Bridging locking plate

A locking plate and bridging technology, applied in the field of medical devices, can solve the problem of not considering stress and bending stiffness, and achieve the effect of ensuring safety and effectiveness, increasing bending stiffness and equivalent bending strength, and reducing the probability of fracture of bone plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

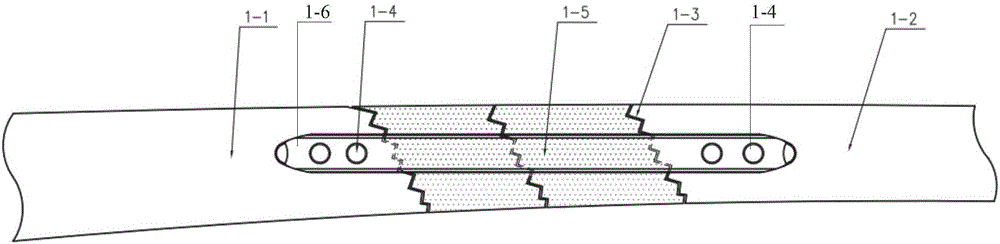

Embodiment 1

[0028] Please refer to figure 1 , This embodiment provides a bridge locking plate, including a plate body 1-6 and a plurality of locking holes 1-4 arranged on the plate body 1-6, the plurality of locking holes 1-4 along the plate body 1-6 The longitudinal direction is distributed on both sides of the fracture line 1-3 to form a bridge structure; among them, the bridge structure is a single bridge type. Specifically, such as figure 1 As shown, there are two locking holes 1-4 on each of the longitudinal ends of the plate body 1-6. The plate body between the locking holes at both ends spans the fracture area 1-5, like a bridge, connecting the normal bones at both ends Part 1-1, 1-2. Generally, the locking plate in this embodiment is used to treat comminuted fractures or shaft fractures with multiple fractures and thick surrounding muscles. Because of the partial loss of the original mechanical strength of this type of fracture, it is difficult to use screws to fix the plate throu...

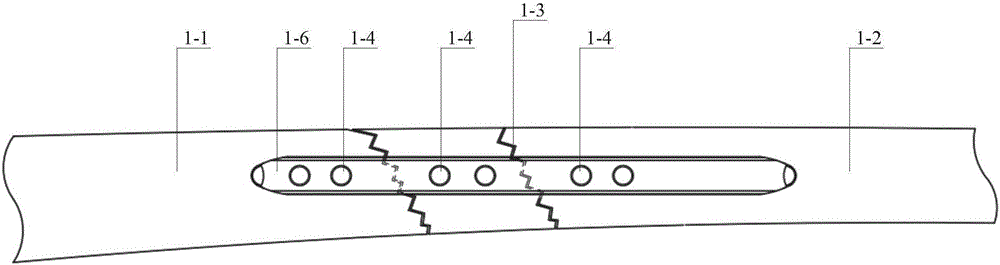

Embodiment 2

[0032] Please refer to Figure 2 to Figure 3 , The bridge locking plate provided in this embodiment has a double bridge type of bridge structure; specifically, it is provided with multiple or more groups of locking holes 1-4 in the longitudinal direction of the plate body 1-6, multiple or more groups The locking holes 1-4 are distributed on the longitudinal ends of the plate body 1-6 and the middle part of the plate body 1-6, and there is a fracture between the locking hole at each of the longitudinal ends and the locking hole in the middle part respectively. Line 1-3. Such as figure 2 As shown, the longitudinal ends of the plate body 1-6 are respectively provided with two locking holes 1-4, the middle part of the plate body 1-6 is provided with two locking holes 1-4, each of the longitudinal ends is locked There is a fracture line 1-3 between the hole and the locking hole of the middle part respectively. Of course, the number of locking holes in the middle part can also be d...

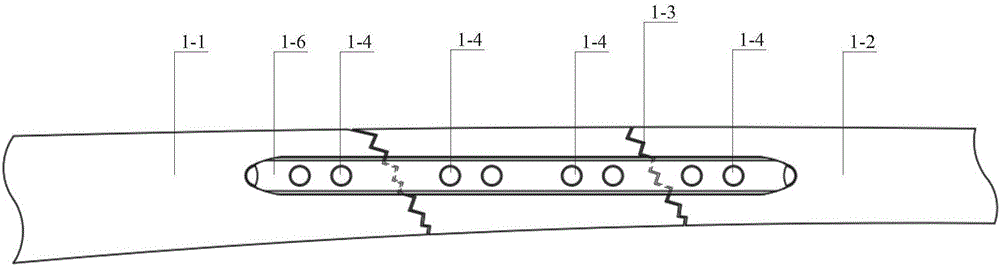

Embodiment 3

[0036] Please refer to Figure 4 , The bridge locking plate provided by this embodiment has a multi-bridge type of bridge structure; specifically, two locking holes 1-4 are provided at both longitudinal ends of the plate body 1-6, and the middle part of the plate body 1-6 is provided There are two locking holes 1-4, a fracture line 1-3 is corresponding between the two locking holes in the middle part, and the locking hole at each end of the longitudinal ends corresponds to the locking hole in the middle part near the end There is 1 fracture line 1-3.

[0037] Generally, the fractures that the locking plate is used to treat are between comminuted fractures and transverse fractures. Because of the mechanical strength of this kind of fracture block, the mechanical strength is higher than the strength of comminuted fracture, and the size is not enough to accommodate more than two screws. Therefore, the locking hole in the middle part of the plate is a single locking hole.

[0038] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com