Loudspeaker horn

A loudspeaker and horn technology, which is applied in the field of loudspeaker horns, can solve the problem that the lower limit frequency of the horn of the high-frequency driver cannot meet the needs, and achieve the effects of avoiding off-axis frequency response peaks and valleys, stable sound wave output, and increased intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

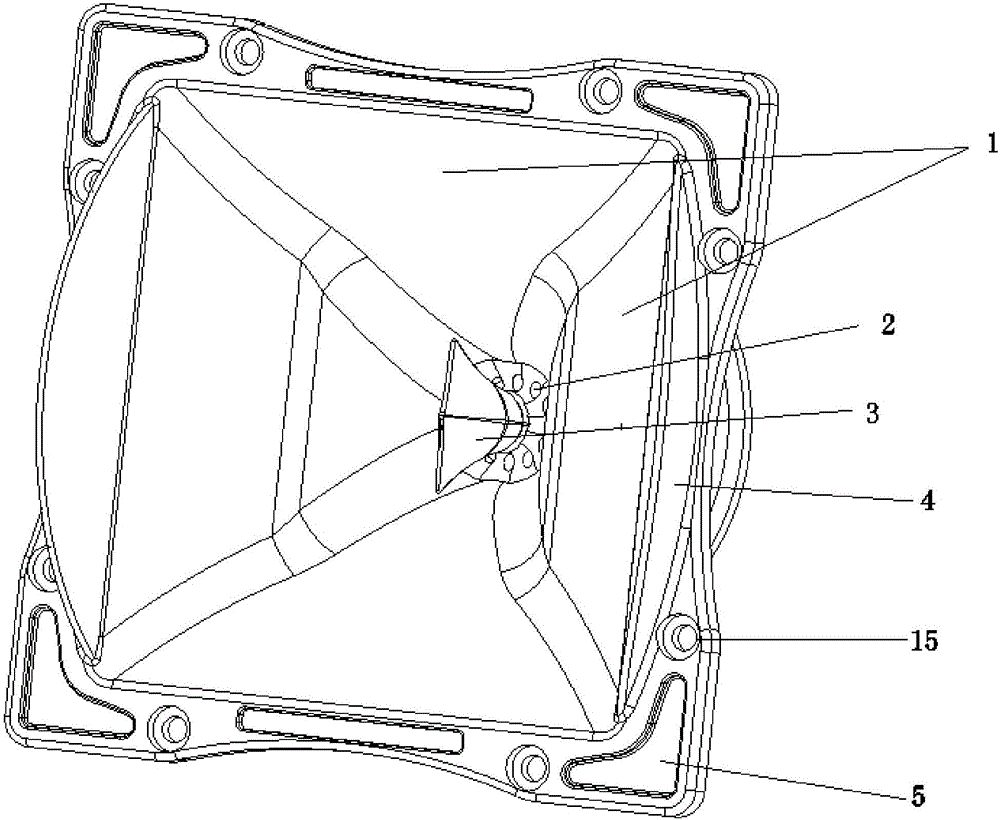

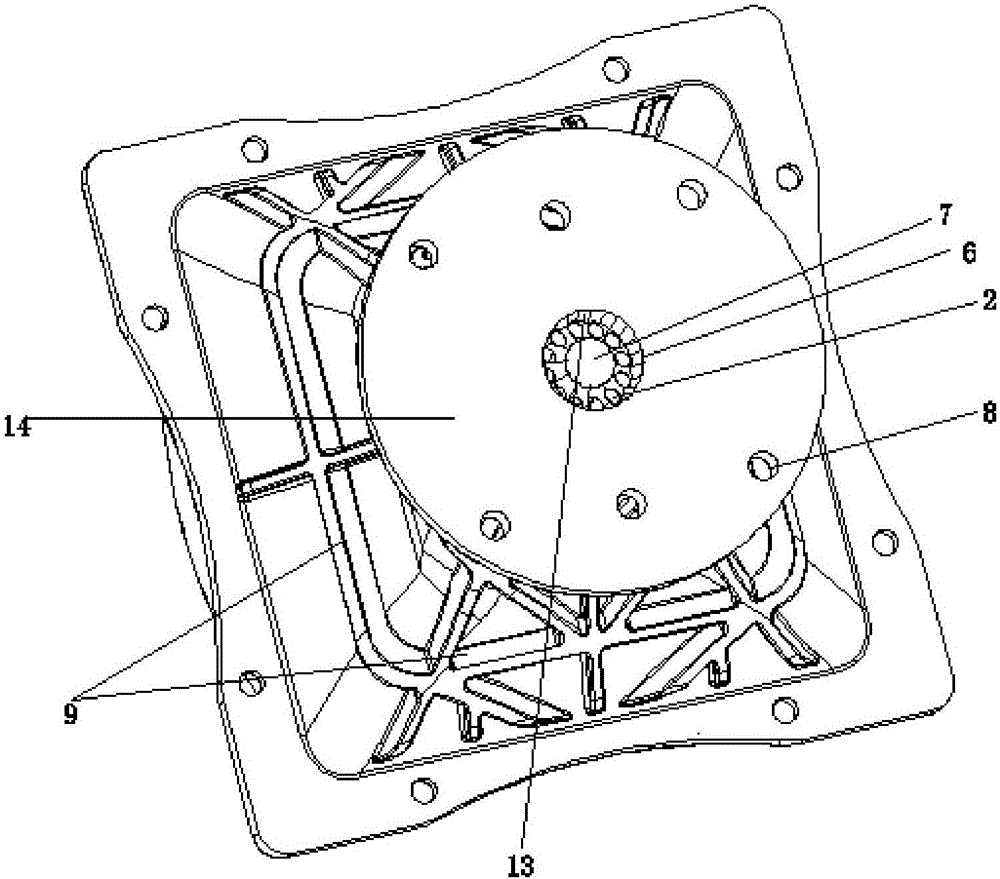

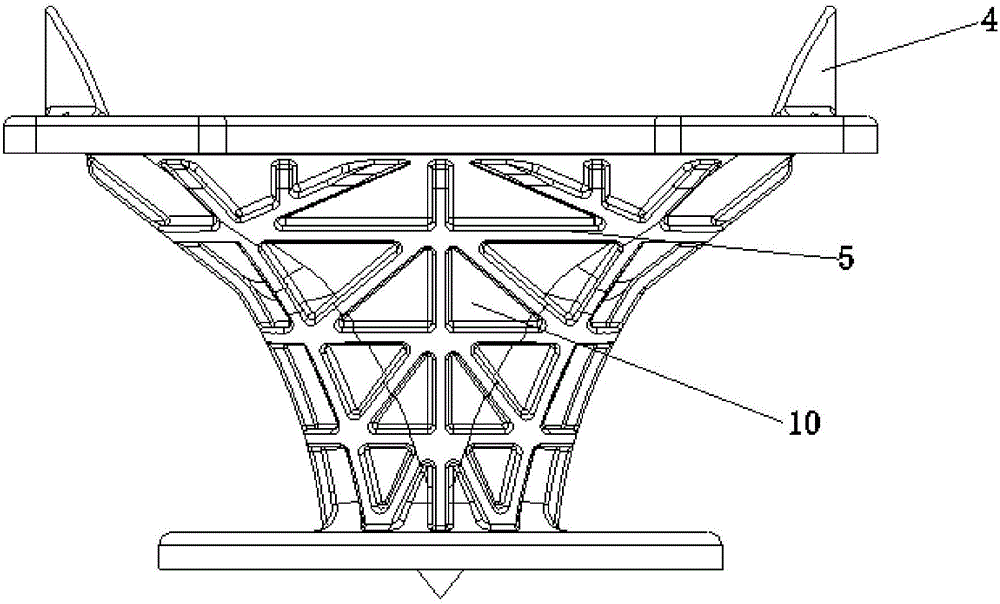

[0033] A loudspeaker horn, comprising a trumpet-shaped housing 10, the small end of the housing 10 is connected to the mounting base 14, and the large end is a face plate, and the housing 12 includes a throat 11 connected with the horn driver, and the throat 11 is Several manifolds 2 are fixedly arranged, and the manifolds 2 communicate with the two ports of the throat pipe 11 . By setting the manifold 2 in the present invention, the upper limit frequency of the horn can be greatly improved.

[0034] Preferably, the horn further includes a deflector 7 for splitting the sound waves of the loudspeaker high frequency driver 16 . The arrangement of the deflector 7 can shunt the sound generated by the high-frequency driver 16, so that no sound focusing phenomenon occurs. The loudspeaker high-frequency driver is connected to the mounting base and is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com