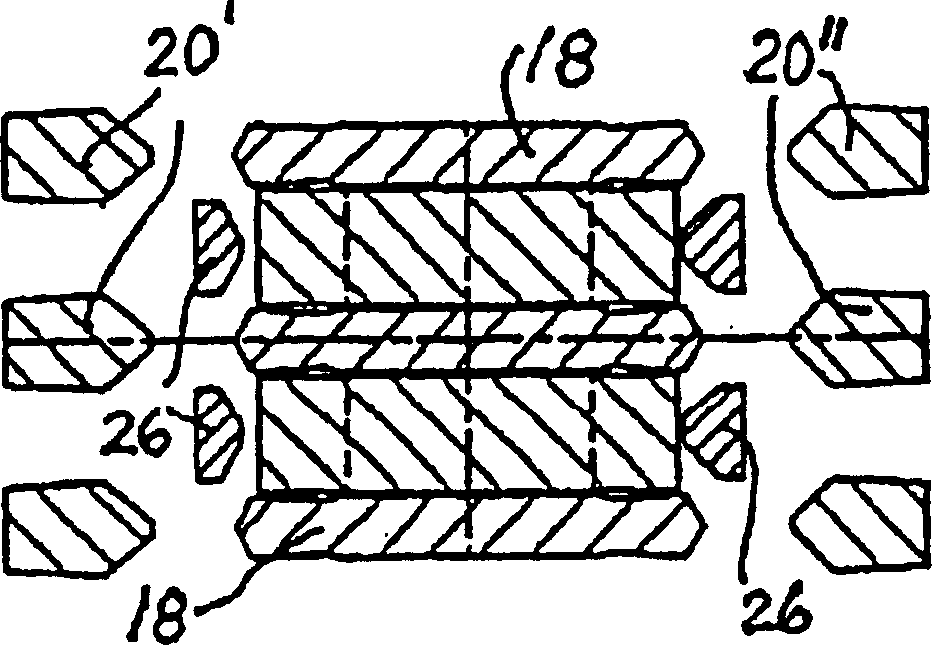

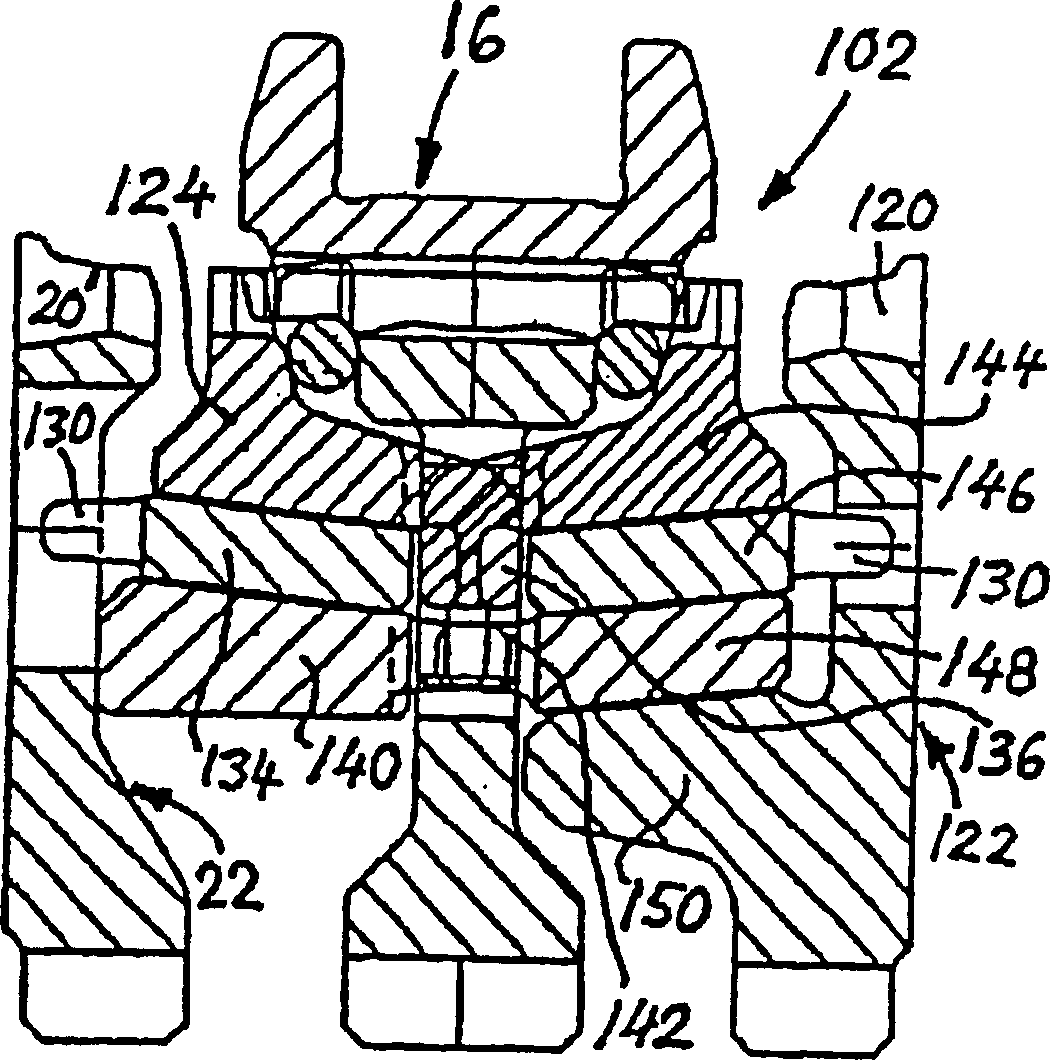

[0038] figure 1 A first synchronizing device 2 is shown, which is constructed from the constituent system according to the invention and contains a carrier element 6 which can be fitted on a rotatable gearbox shaft 4 and is fitted to the shaft 4 co-rotate, while said carrier element 6 comprises a hub 8 connectable to the shaft 4 (only shown in FIGS. 25-26 ) and spokes 10 projecting radially from said hub 8 . On the outer circumference of the spokes, the load-bearing element 6 has an outer part 12 which widens axially to the side and is provided on the outside with axial load teeth 14 (see Figure 13A ). On the outside of the outer part 12, the carrier element supports a sliding sleeve 16 (see Figure 21 ), the sliding sleeve 16 is mounted to rotate with the carrier element, but can move axially relative to the carrier element and surrounds the carrier element in an annular manner. The inside of the sliding sleeve is provided with axially ridged connecting teeth 18 which eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com