Two-way ball valve with cold-drawn integral valve body and preparation method of two-way ball valve

A two-way ball valve and integral valve technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of difficult maintenance, unstable opening and closing torque of the ball valve, high cost, and reduce manufacturing costs and maintenance costs. The effect of reducing welding quality risk and welding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

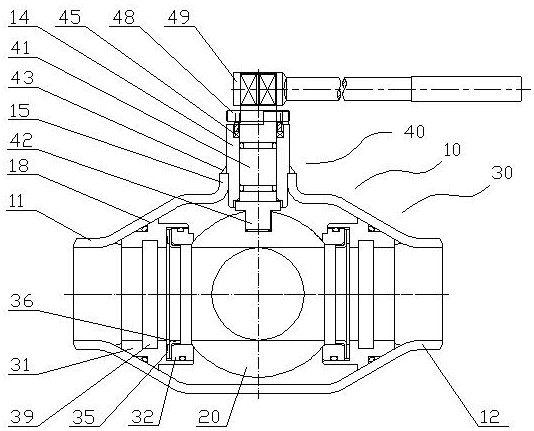

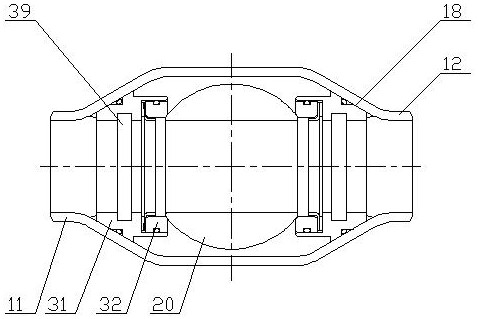

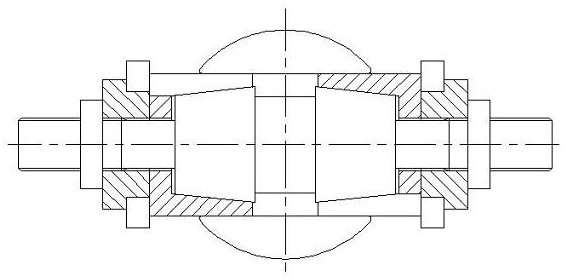

[0031] see Figure 1-4 , the two-way ball valve with a cold-drawn integral valve body includes an integral valve body 10, the integral valve body includes a left connecting pipe 11 and a right connecting pipe 12, and the top of the integral valve body is provided with a vertical stem sleeve or a vertical A nozzle-shaped valve stem socket 15, the valve stem socket main body 14 is plugged into the valve stem socket, and the valve stem socket main body and the valve stem socket are welded together, because the valve stem socket main body and the valve The plug joints of the tubular structure are adopted between the rod sockets, and the weld 43 between the two is a horizontal circular fillet weld, which avoids the original difficult horizontal intersecting line fillet weld.

[0032] The valve stem sleeve interface or valve stem sleeve on the integral valve body is connected to other parts of the valve body through a smooth transition surface to adapt to the characteristics of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com