Horizontal shaft wind turbine blade self-adaptive elastic variable pitch device

A technology of wind turbine blades and fan blades, which is applied in the directions of wind engines, wind engines, and wind engine control in the same direction as the wind. problem, to achieve the effect of overcoming power and overload, stable power output, and high-efficiency wind energy extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

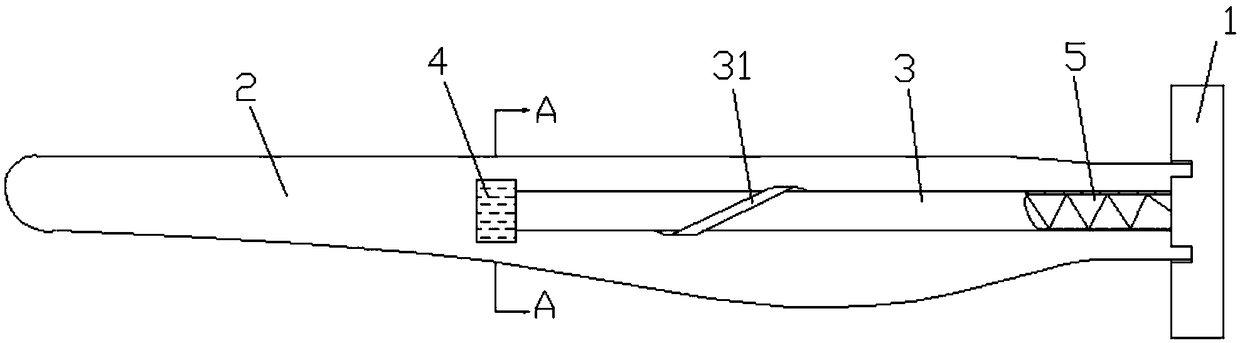

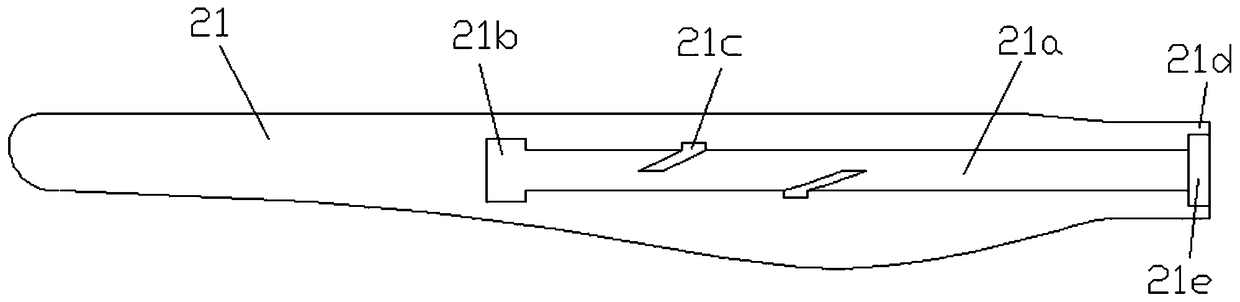

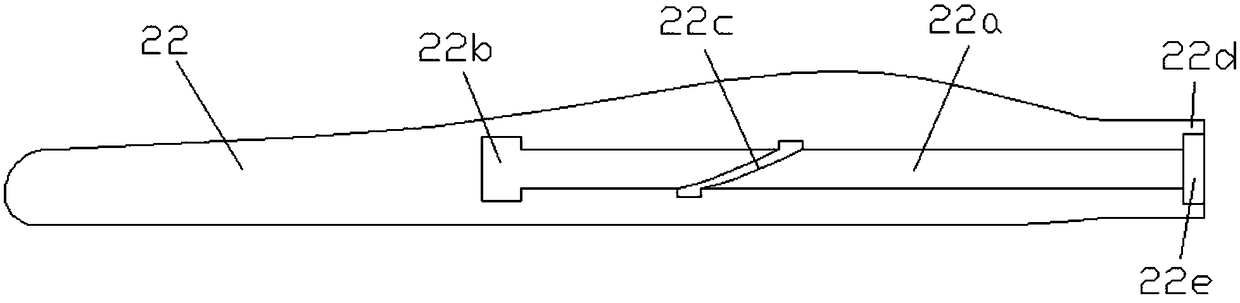

[0026] Figure 1 to Figure 6 It is a schematic diagram of the principle and structure of the embodiment of the present invention.

[0027] The reference signs are: flange 1, closed annular groove 1a, fan blade installation block 11, fan blade 2, left half blade 21, left half sleeve cavity 21a, left half flange block positioning cavity 21b, Left concave torsion track groove 21c, left assembly convex ring 21d, left positioning cavity 21e, right half blade 22, right half sleeve cavity 22a, right half flange block positioning cavity 22b, right concave torsion track groove 22c, right assembly convex The ring 22d, the right positioning cavity 22e, the guide sleeve 3, the convex torsion track 31, the flange block 4, and the spring damper 5.

[0028] The invention discloses an adaptive elastic pitch device for horizontal-axis wind turbine blades, which in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com