Foam fixed hot melt device

The technology of a hot-melt device and foam is applied in the field of devices where the outer wall of the speaker is attached to the foam, which can solve the problems of easy falling off of the foam, affecting the sound insulation effect, etc., and achieve the effect of increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

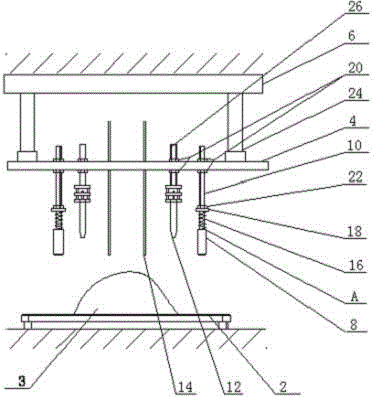

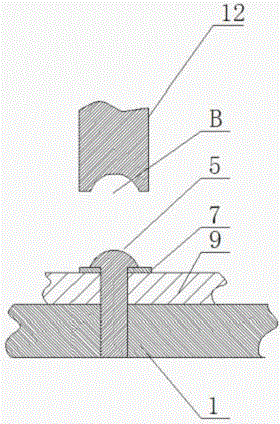

[0027] Such as figure 1 and figure 2 As shown, the present invention comprises workbench 2, and described workbench 2 is provided with arched boss 3, and above described boss 3 is also provided with elevating device, and the lower surface of described elevating device is connected with pressing device, heating device and cooling device.

[0028] After the horn 1 is positioned on the boss 3 on the workbench 2, adjust the lifting device so that the pressing device presses the horn 1 tightly to prevent it from moving. The foam 9 is also provided with a gasket 7 passing through the dry plastic rod 5 above the foam 9, and the plastic rod 5 is heated by a heating device to melt and attach to the surface of the gasket 7 to prevent the foam 9 from moving. Then it is cooled by cooling device.

[0029] The lifting device includes a connecting plate 4 that can move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com