Modification and modification method of ceramic membrane and modified ceramic membrane

A technology for modification and modification of ceramic membranes, applied in the field of modification and modification of ceramic membranes and modified ceramic membranes, can solve the problems of poor stability of organic polymer membranes, and achieve good long-term stability and service life, good stability and performance. The effect of improving hydrophobicity and self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

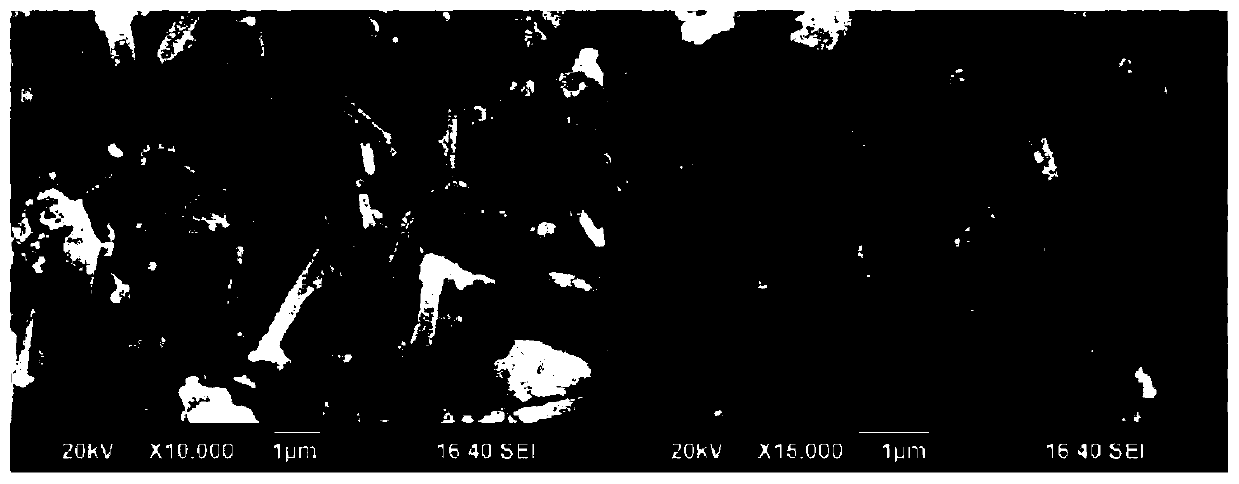

[0063] This embodiment provides a method for modifying a ceramic membrane, which includes the following steps:

[0064] Step 1: Surface-treat the silicon nitride ceramic membrane. The treatment method is: put the silicon nitride ceramic membrane into a 5mol / L sodium hydroxide solution and boil for 30 minutes. After taking it out, wash it with pure water and dry it to obtain fresh nitrogen. Silicon ceramic membrane;

[0065] Step 2, add 2.5g of methyldichlorosilane and 2.5g of dimethyldichlorosilane into 10mL of n-heptane, stir well to obtain solution A; soak the above-mentioned fresh silicon nitride ceramic membrane in solution A , take out and dry;

[0066] Step 3, transfer the ceramic film coated in step 2 to a boron nitride porcelain boat, place the boron nitride porcelain boat in the quartz chamber of the resistance wire furnace, and carry out slow ammonia gas purging (the ammonia gas speed is 100mL / min), until the surface of the ceramic membrane is completely covered b...

Embodiment 2

[0074] This embodiment provides a method for modifying a ceramic membrane, which includes the following steps:

[0075] Step 1: Surface-treat the silicon nitride ceramic membrane. The treatment method is: put the silicon nitride ceramic membrane into a 10mol / L potassium hydroxide solution and boil for 1 hour. After taking it out, wash it with pure water and dry it to obtain fresh nitrogen. Silicon ceramic membrane;

[0076] Step 2, add 2.5g of methyldichlorosilane and 2.5g of dimethyldichlorosilane into 10mL of ethanol, stir evenly to obtain solution A; soak the above-mentioned fresh silicon nitride ceramic membrane in solution A, take out dry;

[0077] Step 3, transfer the ceramic film coated in step 2 to a boron nitride porcelain boat, place the boron nitride porcelain boat in the quartz chamber of the resistance wire furnace, and carry out slow ammonia gas purging (the ammonia gas speed is 100mL / min), until the surface of the ceramic membrane is completely covered by the...

Embodiment 3

[0084] This embodiment provides a method for modifying a ceramic membrane, which includes the following steps:

[0085] Step 1: Surface-treat the silicon nitride ceramic membrane. The treatment method is: put the silicon nitride ceramic membrane into a saturated calcium hydroxide solution and boil for 30 minutes. After taking it out, wash it with pure water and dry it to obtain fresh silicon nitride Ceramic Membrane;

[0086] Step 2: Add 5g of methyldichlorosilane and 5g of dimethyldichlorosilane into 10mL of ethanol, stir evenly to obtain solution A; soak the above-mentioned fresh silicon nitride ceramic membrane in solution A, take out and dry;

[0087] Step 3, transfer the ceramic film coated in step 2 to a boron nitride porcelain boat, place the boron nitride porcelain boat in the quartz chamber of the resistance wire furnace, and carry out slow ammonia gas purging (the ammonia gas speed is 100mL / min), until the surface of the ceramic membrane is completely covered by so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com