Multi-station flexible hairy crab shaping and binding all-in-one machine and its use method

A hairy crab and integrated machine technology, which is applied to the parts, conveyors, and bundling objects of bundling machinery to achieve the effects of improving simplicity, increasing productivity and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

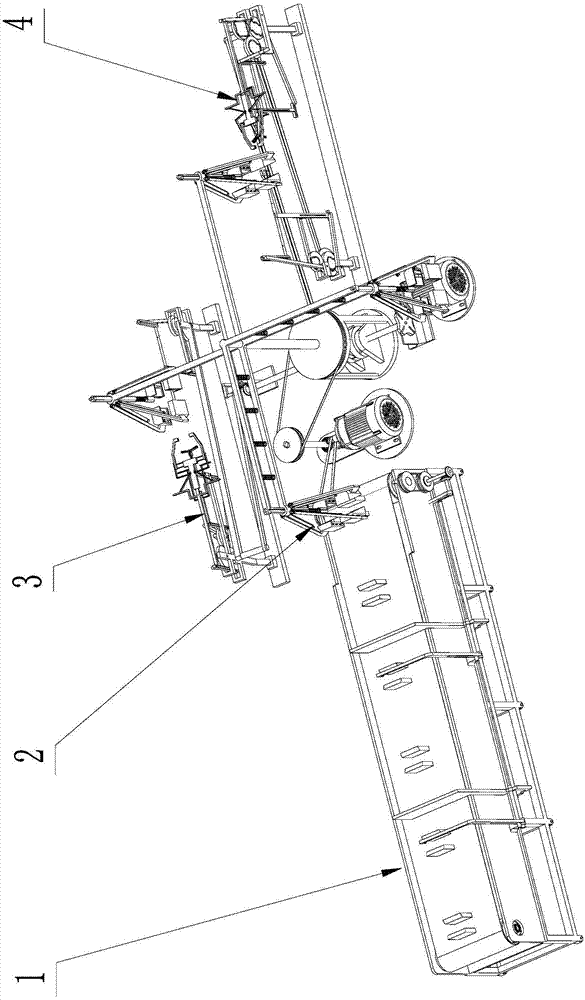

[0082] figure 1 General axonometric view of the invention. It includes a conveying straightening mechanism 1, a grabbing fixture 2, a horizontal rope-tying mechanism 3 and a longitudinal rope-tying mechanism 4. Among them, the conveying straightening mechanism 1 is located on the far left, and the grabbing fixtures are four identical clamping molds, three of which are located at the right end of the conveying straightening mechanism 1, the upper end of the horizontal rope-tying mechanism 3, and the longitudinal rope-tying mechanism 4 the upper end. There are four stations respectively, and the last station packs boxes. The four stations rotate clockwise to complete the clamping, horizontal tying, vertical tying and packing of hairy crabs.

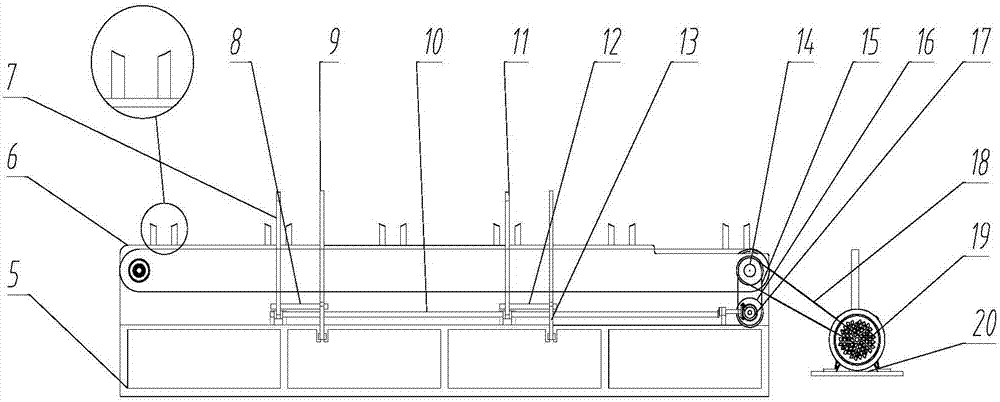

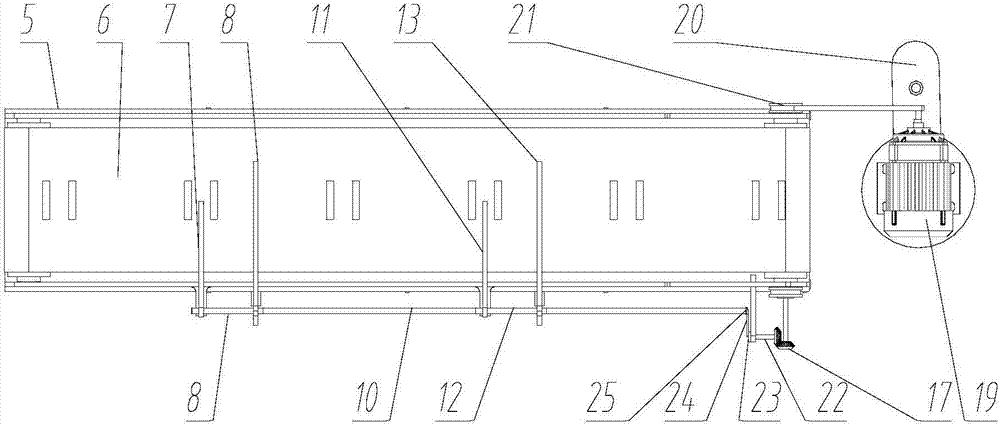

[0083] figure 2 It is the front view of the delivery straightening mechanism of the present invention. The figure shows that the conveyor belt 6 with the boss is connected to the frame 5 through the transmission shaft and the belt rol...

Embodiment 2

[0119] The difference between this embodiment and embodiment 1 is:

[0120] In Embodiment 1, the hairy crab fixing platform is replaced. The hairy crab fixing platform is an octagonal prism boss with rivet holes at the bottom, and an ellipsoidal groove on the upper part of the boss for placing hairy crabs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com