Transmission line inspection robot obstacle walking device

A technology for inspection robots and power transmission lines, applied in the direction of overhead lines/cable equipment, etc., can solve the problems that inspection workers need to climb mountains and mountains, wading across rivers, low work efficiency and detection accuracy, and complex geographical conditions of transmission lines. , to achieve the effect of low inspection cost, strong climbing and wind resistance, and accurate trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments.

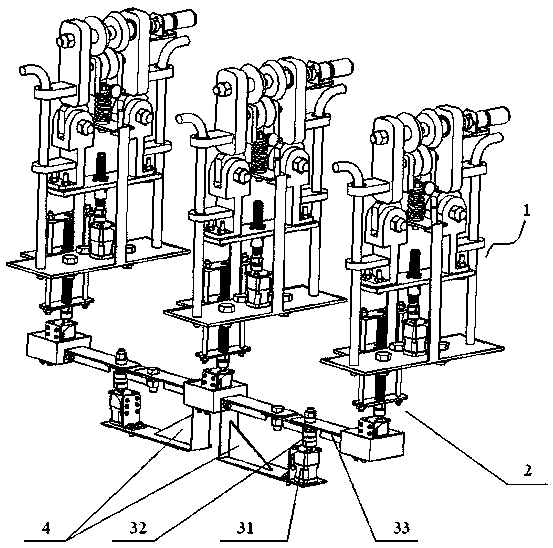

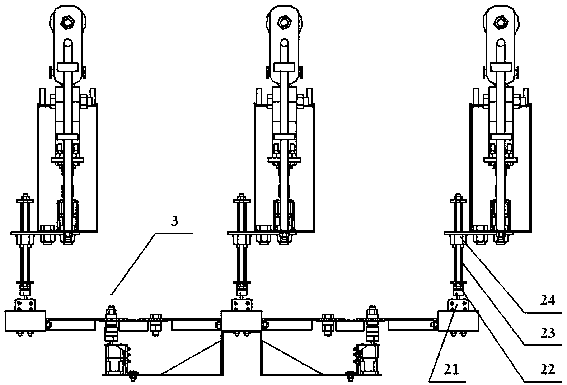

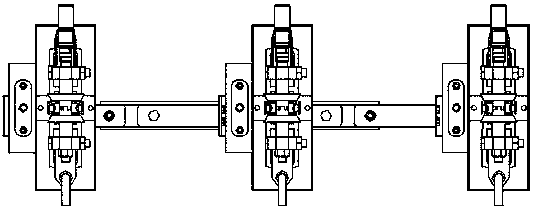

[0031] A power transmission line inspection robot obstacle walking device, its structure is as follows Figures 1 to 4 As shown, it includes a movable frame and three mechanical arms 1, the movable frame is used to support the mechanical arms, and the three mechanical arms 1 are arranged on the transmission line in sequence, and can walk along the transmission line and cross obstacles on the transmission line; A detection device can be installed on the mechanical arm, and with the cooperation of the detection device, the mechanical arm completes the obstacle inspection of the transmission line. In the present invention, the three obstacle-surmounting mechanical arms are successively named forearm, middle arm and rear arm according to the front and rear positions on the power transmission line.

[0032] The movable frame includes a frame 4, a rotating mechanism 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com