Telescopable spring support

A technology for supporting devices, pressure springs, applied in the direction of springs, springs/shock absorbers, coil springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

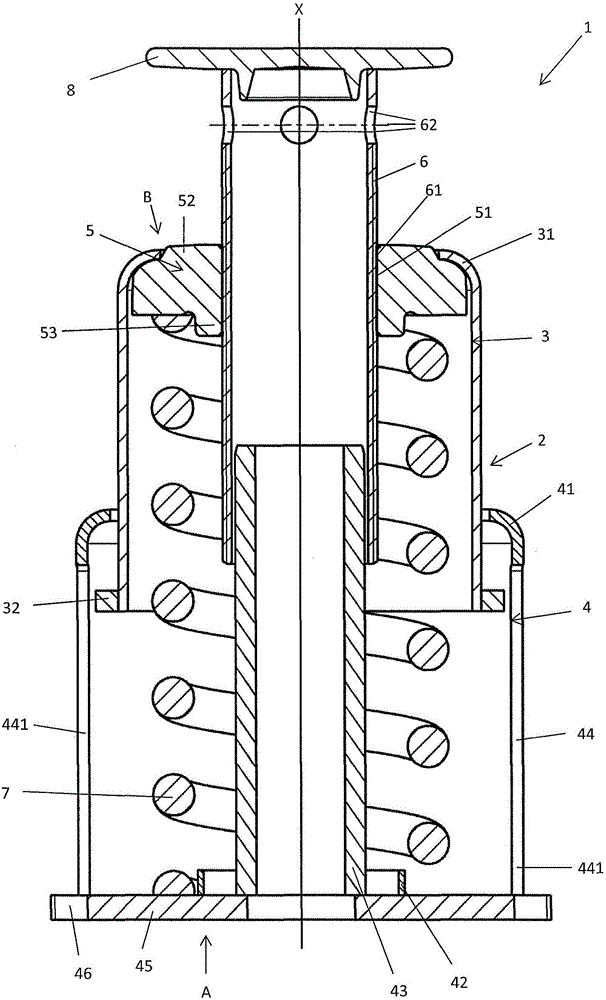

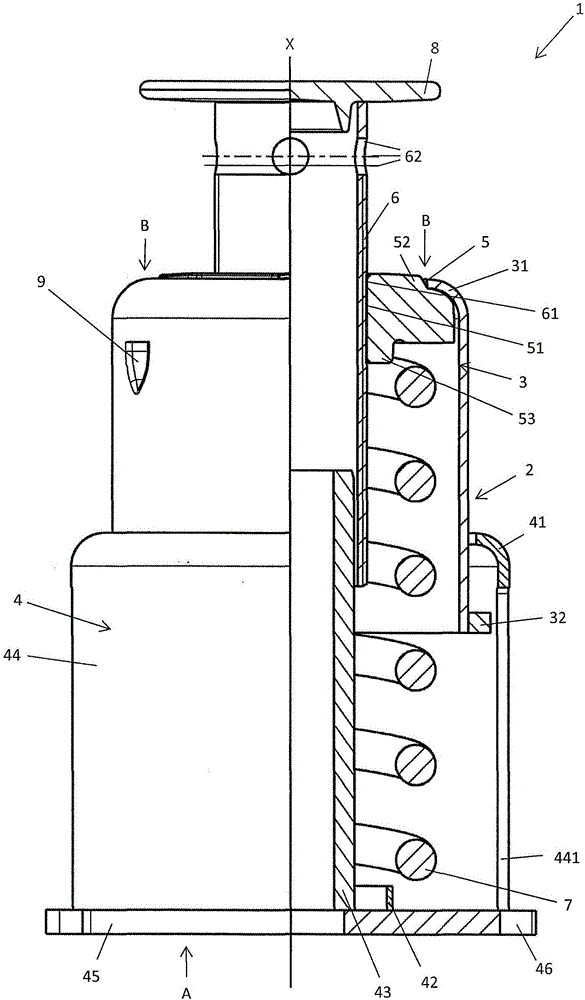

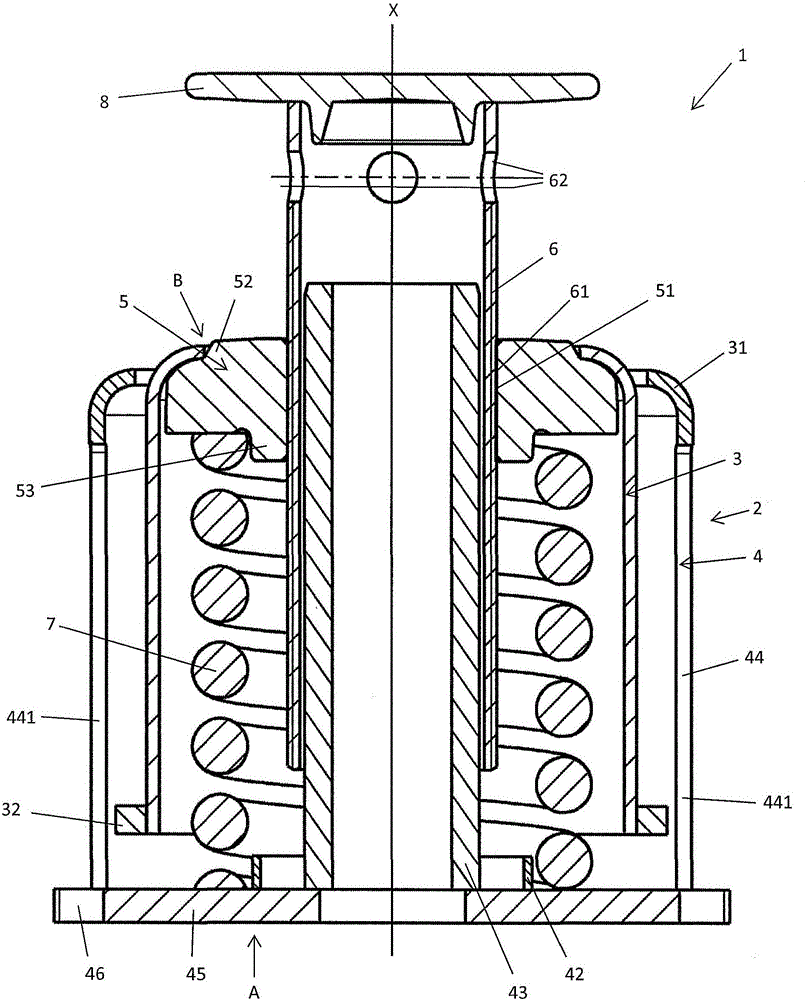

[0034] Figure 1a A schematic sectional view of an embodiment of a spring support device 1 according to the invention is shown. The spring support device 1 comprises a housing 2 consisting of a stationary housing 4 and a movable housing 3 . The resulting two-part construction of the housing 2 can be overall advantageous and particularly simple. The stationary housing is formed in the form of a hollow cylinder. The support side A of the spring support device 1 is arranged on the stationary housing 4 , wherein the spring support device 1 is placed by means of the support side A in its operating position. The stationary housing 4 comprises a base plate 45 provided with holes 46 so that the base plate 45 can be rigidly screwed to ground. The first fixing protrusion 42, the cylindrical guide 43 and the tubular section 44 are welded to the base plate. The tubular section 44 is formed in the manner of a hollow cylinder and has an outer diameter of approximately 200 mm. At its end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com