Coupling indirect type millimeter wave phase detector for silicon-based known frequency gap

A phase detector, millimeter wave technology, applied in the phase angle between voltage and current, electric power measurement by thermal method, instruments, etc., can solve the problems of high cost, low integration, complex structure, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific implementation plan

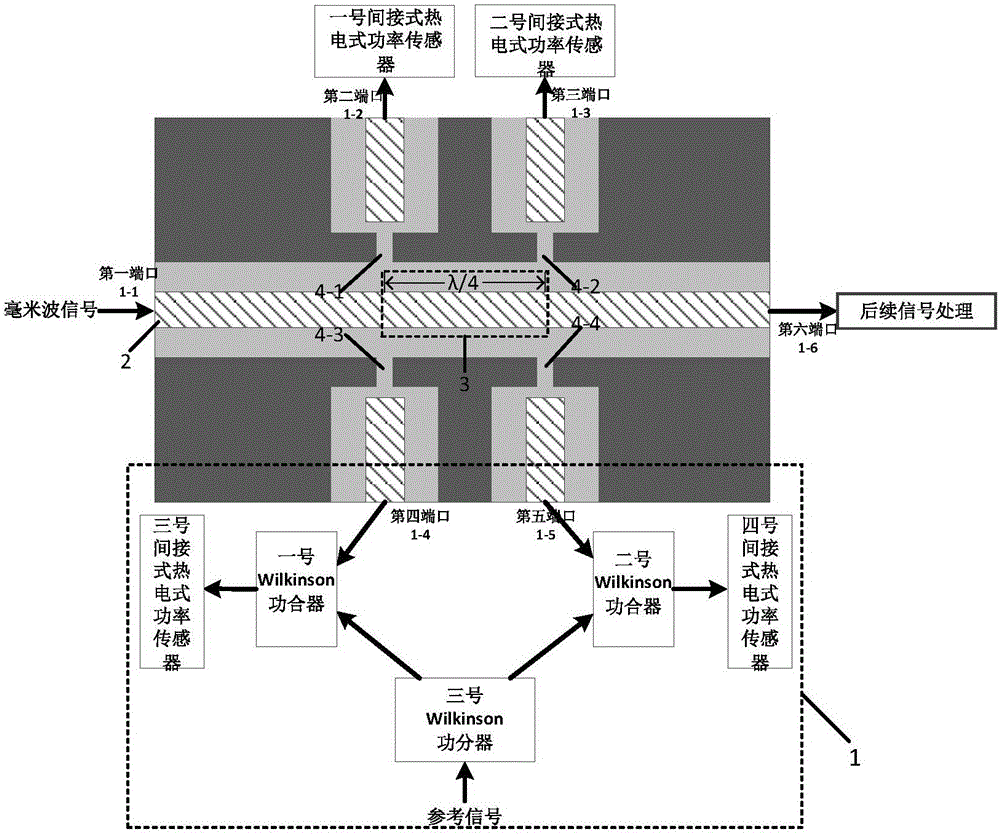

[0018] The silicon-based known frequency slot-coupled indirect millimeter wave phase detector of the present invention is made based on a high-resistance Si substrate 11, and is made of coplanar waveguide 2, No. 1 slot coupling structure 4-1, No. 2 slot coupling structure 4-2, No. 3 slot coupling structure 4-3, No. 4 slot coupling structure 4-4, phase shifter 3, a Wilkinson power splitter, two Wilkinson power combiners and four indirect thermoelectric power sensors .

[0019] The structure of the Wilkinson power divider and the Wilkinson power combiner are the same, mainly composed of a coplanar waveguide 2, asymmetric coplanar strip line 13 and a resistor 5. Two asymmetric coplanar strip lines 13 of the same length can be The millimeter wave signal on the planar waveguide 2 is divided into two equal parts, and the resistor 5 is located at the end of the two asymmetric coplanar strip lines 13.

[0020] An indirect thermoelectric power sensor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com