Method for cultivating plant by using LED (light-emitting diode) light source and device for method

A technology of LED light source and cultivation device, applied in the field of general botany, can solve the problem of far from meeting the requirements of energy saving, and achieve the effect of reducing the luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

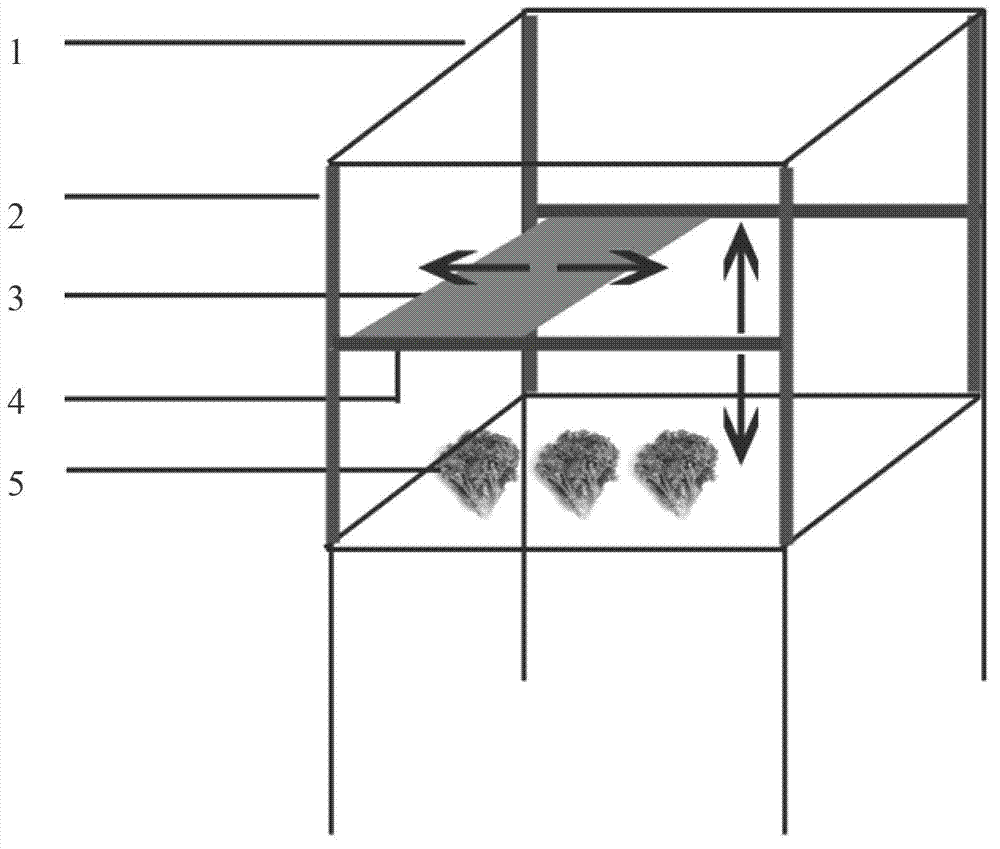

[0022] Treatment group: eg figure 1 , a device for cultivating plants, comprising an LED light source board 3, a plant 5, a cultivation tank for placing the plant 5, and a cultivation frame 1 for the LED light source board 3, the LED light source board 3 is located above the plant 5, and the vertical support of the cultivation frame is installed with Vertical guide rail 2, horizontal guide rail is installed on the horizontal support. The LED light source board 3 is kept at a certain height above the plant 5 by the traction of the motor, and moves upward when the plant 5 grows tall. In this embodiment, the control LED light source board is located 5 cm above the plants. The same area of plants was irradiated with the same area of light board (light source board) as that of the control group. The device is placed in a plant factory, placed in multiple layers.

[0023] Control group: the light source board with the same area as the plant cultivation area was fixed at 25cm ...

Embodiment 2

[0027] Treatment group: eg figure 1 , a device for cultivating plants, comprising an LED light source board 3, a plant 5, a cultivation tank for placing the plant 5, and a cultivation frame 1 for the light source board, the light source board 3 is located above the plant 5, and a vertical guide rail 2 is installed on the vertical support of the cultivation frame , the horizontal guide rail is installed on the horizontal support. The LED light source board 3 per unit area is located 15 cm above the plant 5. It moves horizontally once every 10 hours and turns off, and then turns on the lighting again after 2 hours. The moving distance is the length of one LED light source board 3, so that it can illuminate the 2 plants below in turn. Plants 5 times the area of the light source board. The device is placed in a plant factory, placed in multiple layers.

[0028] Control group: the light source panel with the same area as the plant cultivation area was fixed at 15cm above the pl...

Embodiment 3

[0032] Treatment group: eg figure 1 , a device for cultivating plants, comprising an LED light source board 3, a plant 5, a cultivation frame 1 for placing the plants and the light source board, the LED light source board 3 is located above the plant 5, a vertical guide rail 2 is installed on the vertical support of the cultivation frame, and a horizontal support Horizontal guide rails are installed on it. The LED light source board 3 is kept at a certain height above the plant 5 by the traction of the motor, and moves upward when the plant grows taller. In this embodiment, the control light source board is located 5 cm above the plants. At the same time, the light source board moves horizontally once every 10 hours and turns off, and turns on the lighting again after 2 hours. The moving distance is the length of an LED light source board, so that it turns to illuminate the plants below twice the area of the light source board. The device is placed in a plant factory, plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com