ES fiber spunlace non-woven fabric rotary flexo press

A technology of spunlace non-woven fabric and flexo printing machine, which is applied in the direction of liquid/gas/steam removal by air jet method, which can solve the problems of insufficient drying effect of ES fiber spunlace non-woven fabric and affecting the printing process, etc. Achieve the effect of improving the drying effect and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

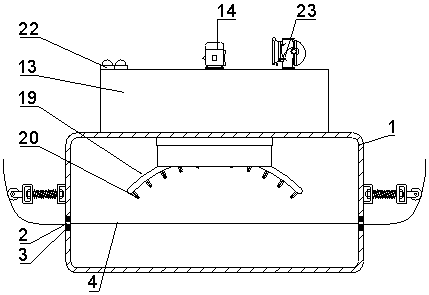

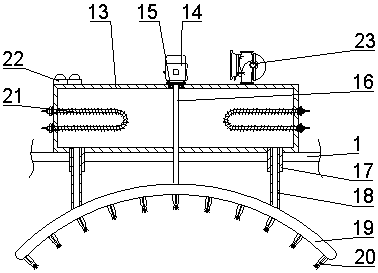

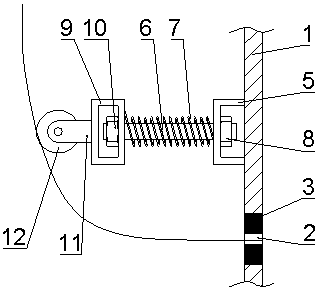

[0018] see Figure 1-3 , an ES fiber spunlace non-woven fabric flexo printing machine, comprising a box body 1, the two side walls of the box body 1 are respectively provided with inlet and outlet ports 2, and the surfaces of the left and right sides of the box body 1 are respectively fixedly connected with A C-shaped frame 5, a threaded column 6 runs through the C-shaped frame 5, and a first nut 8 is screwed on the threaded column located in the C-shaped frame 5, and the other end of the threaded column 6 moves through a mouthed frame 9, The end that is positioned at the threaded hole 6 in mouthpiece frame 9 is screwed with second nut 10, and the surface of described mouthpiece frame 9 is fixedly connected with mounting plate 11, and is rotatably connected with guide wheel 12 on mounting plate 11, and described screw thread The column 6 is sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com