Method for producing copper-free area between layers of printed board

A production method and copper-free area technology, applied in printed circuit manufacturing, printed circuit, multi-layer circuit manufacturing, etc., can solve the problems of process capacity reduction, unit cost increase, impedance, board thickness and other quality that cannot meet customer requirements, etc. Achieve the effect of reducing costs and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to more fully understand the technical content of the present invention, the technical solutions of the present invention are further introduced and described below with reference to specific embodiments, but are not limited thereto.

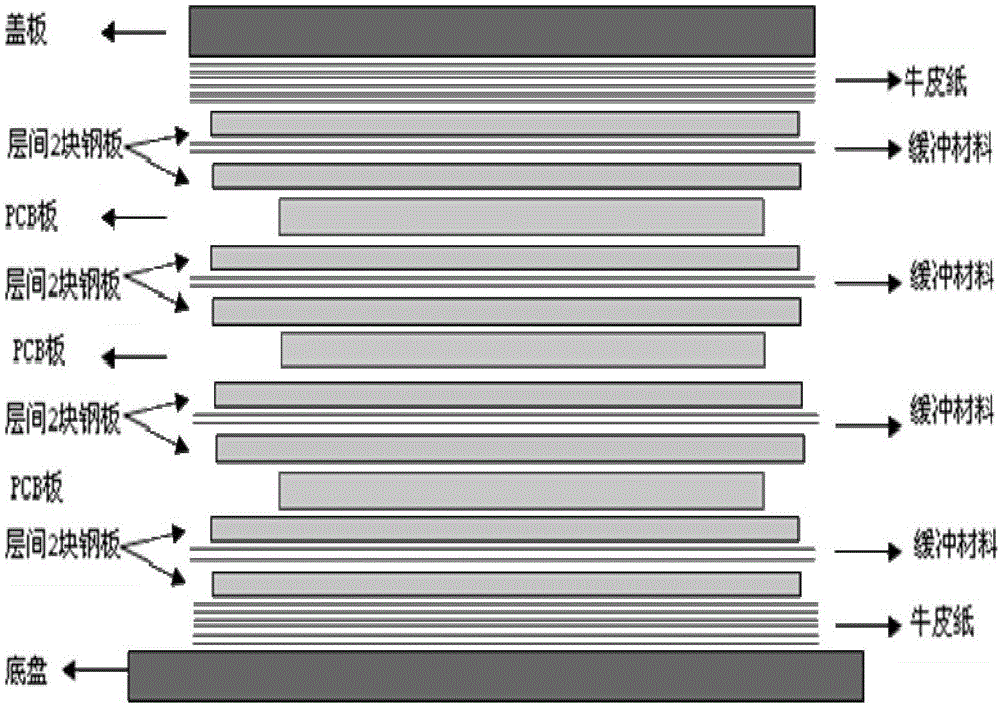

[0034] like Figure 2 to Figure 4 The specific embodiment shown, this embodiment provides a method for manufacturing a copper-free area between layers of a printed circuit board, which can be used in the manufacturing process of a printed circuit board to realize the design of opening the interlayer resin PP to fill Hollow hollow. Specifically, it can be used in the pressing process of various multi-layer boards, especially for the production of small batches of circuit boards and prototype circuit boards.

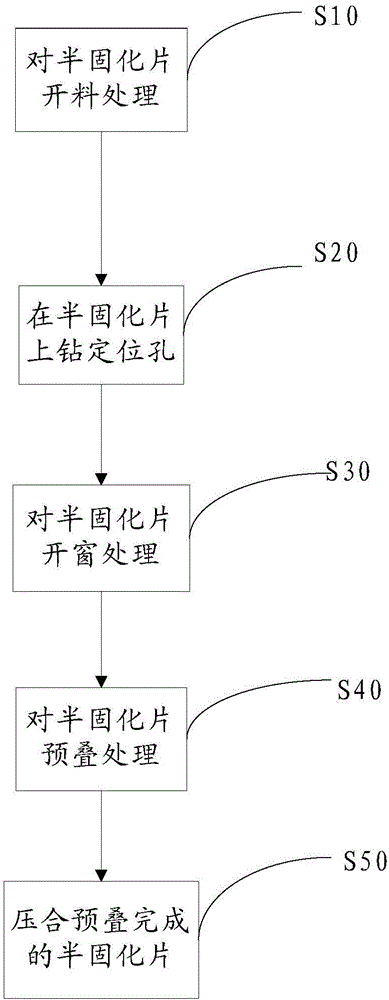

[0035] A method for manufacturing a copper-free area between layers of a printed board, comprising the following steps:

[0036] S10, open the prepreg;

[0037] S20, drilling positioning holes on the prepreg;

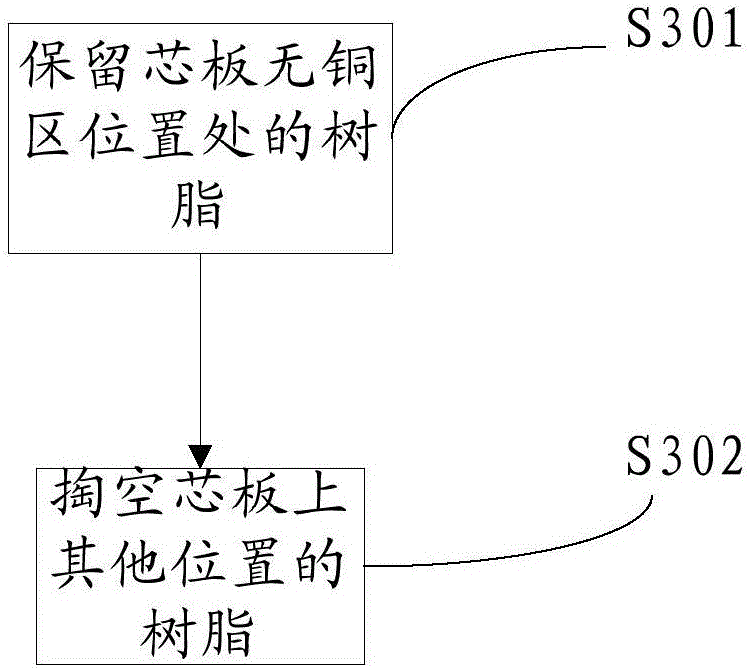

[0038] S30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com