Central hot water circulating system of gas water heater

A gas-fired water heater and circulation system technology, applied in fluid heaters, lighting and heating equipment, mechanical equipment, etc., can solve problems such as heavy workload, inability to realize mixed water, heavy installation and debugging workload, etc., and achieve the goal of reducing workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

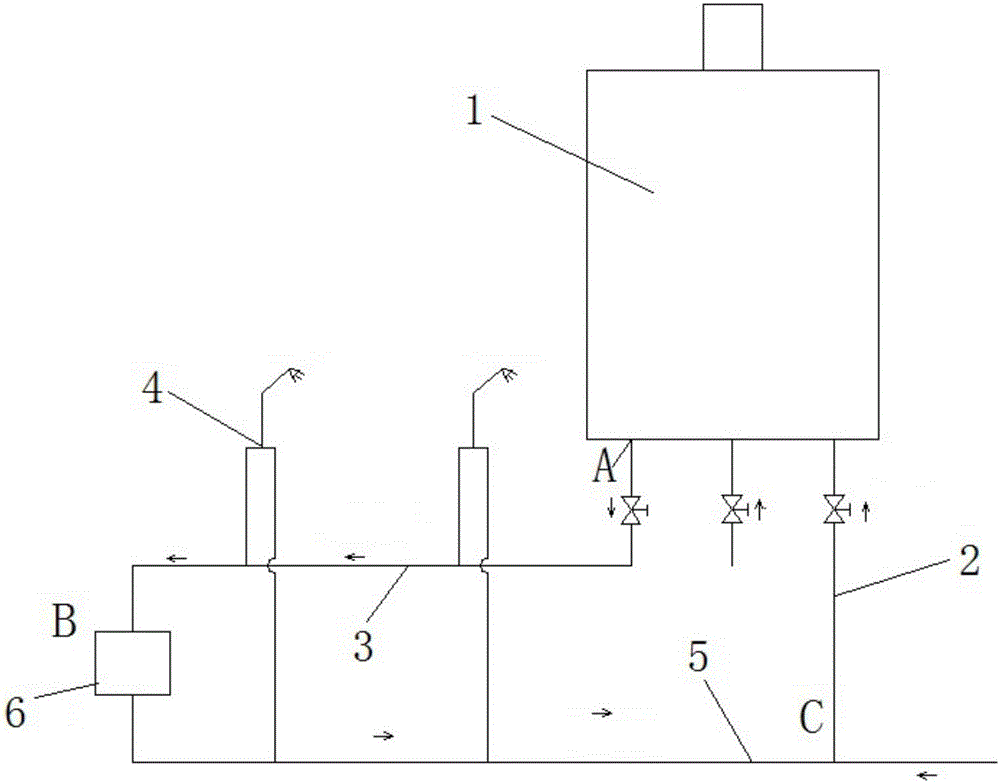

[0028] Such as figure 1 As shown, a gas water heater central hot water circulation system includes: a gas water heater 1, a cold water inlet pipe 2 connected to the gas water heater 1, a hot water outlet pipe 3, and several water points 4 connected to the hot water outlet pipe 3 , and the cold water branch pipe 5 connected between each water point 4 and the cold water inlet pipe 2; it is characterized in that a hot water circulation device 6 is connected between the outlet hot water pipe 3 and the cold water branch pipe 5 at the farthest water point. .

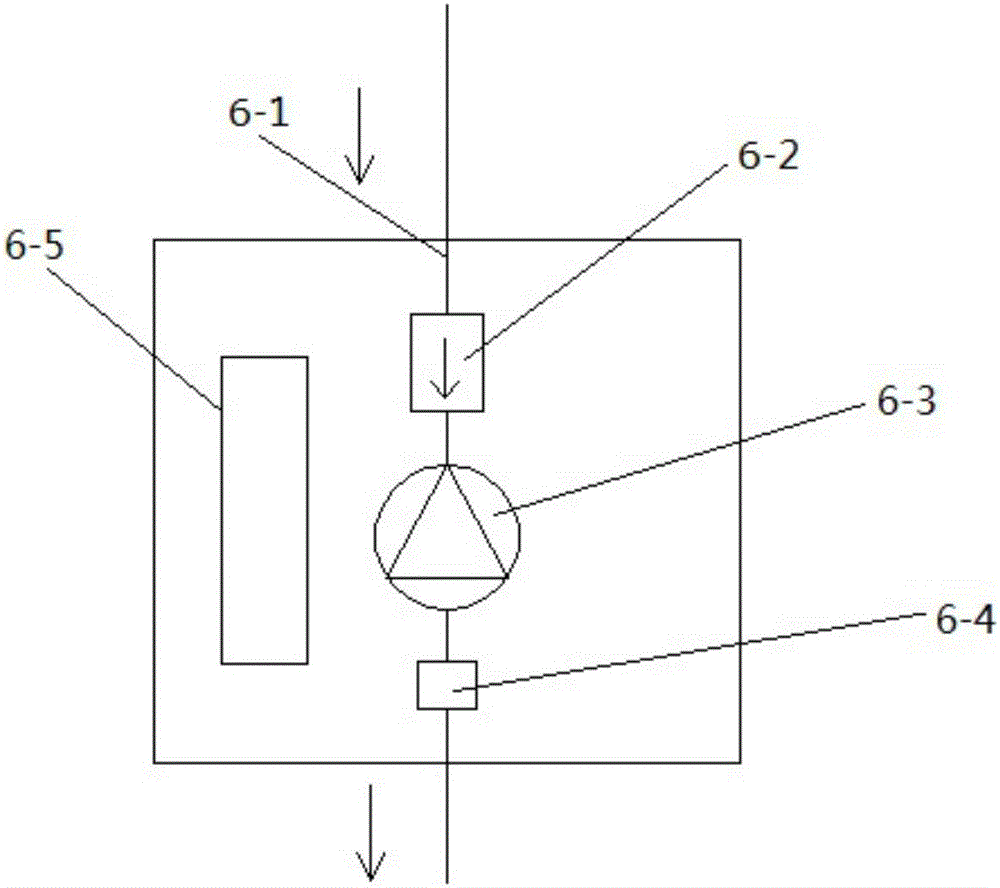

[0029] Such as figure 2 As shown, the hot water circulation device 6 includes: a connecting pipeline 6-1, a one-way valve 6-2 connected in series on the connecting pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com