hydraulic pump

A technology of hydraulic pump and rotating shaft, applied in the field of hydraulic pump, can solve the problems of wear and tear of pre-pressure applying parts, and achieve the effect of inhibiting wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

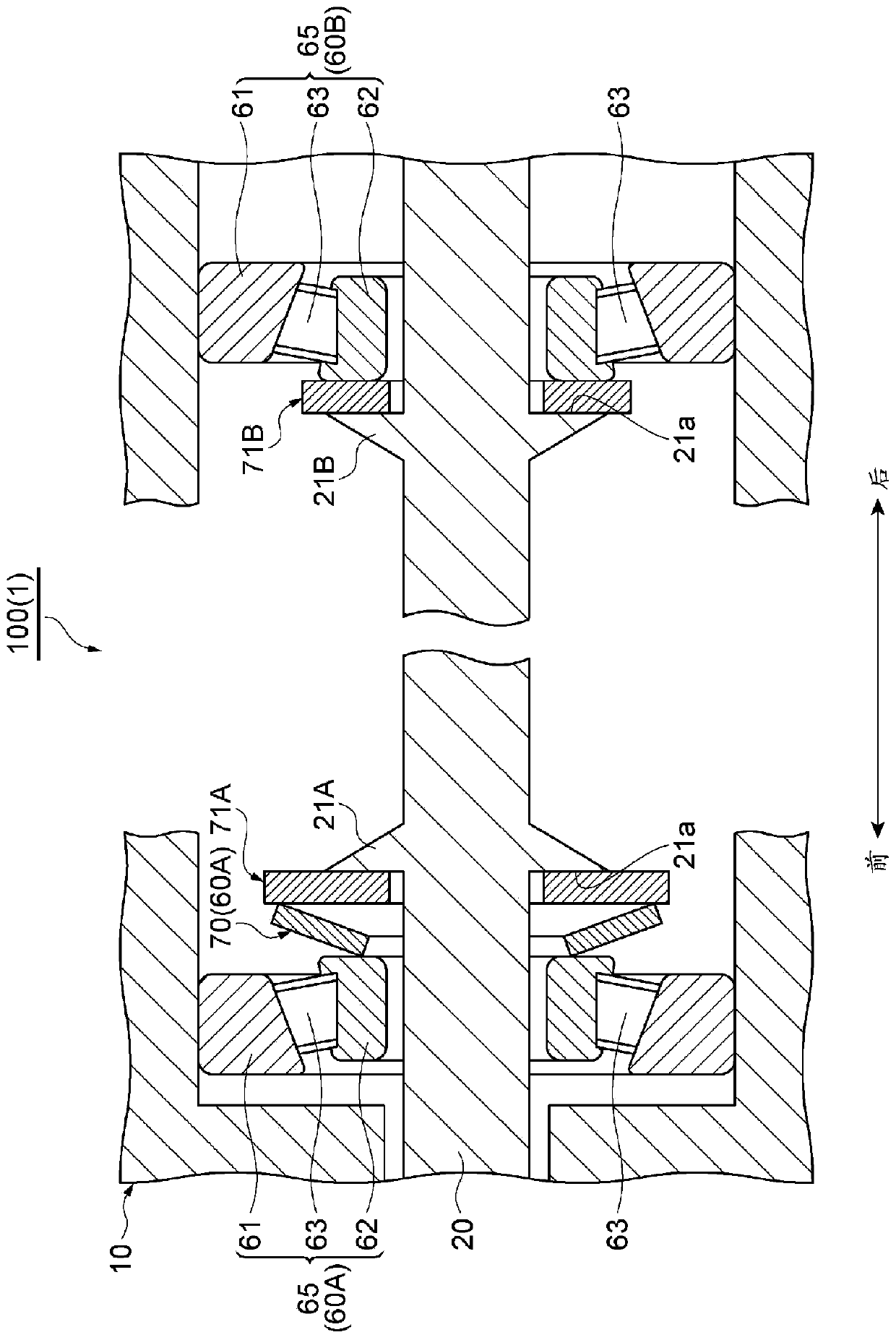

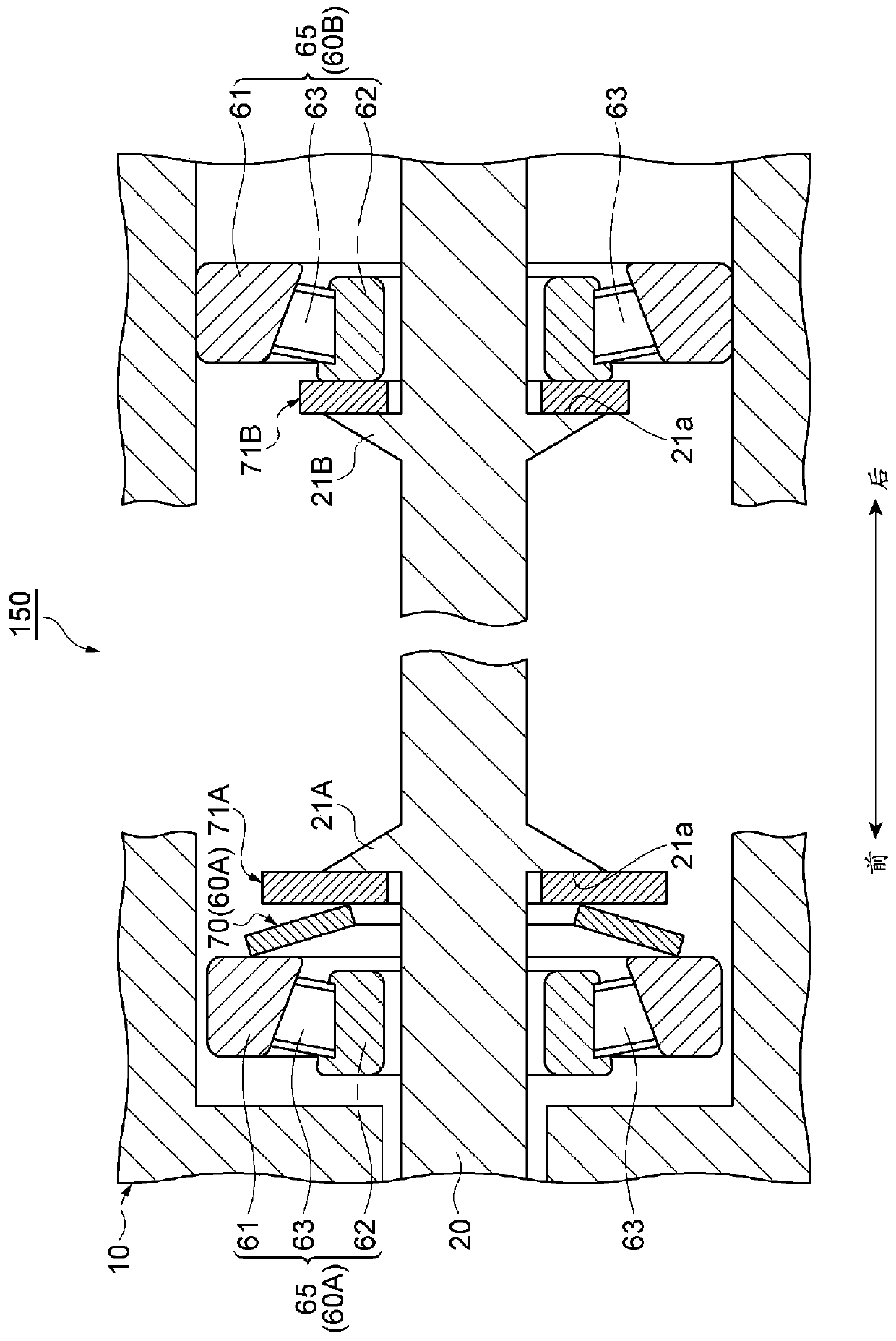

[0017] Embodiments for implementing the present invention will be described in detail below with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same or an equivalent member, and when the content to explain overlaps, this description is abbreviate|omitted.

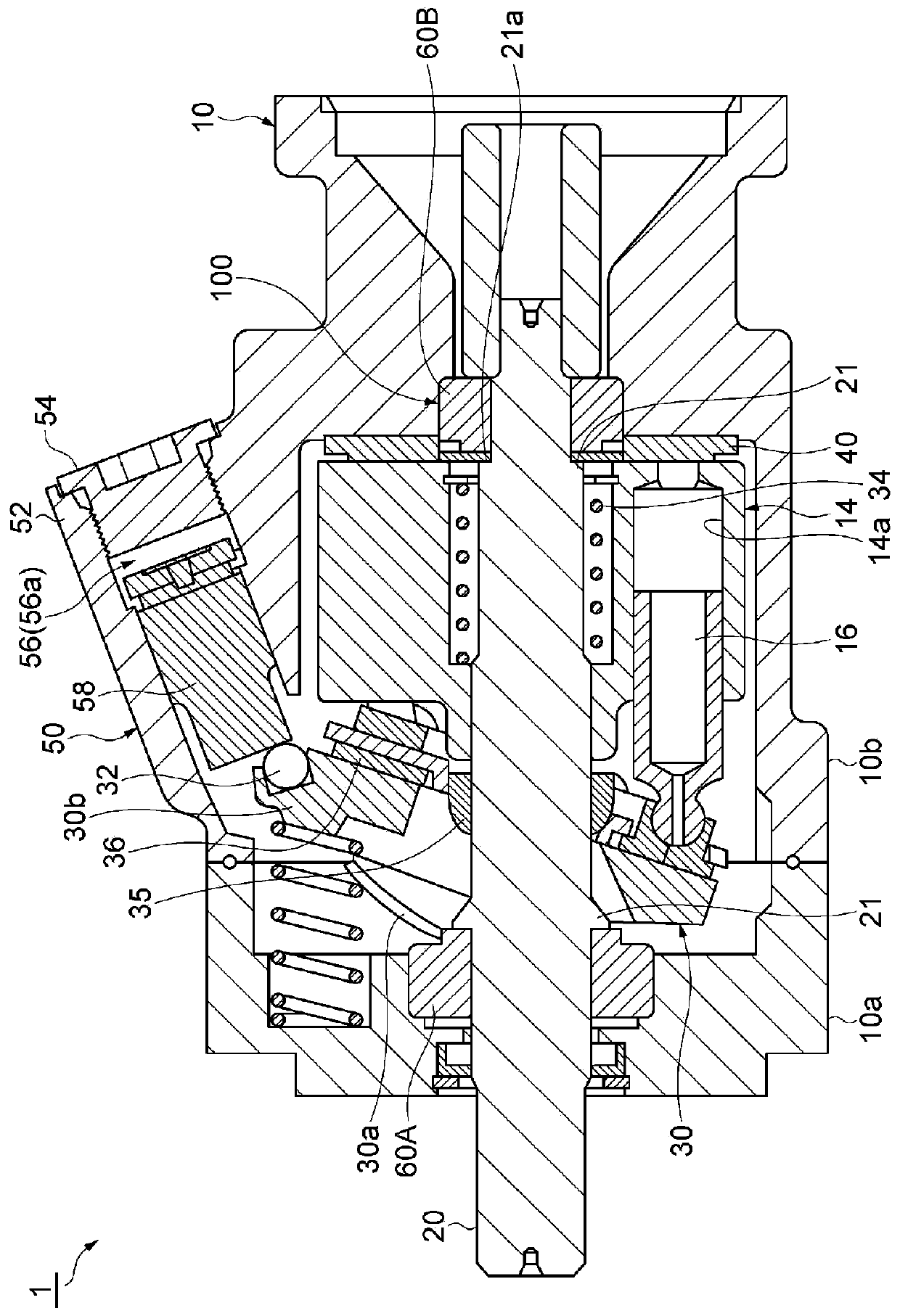

[0018] First, the configuration of the hydraulic pump of the present embodiment will be described. As an example of a hydraulic pump, see figure 1 The variable displacement piston pump (hereinafter simply referred to as hydraulic pump) 1 will now be described.

[0019] The hydraulic pump 1 includes: a pump housing 10 (housing), a rotating shaft 20 supported rotatably by the pump housing 10 and having a protruding end portion protruding from the pump housing 10, having a plurality of cylinder holes 14a in the circumferential direction of the rotating shaft 20, and The cylinder block 14 integrally rotating with the rotating shaft 20, the piston 16 provided slidably in the plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com