speaker horn

A loudspeaker and horn technology, applied in the field of loudspeaker horn, can solve the problem that the lower limit frequency of the horn connected to the high-frequency driver cannot meet the needs, avoid the phenomenon of off-axis frequency response peaks and valleys, prevent standing waves and crossover distortion, and reduce the horn. sound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

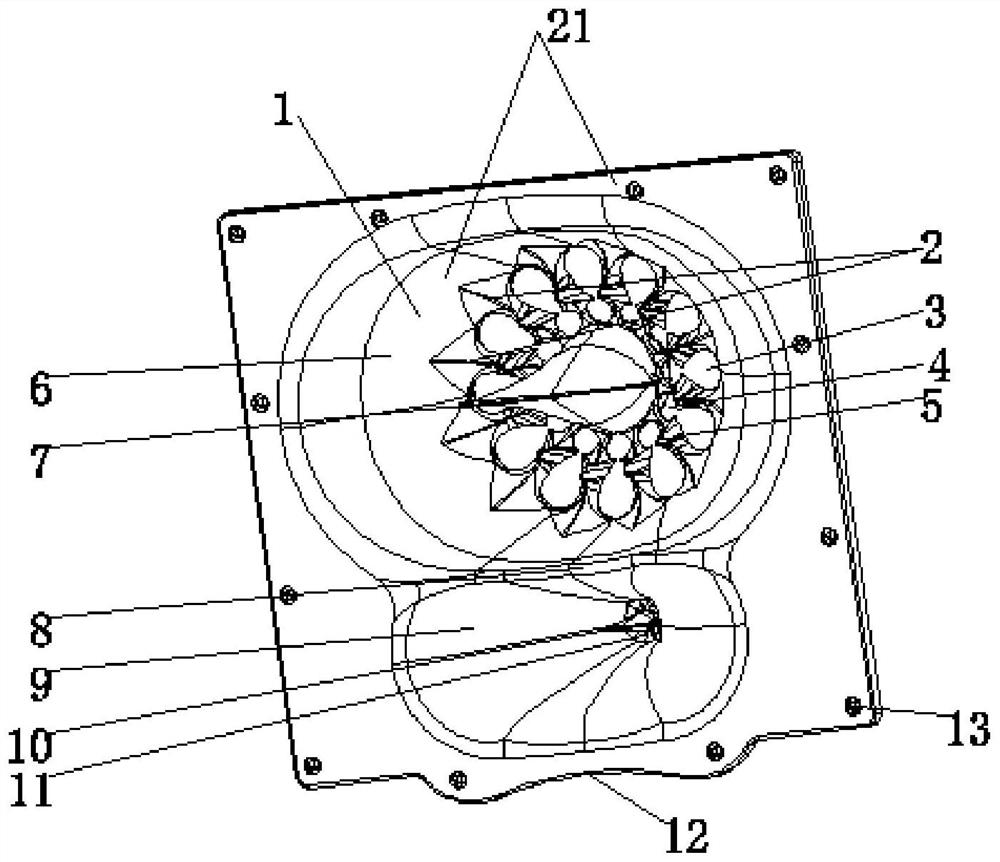

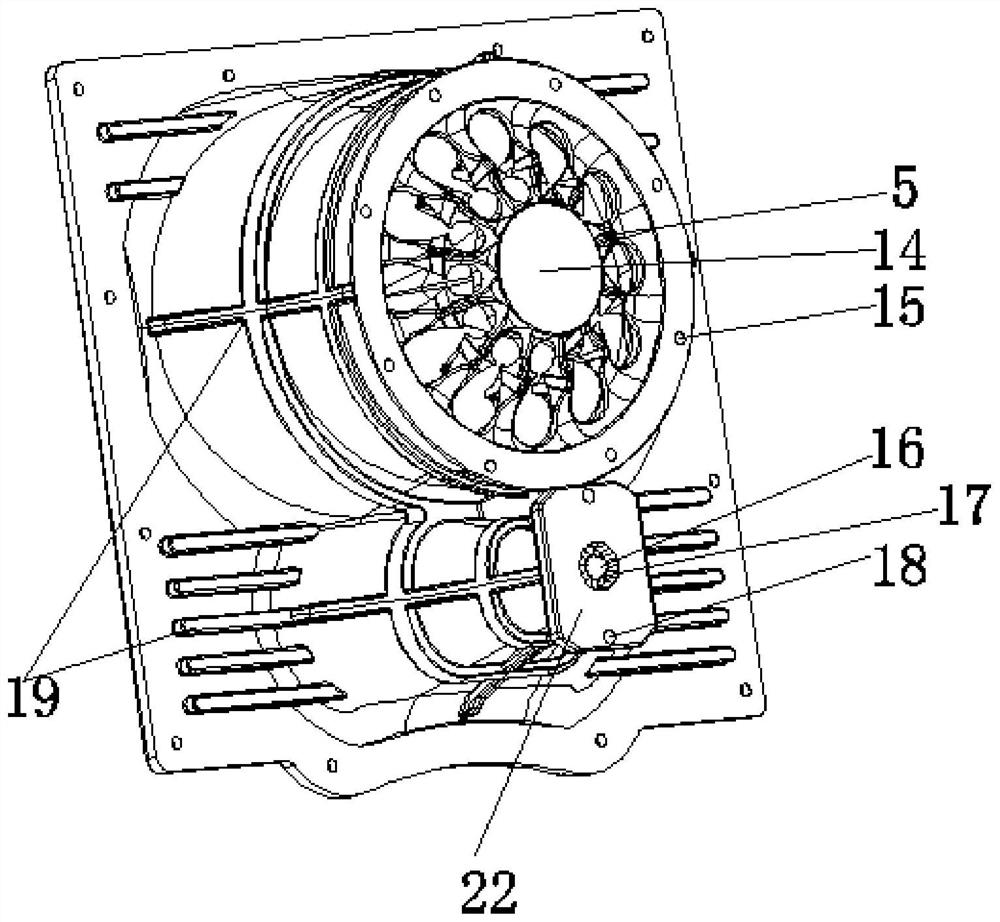

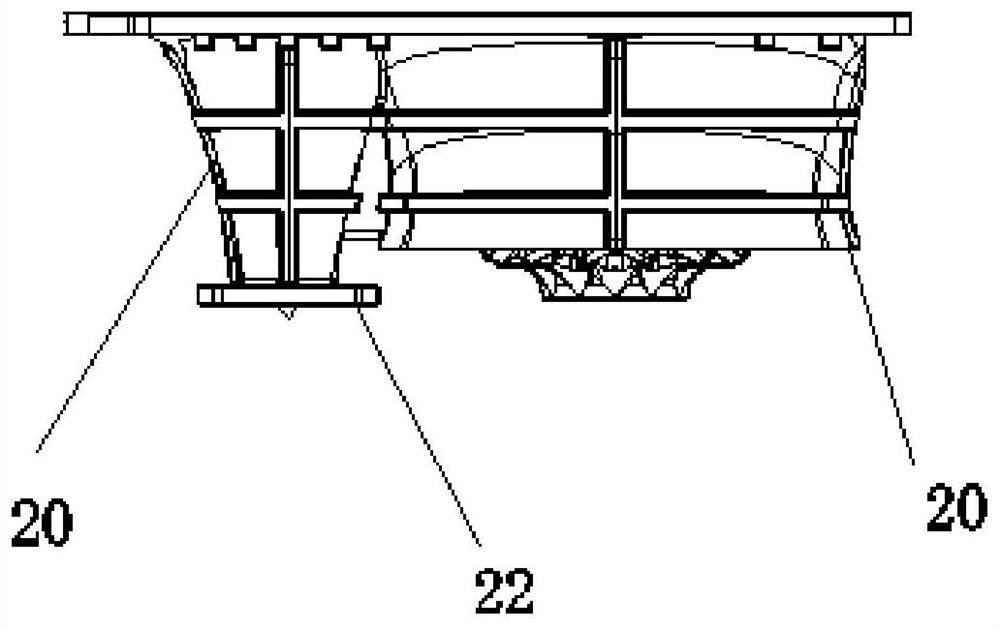

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0037] A loudspeaker horn, comprising at least two horn units connected to each other, each horn unit comprising a horn-shaped casing 20, the large end of the casing 20 is a face plate 21, and the casing 20 includes a throat pipe arranged at its small end, Several manifolds are fixed in the throat, and the manifolds communicate with the two ports of the throat. By setting the manifold, the present invention can greatly increase the upper limit frequency of the horn.

[0038] Preferably, there are two horn units, which are a high-frequency horn 9 and an intermediate-frequency horn 6 fixed on one side of the high-frequency horn 9 . The number of manifolds provided in the high frequency horn may be twelve, and the number of manifolds provided in the intermediate frequency horn may also be twelve. By setting up the manifold, the upper limit frequency o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com