A macro-micro-driven linear piezoelectric motor and its driving method

A piezoelectric motor and macro-micro drive technology, applied in the field of motor research, can solve the problems of inaccurate realization and limited application scope, and achieve the effects of simple processing, convenient design and debugging, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

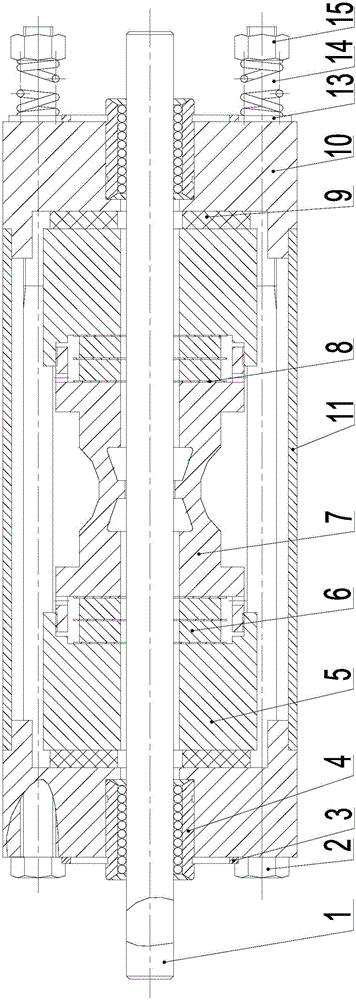

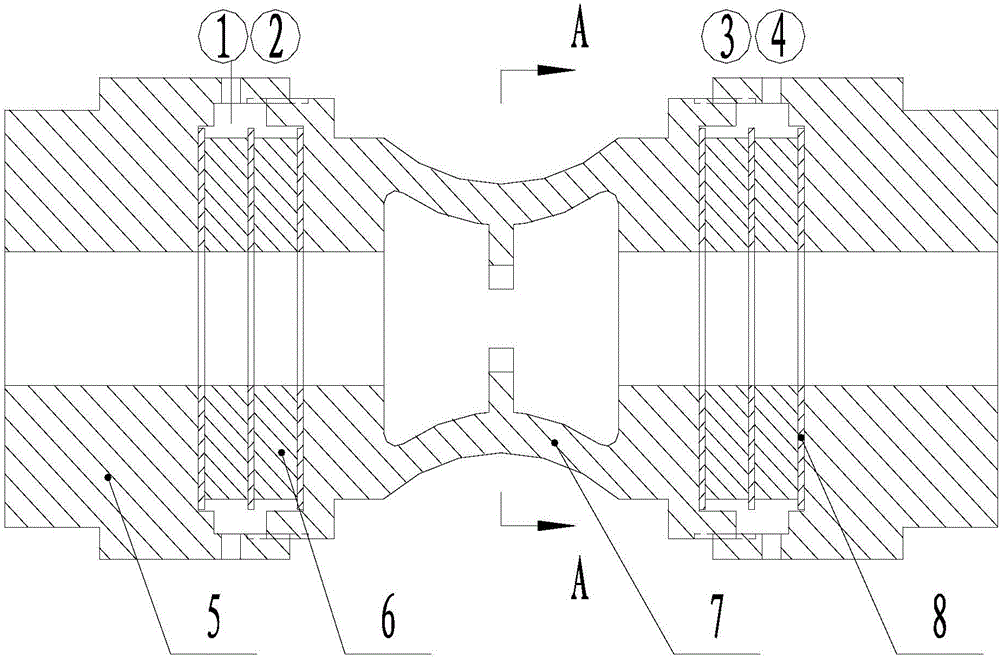

[0042] Such as figure 1 As shown, a macro-micro drive linear piezoelectric motor includes a frame, a driving vibrator, a mover 1, and a pre-tightening mechanism for locking the frame, driving the vibrator, the mover 1, and adjusting the pre-tightening force. In the example, the frame includes a frame plate 11, a frame cover 10, and a pre-tightening mechanism includes a fastening bolt 2, a rubber washer 9, a flat washer 13, a cylindrical spring 14, a fastening nut 15, and so on. The pre-tightening mechanism changes the feed depth of the fastening bolt 2 and the elastic deformation of the rubber gasket 9 to give a certain pre-tightening force to the motor stator. Both ends of the frame are provided with rolling linear ball bearings 4, an elastic retaining ring 3 is arranged between the bearing 4 and the frame cover 10, the mover 1 is a constant radius cylindrical guide rod, and the mover 1 passes through the two bearings and the driving vibrator The hole in the middle, through th...

Embodiment 2

[0058] The structure of this embodiment is the same as that of Embodiment 1 except for the following features: the driving vibrator of this embodiment is as Image 6 , 7 8. As shown in 8, the metal elastic body 25 at each end of the drive vibrator is divided into two parts, and the outer surface of the end close to the frame cover is a hexagonal prism structure. This structure can be used as a wrench position when fixing, and can be used for micro displacement amplification. The outer surface of one end of the elastic body connection is a cylinder, and the outer surface is provided with an outer thread. The micro-displacement amplifying elastic body 27 is provided with an inner thread, and the inner thread is provided with a notch for the lead wire to draw the micro-displacement amplifying elastic body. The terminal 28 is led out from this gap. The piezoelectric ceramic disc 26, the metal elastic body 25 and the micro displacement amplifying elastic body 27 are fastened together...

Embodiment 3

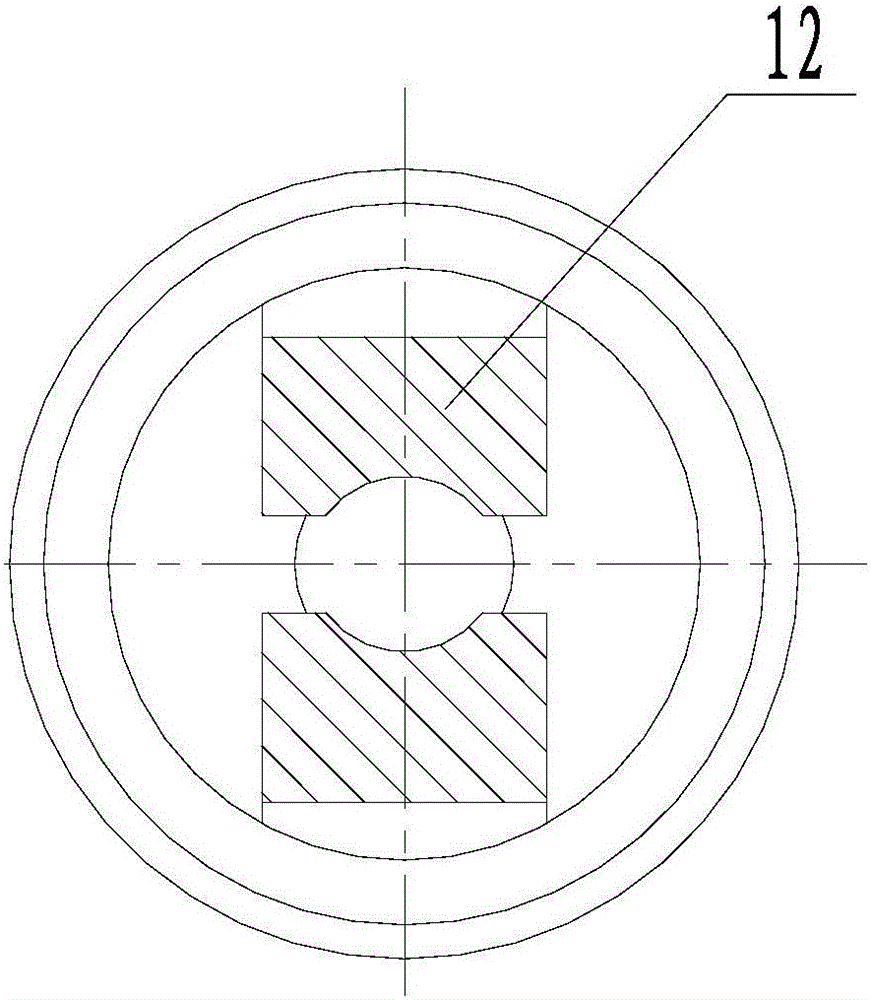

[0061] The structure of this embodiment is the same as that of Embodiment 2 except for the following features: the driving vibrator of this embodiment is as Picture 9 , 10 11. As shown in 11, the outer surface of the metal elastic body 35 in the driving vibrator is a cylinder, and the outer surface of the metal elastic body 35 and the micro-displacement amplifying elastic body 37 are both provided with bosses, which are passed through the fastening bolt 33 and the fastening nut 34 connection. In practical applications, in order to facilitate the connection of bolts, both the micro-displacement amplifying elastic body and the metal elastic body can be designed as variable diameter cylinders as required. A convex tooth 312 is provided in the middle of the inner side of the micro-displacement amplifying elastic body hole 37, and the convex tooth 312 is in frictional contact with the mover during driving, and the contact area between the two is the driving area.

[0062] The install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com