A kind of manufacturing method of anti-glare cover plate

A manufacturing method and cover plate technology, which is applied to the photoplate-making process of pattern surface, optics, optical elements, etc., can solve the problem that the morphology cannot be obtained, and the spatial distribution and intensity of transmitted light or reflected light intensity on the surface of the cover plate cannot be controlled. , cover surface flashing and other problems, to achieve the effect of improving the flashing phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

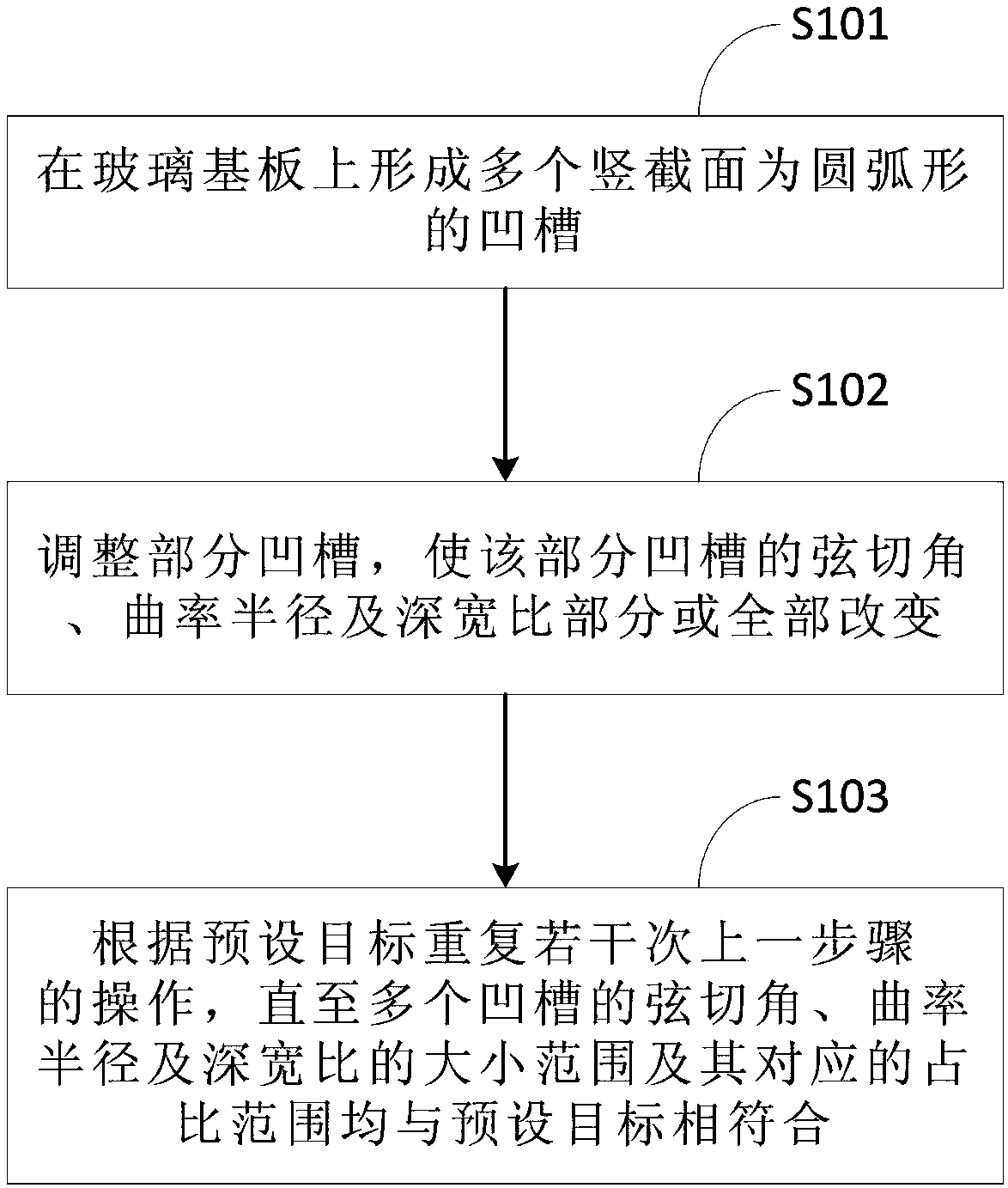

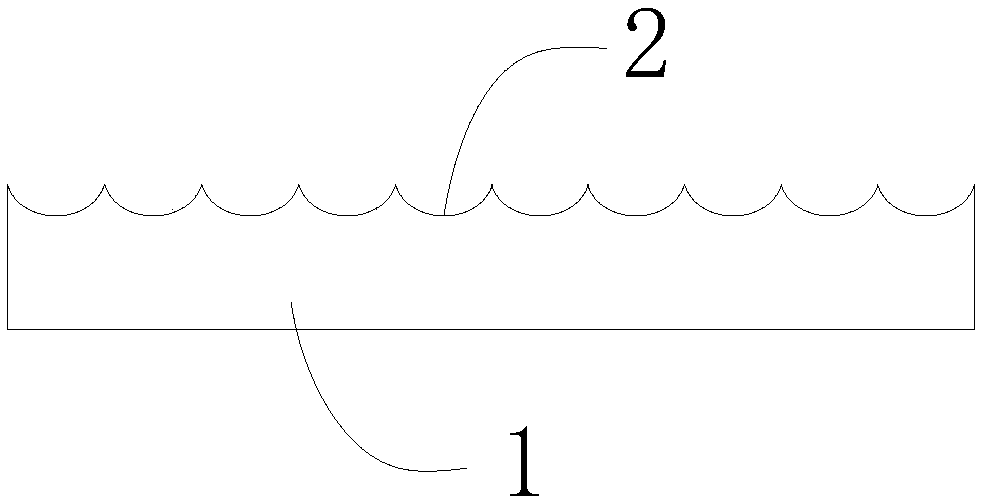

[0052] In general, a method for manufacturing an anti-glare cover plate of the present invention includes the following two steps:

[0053] First, the target size ranges of different structural parameters of the surface structure of the glass substrate 1 and their corresponding target proportion ranges are set according to preset targets.

[0054] Second, a plurality of microstructures are formed on the glass substrate 1, the absolute values of different structural parameters of each microstructure are within the corresponding target size range, and the target size range is divided into For several setting ranges, the ratio of the number of microstructures whose parameter sizes are within the several setting ranges to the total number of microstructures is within the corresponding target proportion range, so that The anti-glare cover plate has an anti-glare effect.

[0055] The present invention will be described in detail below.

[0056] Please refer to figure 1 , figur...

Embodiment 2

[0089] In general, a method for manufacturing an anti-glare cover plate of the present invention includes the following two steps:

[0090] First, the target size ranges and corresponding target proportion ranges of different structural parameters of the surface structure of the glass substrate 10 are set according to preset targets.

[0091] Second, a plurality of microstructures are formed on the glass substrate 10, the absolute values of different structural parameters of each microstructure are within the corresponding target size range, and the target size range is divided into For several setting ranges, the ratio of the number of microstructures whose parameter sizes are within the several setting ranges to the total number of microstructures is within the corresponding target proportion range, so that The anti-glare cover plate has an anti-glare effect.

[0092] The present invention will be described in detail below.

[0093] Please refer to Figure 9 , Figure 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com