Hydrophobic modified fluorescent powder, and preparation method and application thereof

A hydrophobic modification, phosphor technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of affecting the service life, luminescence attenuation of fluorescent materials, affecting the luminescence of fluorescent materials, etc., to achieve good long-term stability, Good long-term stability and service life, and the effect of improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This example provides a hydrophobically modified Ba 2 SiO 4 :Eu 2+ Green fluorescent powder, which is prepared by the following steps:

[0065] Weigh 1g Ba 2 SiO 4 :Eu 2+ For green fluorescent powder, place the fluorescent powder in ammonia solution for 10 minutes, then wash and dry;

[0066] Ba after ammonia treatment 2 SiO 4 :Eu 2+ Green fluorescent powder was added to 25mL of n-heptane to form a mixed solution, and 5mL of methyldichlorosilane and 5ml of dimethyldichlorosilane were added to the above mixed solution, stirred for 30 minutes, and the n-heptane was completely volatilized to obtain a mixture sample;

[0067] Put the mixture sample in a horizontal tube furnace with ammonia gas for 5 minutes, then pyrolyze it at 500°C for 2 hours, then cool it to obtain a mixture of residual liquid polysiloxane, filter the mixture, and dry it. Hydrophobically modified Ba 2 SiO 4 :Eu 2+ Green phosphor.

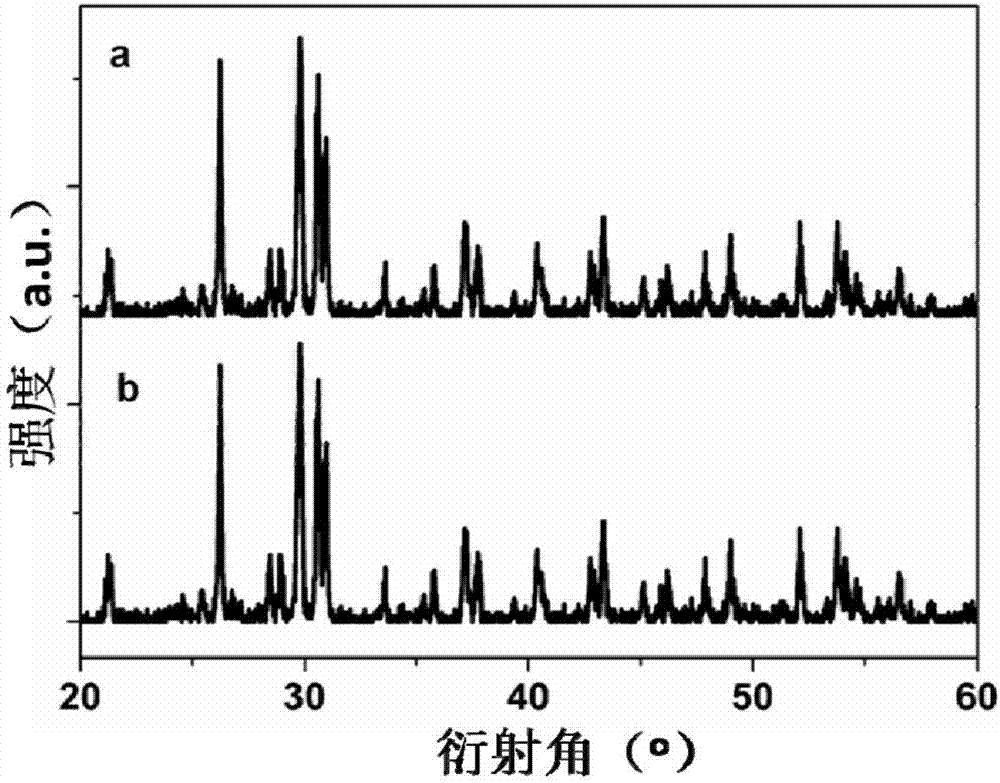

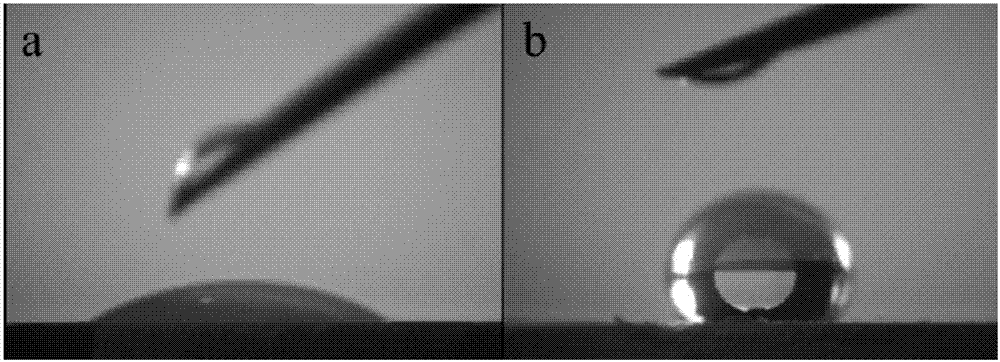

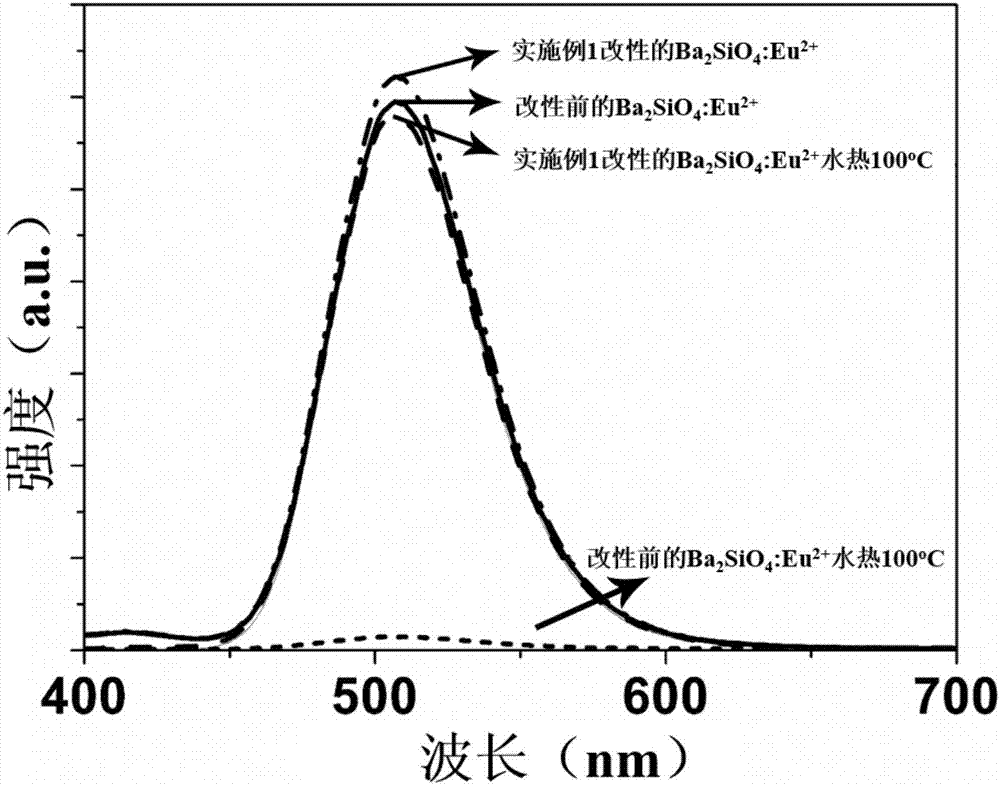

[0068] Ba before and after the hydrophobic modification of th...

Embodiment 2

[0073] This example provides a hydrophobically modified Ca 2 Si 5 N 8 :Eu 2+ Red fluorescent powder, it is prepared by the following steps:

[0074] Weigh 1g Ca 2 Si 5 N 8 :Eu 2+ For red fluorescent powder, place the fluorescent powder in aqueous oxalic acid solution for 15 minutes, then wash and dry;

[0075] Ca after treatment with oxalic acid aqueous solution 2 Si 5 N 8 :Eu 2+ Add red fluorescent powder to 15mL cyclohexane to form a mixed solution, add 5mL methyldichlorosilane to the above mixed solution, stir for 30 minutes, the cyclohexane is completely volatilized, and a mixture sample is obtained;

[0076] Put the mixture sample in a horizontal tube furnace with ammonia gas for 5 minutes, then pyrolyze it at 500°C for 2 hours, then cool it to obtain a mixture of residual liquid polysiloxane, filter the mixture, and dry it. Hydrophobically modified Ca 2 Si 5 N 8 :Eu 2+ red phosphor.

[0077] The Ca after hydrophobic modification of this embodiment 2 Si ...

Embodiment 3

[0082] This example provides a hydrophobically modified Ba 2 Si 5 N 8 :Eu 2+ Red fluorescent powder, it is prepared by the following steps:

[0083] Weigh 1g Ba 2 Si 5 N 8 :Eu 2+ Red fluorescent powder, placed in ammonia solution for 15 minutes, then washed and dried;

[0084] Ba after ammonia treatment 2 Si 5 N 8 :Eu 2+ Add red fluorescent powder to 25mL benzene to form a mixed solution, add 3mL methyldichlorosilane and 3ml dimethyldichlorosilane to the above mixed solution, stir for 30 minutes, the benzene is completely volatilized, and a mixture sample is obtained;

[0085] Put the mixture sample in a horizontal tube furnace with ammonia gas for 5 minutes, then pyrolyze it at 400°C for 2 hours, then cool it to obtain a mixture of residual liquid polysiloxane, filter the mixture, and dry it. Hydrophobically modified Ba 2 Si 5 N 8 :Eu 2+ red phosphor.

[0086] Ba after hydrophobic modification of the present embodiment 2 Si 5 N 8 :Eu 2+ X-ray diffraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com