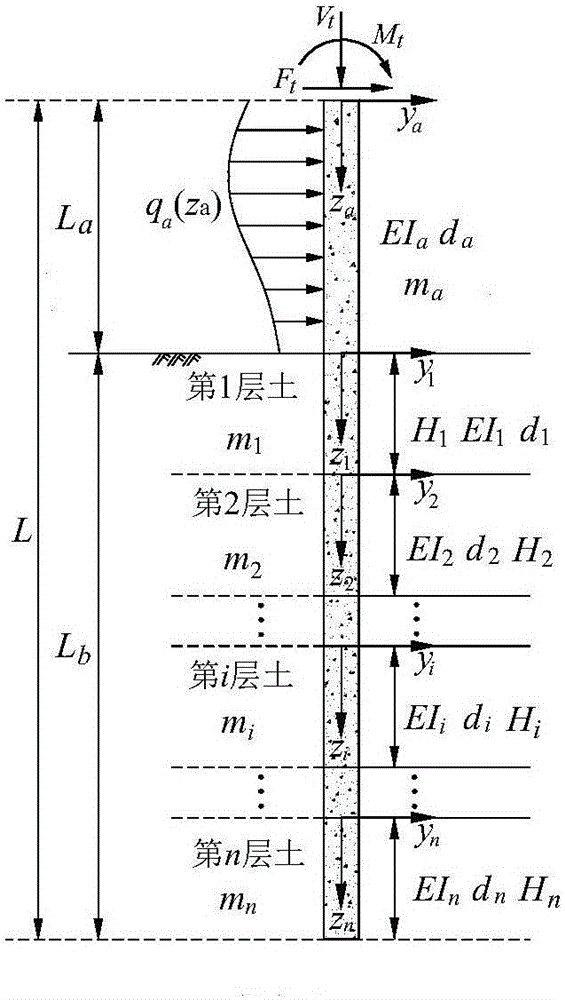

Combined loaded pile bearing capacity transfer matrix general solution method

A technology of transfer matrix and load-bearing piles, which is applied in special data processing applications, complex mathematical operations, instruments, etc., and can solve problems such as limited application range, easy business trips, and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

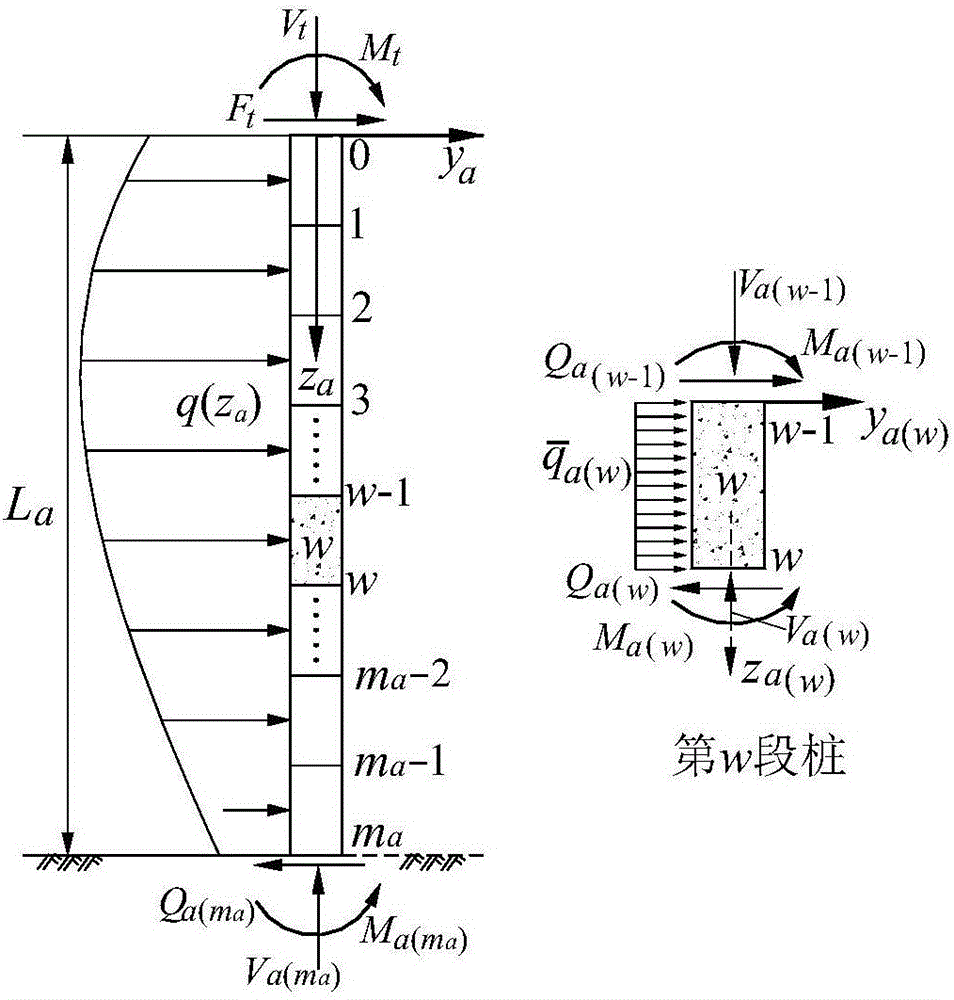

Method used

Image

Examples

Embodiment

[0201] 1. Verify the correctness of the unified p-y curve model

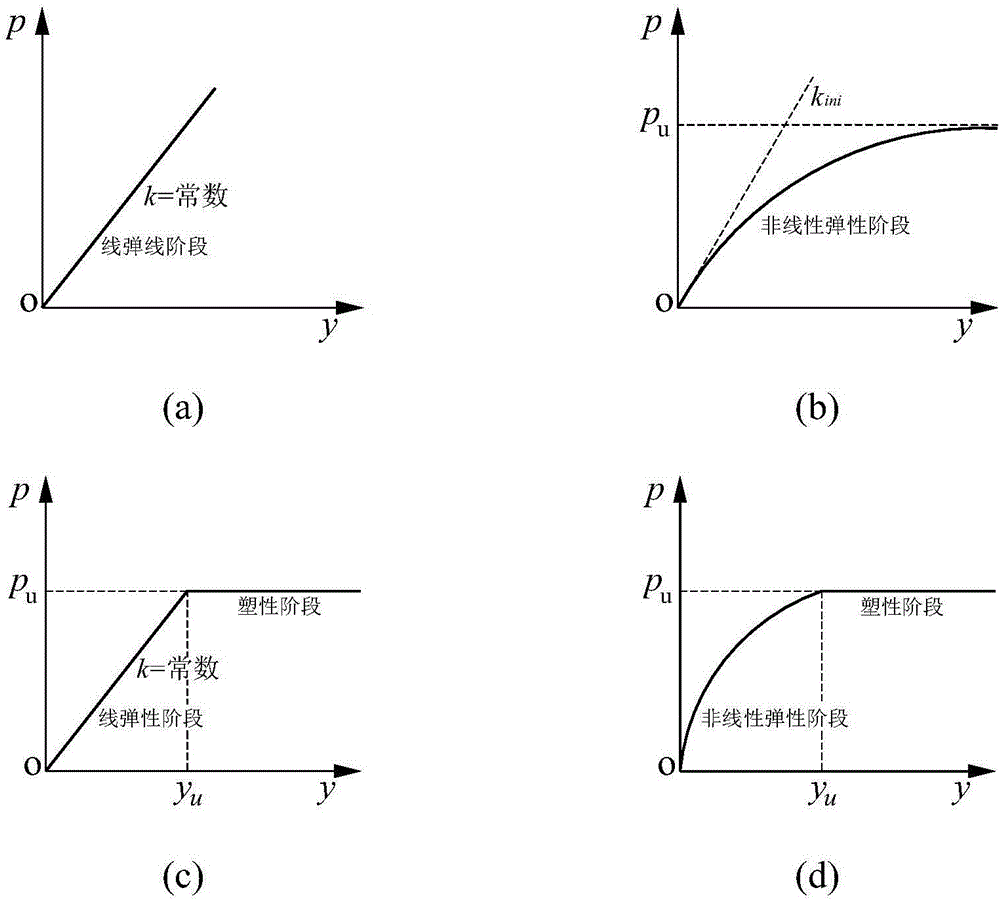

[0202]Since the research literature on the calculation of the bearing capacity of horizontally loaded piles without considering the vertical load is more comprehensive than that of combined loaded piles, based on the special case of combined loaded piles without considering the axial load, the unified expression for the p-y curve is Correctness verification.

[0203] ①Linear elastic model verification

[0204] A constant straight variable section pile is embedded in sandy soil and soft rock. Sand layer thickness H 1 =7.925m, rock thickness H 2 = 12.192m. The soil resistance modulus of the first layer of sandy soil is k 1 =1.04×10 4 z kN / m 2 (z is calculated from the ground); the soil resistance modulus of the second layer of soft rock is k 2 =5.1386×10 4 +5.91×10 3 (z-7.925)kN / m 2 (according to the empirical formula back calculation) and k 2 =4.9573×10 4 +7.419×10 4 (z-7.925)kN / m 2 (Based on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com