A method for measuring track flatness

A measurement method and flatness technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of large measurement error, cumbersome process, hidden safety hazards, etc., to achieve stability and flatness guarantee, easy and safe operation, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

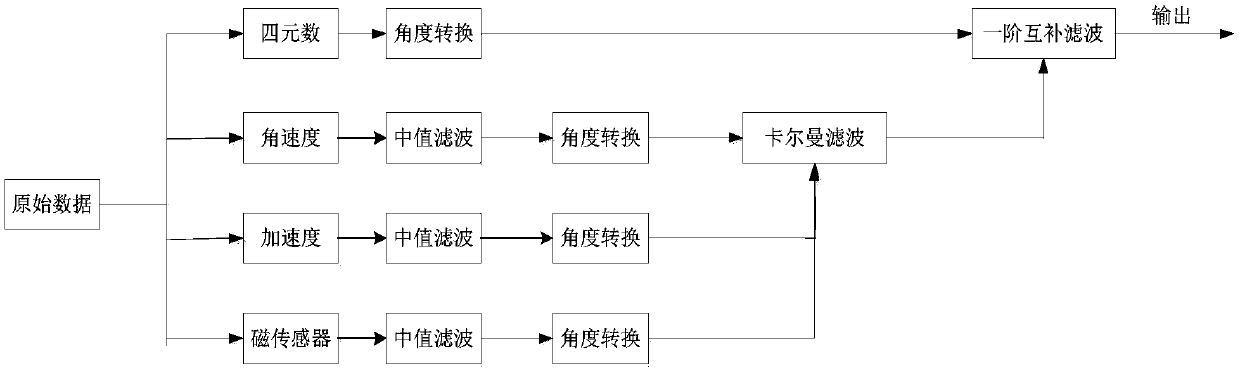

Method used

Image

Examples

Embodiment Construction

[0025] The walking mechanism of the present invention can adopt the robot walking mechanism provided by the invention patent with the application number of 201610186221.1. The walking mechanism uses a high-performance brushed motor as power, and there is a positioning system under the driving wheel, combined with the motor encoder The position ring can be accurate The walking distance is collected. The walking mechanism has eight guide wheels. At both ends of the walking mechanism and the track, there are four guide wheels. Turn a certain angle on the horizontal plane to adapt to the steering adjustment, which can realize steering without dead angle, and no force in the direction of motion will be generated at the turning. A positioning system is installed on the walking mechanism, and 9 magnetic steels are used to cooperate with the Hall sensor to achieve non-contact. When the track does not need to be installed with power supply, the walking distance of the positioning mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com