Transmission line inspection robot

A technology for inspection robots and transmission lines, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high technical requirements for inspection personnel and pilots, high inspection costs, and short battery life, so as to increase practicability and reliability , Low inspection cost and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments.

[0027] A power transmission line inspection robot, comprising a robot body, a control device and a detection device, the signal output end of the detection device is connected to the input end of the control device, and the output end of the control device is connected to the controlled ends of the controlled components of the robot body; the robot body Under the control of the control device, the detection device completes the obstacle-crossing inspection work of the transmission line.

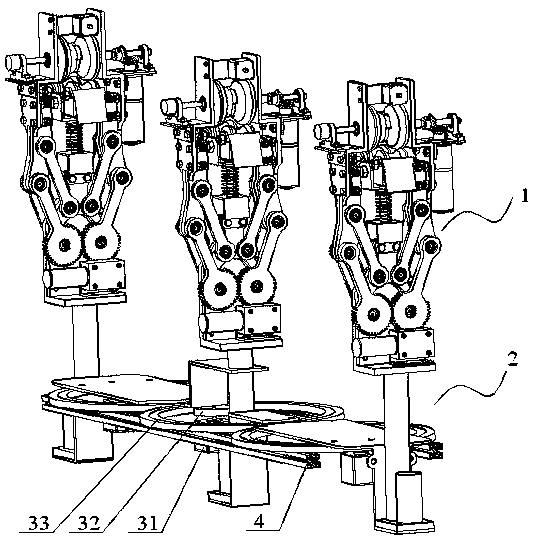

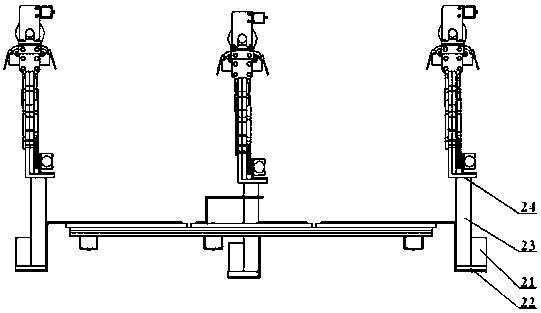

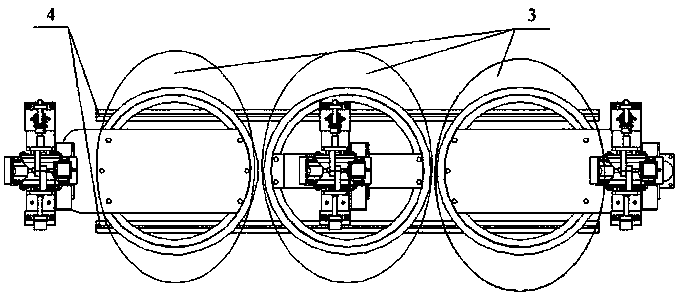

[0028] The structure of the robot body is as Figure 1 to Figure 6 shown. It includes two in-line fixed brackets 4 arranged in parallel, and three sets of motion detection units are arranged side by side on the fixed bracket 4, and each set of motion detection units includes obstacle-crossing mechanical arm 1, up and down movement mechanism 2, and rotation mechanism 3, and rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com