Sleeve-fish sucker-removing device

A suction cup and squid technology, which is applied in the processing and slaughtering of fish and cephalopods, can solve the problems of waste, incomplete peeling and long time consumption, and achieve the effect of reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

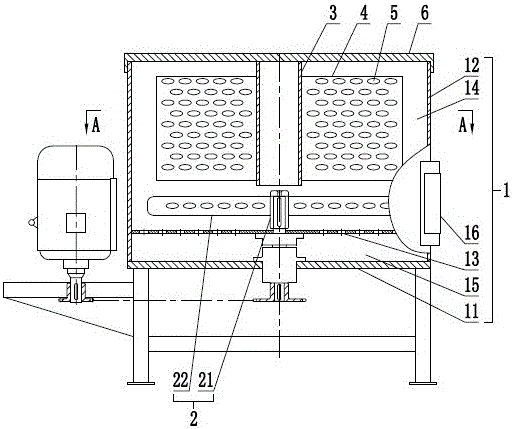

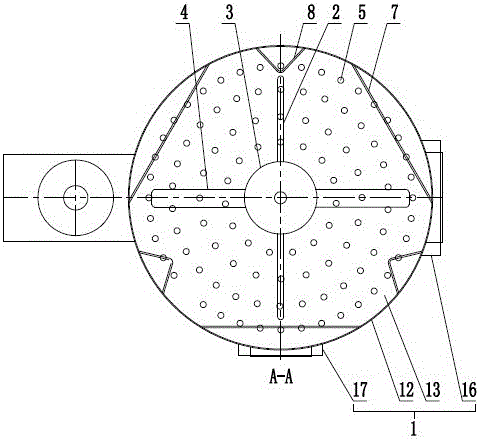

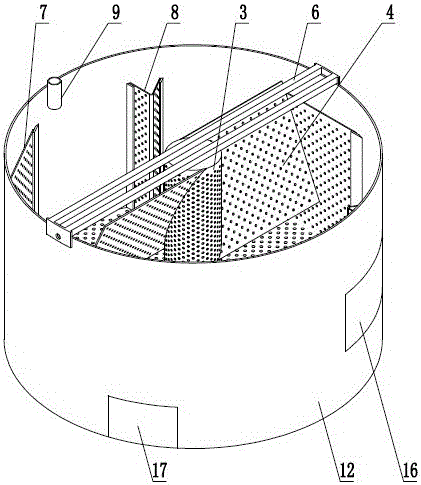

[0025] In the example, such as figure 1 , figure 2 , image 3 Shown, a kind of squid takes off sucker device, comprises tank body 1, and described tank body 1 establishes bottom plate 11 and sidewall 12, and described tank body 1 is equipped with and is used to make material circumferential rotation and the stirring device 2 that rolls up and down, so The main scraper 4 is set in the tank body 1, and the main scraper 4 is installed obliquely and the lower end faces the flow direction of the squid to be processed; the main scraper 4 is densely covered with some sieve holes 5, and the diameter of the sieve holes 5 is larger than The diameter of the suction cup of the squid to be processed; a gap is provided between the main scraper 4 and the bottom plate 11, and the gap constitutes a flow channel of the squid to be processed. The squid and water to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com