e-cigarette

An electronic cigarette and electrode technology, which is applied in the field of electronic cigarettes, can solve the problems of high cost of replacing the atomizing core, inconvenient disassembly and assembly of the atomizing core, etc., and achieve the effects of low replacement cost, reduced loss time, and increased sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

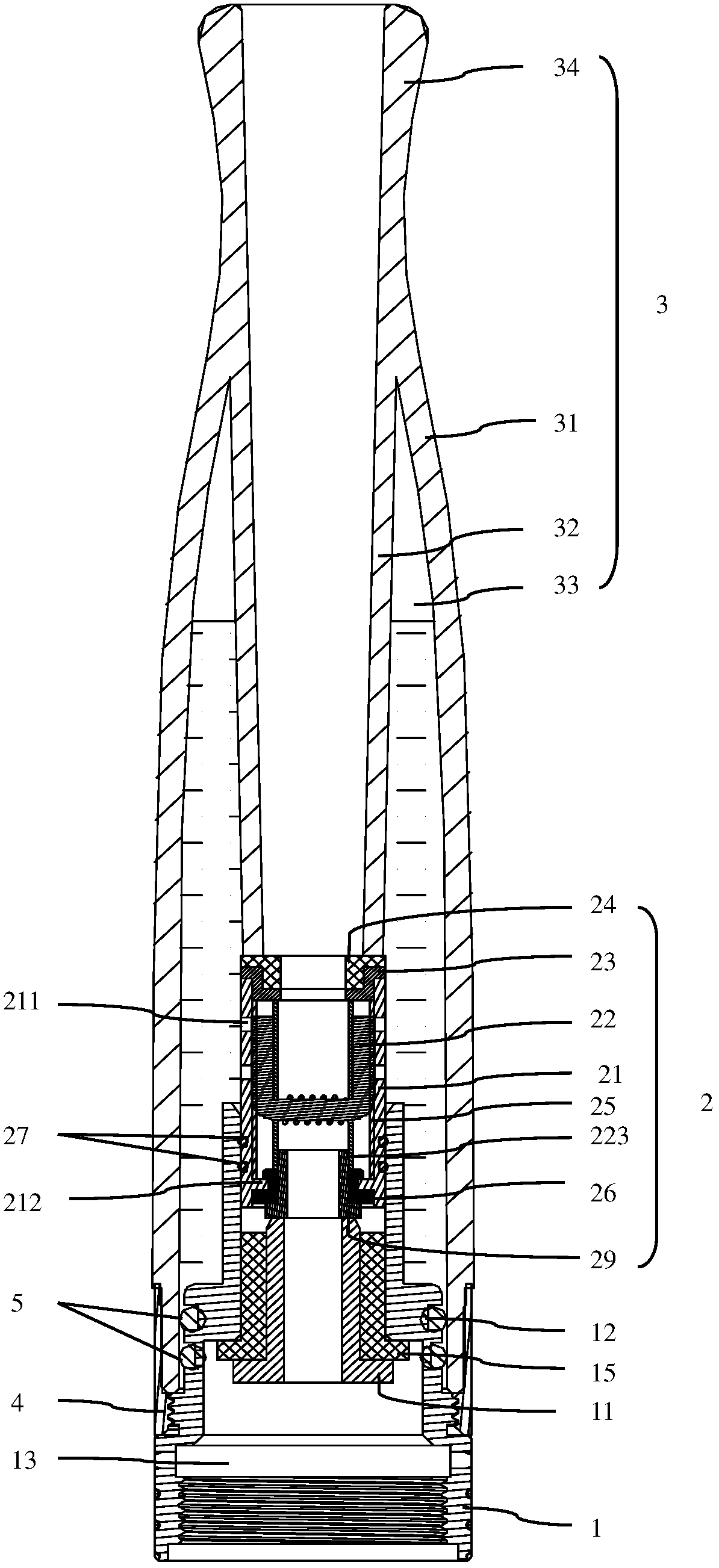

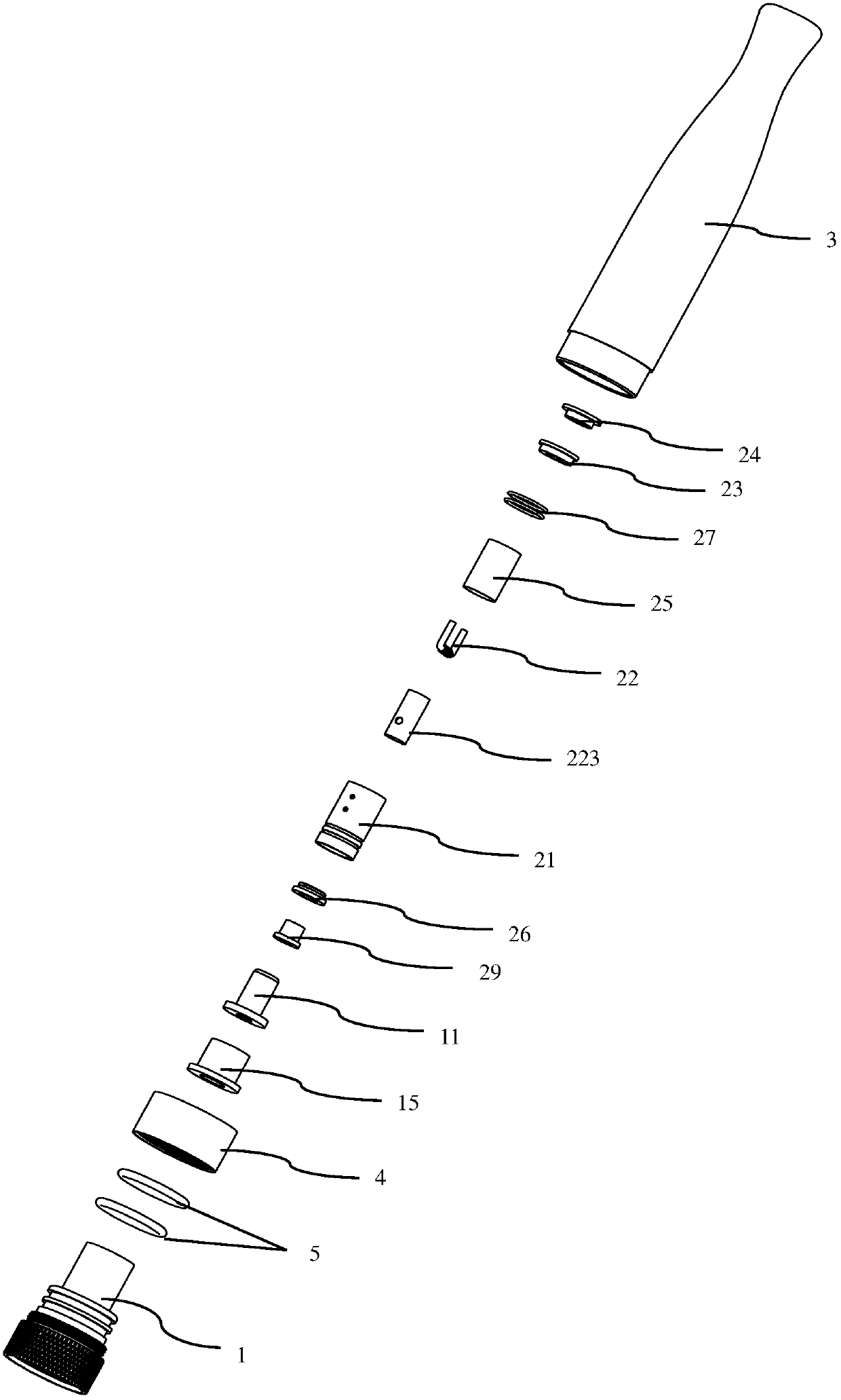

[0039] Example 1: Please refer to figure 1 , combined with figure 2 , image 3 with Figure 4 shown.

[0040] The atomization assembly in this embodiment includes a connection sleeve 1 , an atomization core 2 and an oil cup assembly 3 , and the connection sleeve 1 is detachably connected to the atomization core 2 , the oil cup assembly 3 and the battery assembly respectively.

[0041] The connecting sleeve 1 has a mounting through hole 13 that runs through itself, and the diameter of the mounting through hole 13 is stepped in the axial direction. The inner wall of one end of the mounting through hole 13 is provided with a threaded structure for detachable connection with the battery pack. A lower electrode 11 and a first insulating sleeve 15 are provided for abutting against electrodes in the battery assembly to realize electrical connection.

[0042] The connecting sleeve 1 is made of conductive material or is provided with a conductive layer on the surface, and can be dir...

Embodiment 2

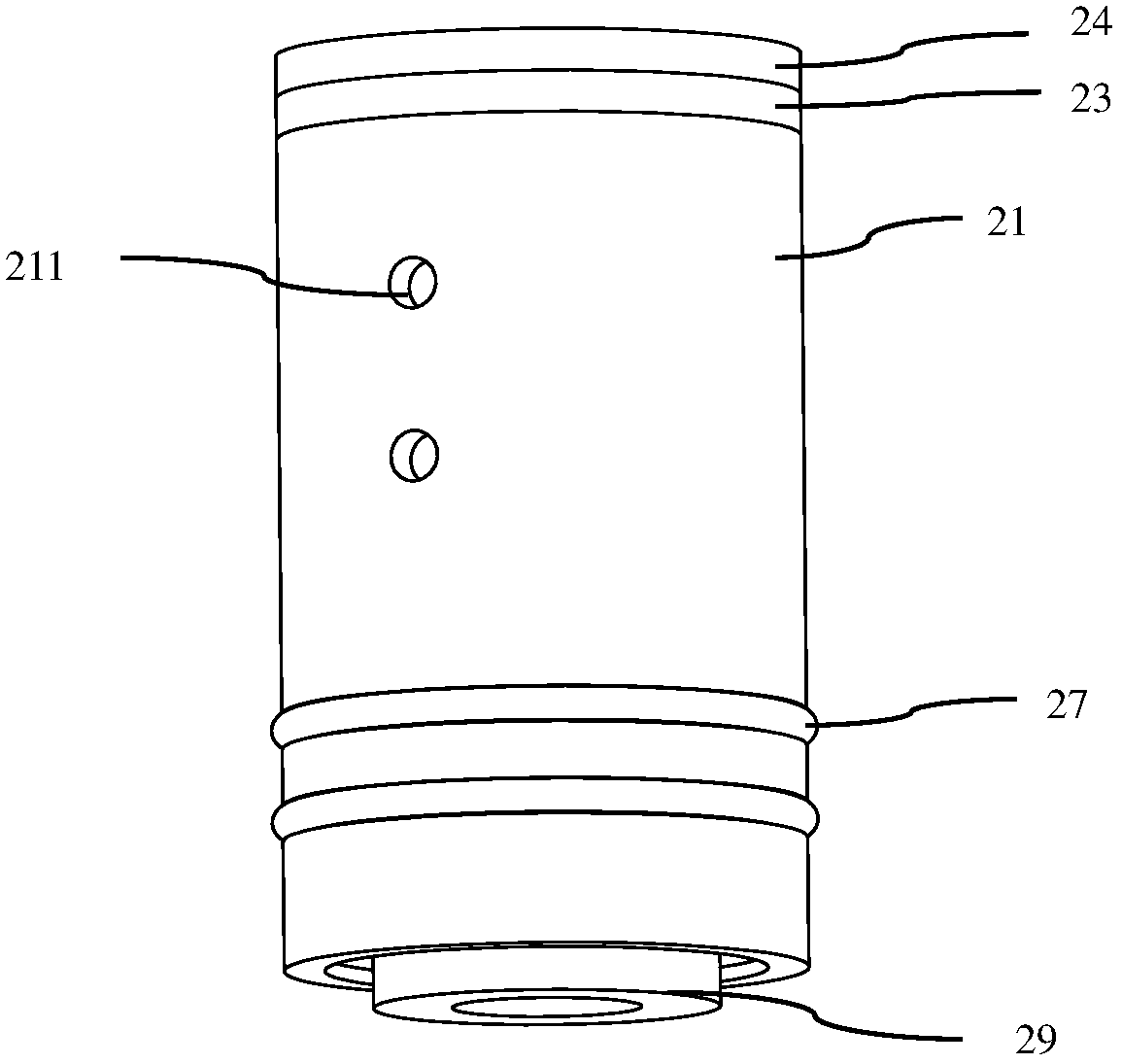

[0062] Example 2: Please refer to Figure 5 shown.

[0063] The difference between this embodiment and the first embodiment lies in the elastic contact between the lower electrode 11 and the inner electrode 29 to improve the electrical conductivity; in addition, the two ends of the atomizing core 2 are respectively elastically contacted with the oil cup assembly 3 and the lower electrode 11 , and is clamped and fixed by the oil cup assembly 3 and the lower electrode 11 , this elastic clamping and fixing method can play a buffering role and enhance the shock resistance of the atomizing core 2 .

[0064] Specifically, a guide sleeve 14 sleeved on the lower electrode 11 is also provided between the lower electrode 11 and the first insulating sleeve 15. The guide sleeve 14 has a guide through hole 141 and is accommodated in the guide through hole. Elastic member 142 in 141. The inner wall of the guide sleeve 14 protrudes inwardly at the end away from the atomizing core 2 to form...

Embodiment 3

[0068] Embodiment three please refer to Image 6 , combined with Figure 7 with Figure 8 shown.

[0069] The difference between this embodiment and Embodiments 1 and 2 is that the outer wall surface of the atomization sleeve 21 is provided with friction lines 213 on one end close to the oil cup assembly 3 or on the entire outer wall surface of the atomization sleeve 21 for use in When the user pulls out the atomizing core 2, the friction force between the atomizing core 2 and the human hand is enhanced, further facilitating disassembly and assembly of the atomizing core 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com