A Method of Finding Feature Points of Irregular Shaped 3D Parts

A technology with irregular and feature points, applied in the field of laser cutting machine or robot cutting 3D parts, it can solve problems such as not easy to find and difficult to locate parts accurately, and achieve the effect of simplifying programming and calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

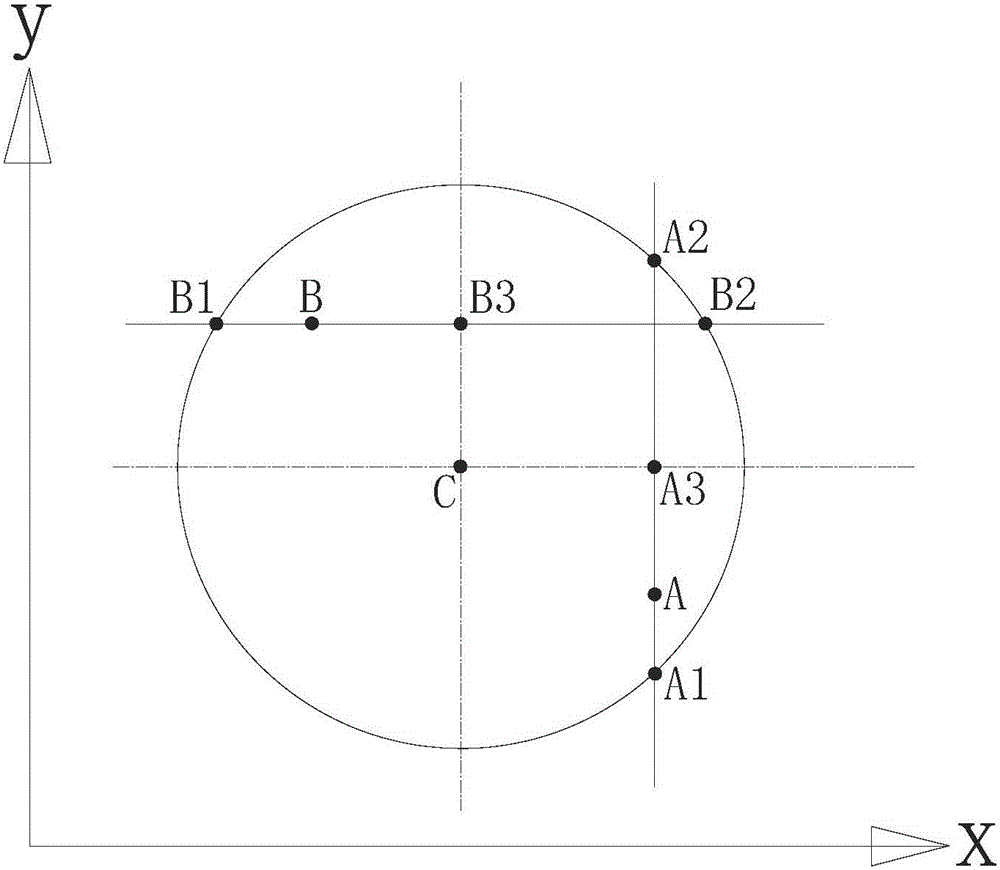

[0017] see figure 1 , the theoretical basis of the method for finding the feature points of the irregular shape three-dimensional part of the present invention has the following two points:

[0018] 1) The laser cutting head with a sensor will stop when it encounters a metal object during the movement, so that the coordinates of the workpiece at this point can be recorded;

[0019] 2) The perpendicular line of any two points on the circumference must pass through the center of the circle, and the intersection of any two diameters of the circle is the center of the circle.

[0020] The method for finding feature points of an irregularly shaped three-dimensional part of the present invention is used for three-dimensional cutting programming of a laser cutting machine or a robot, and the surface of the irregularly shaped three-dimensional part has round holes.

[0021] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com