Near infrared fluorescence temperature sensing method and material

A sensing method, fluorescent temperature technology, applied in the field of temperature sensing, can solve the problems of limited detection depth and application, and achieve the effect of excellent detection accuracy and excellent detection depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

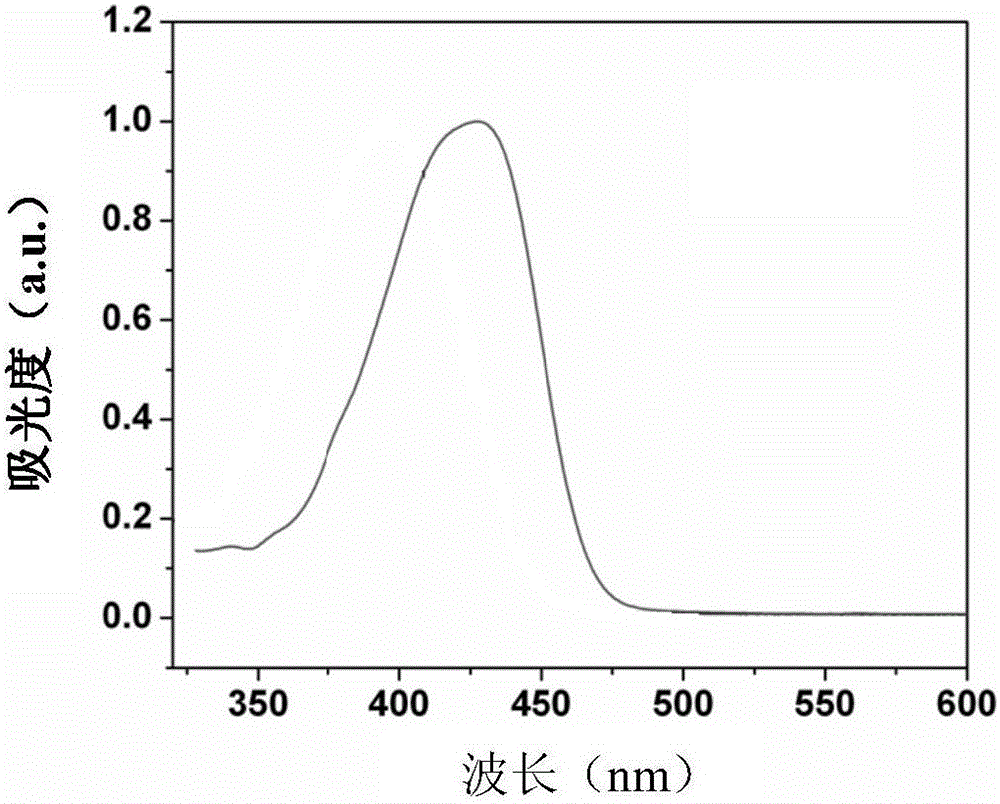

[0065] Embodiment 1, synthetic photosensitive ligand DFQZ (in the formula I, R 1 , R 2 is ethyl; R 3 , R 4 is butyl; R 5 =R 6 =R 7 =R 8 = methyl)

[0066] In the present embodiment, the DFQZ synthetic route, experimental conditions and each step yield are as follows:

[0067]

[0068] The specific operation steps are as follows:

[0069] 1) Synthesis of 2-(N,N-diethyl)-7-bromofluorene (compound 2)

[0070] In a 100ml round bottom flask, 2-amino-7-bromofluorene (compound 1) (1.0g, 3.8mmol) was dissolved in 60ml of glacial acetic acid. Place the reaction solution in an ice-water bath, slowly add 1.6g NaBH 4 (42.7mmol), heating makes the reaction solution rise to room temperature, then slowly adds 1.6gNaBH 4 , heating the reaction solution to 85° C. and maintaining it for 40 minutes. After the reaction was complete, it was cooled to room temperature, and NaOH aqueous solution was added to make the system neutral. The product was extracted three times with dichloro...

Embodiment 2

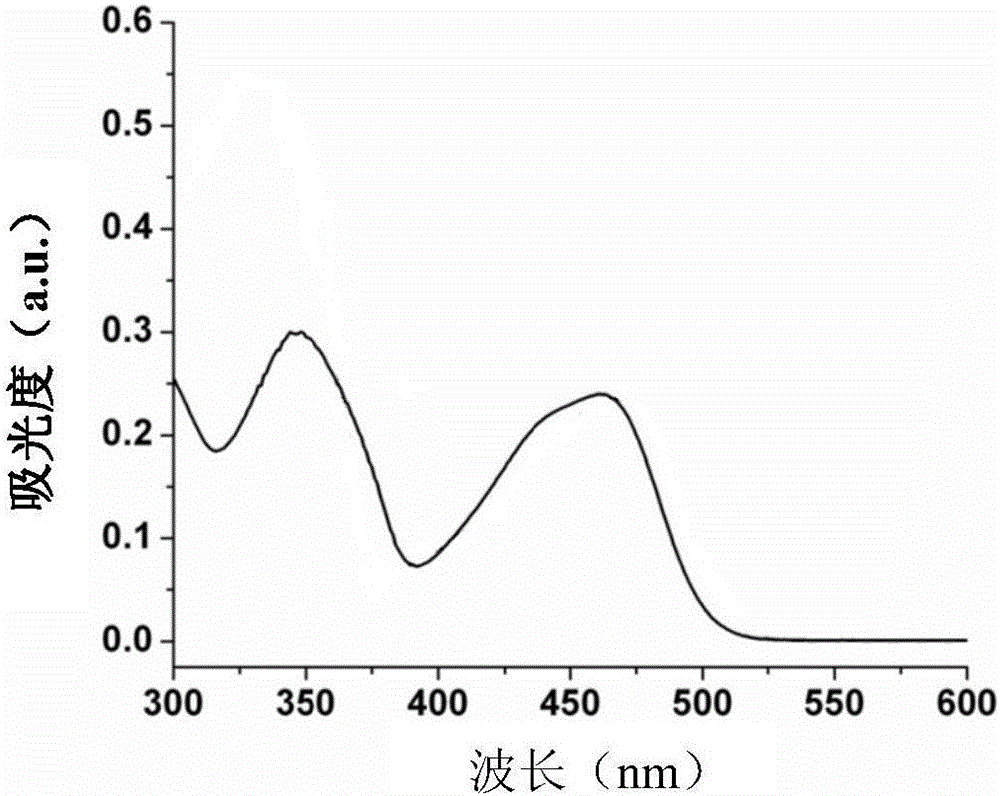

[0078] Embodiment 2, synthetic photosensitive complex Yb (tta) 3 · DFQZ (in formula III, R 1 , R 2 is ethyl; R 3 , R 4 is butyl; R 5 = R 6 = R 7 = R 8 = methyl)

[0079] Under stirring conditions, Yb(NO 3 ) 3 ·xH 2 O (470.0mg, 1.0mmol) ethanol solution (15mL) was added dropwise to HTTA (666.6mg, 3.0mmol) ethanol solution (15mL), and stirring was continued at room temperature, while ammonia water was added dropwise to adjust the pH value of the solution to neutral. After heating the reaction at 80-85° C. for 3 h, it was cooled to room temperature. Spin to dry ethanol to obtain a light yellow solid, wash the solid repeatedly with water, add benzene to dissolve the solid, and use anhydrous CaCl 2 dry. After filtering off the desiccant, distill off the solvent under reduced pressure to obtain a light yellow oil, add petroleum ether, heat, filter out the insoluble matter, distill off the petroleum ether under reduced pressure, and dry under vacuum to obtain the produc...

Embodiment 3

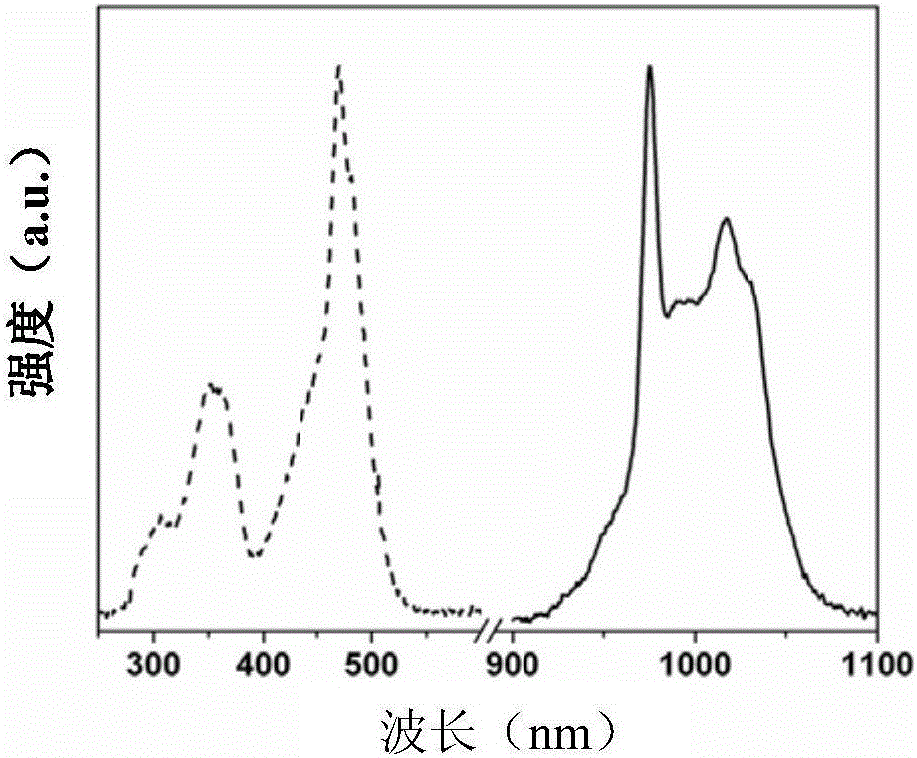

[0084] Embodiment 3, preparation is based on PMMA-Yb (tta) 3 · DFQZ temperature sensor

[0085] 1 mg Yb(tta) was mixed with stirring 3 DFQZ was dissolved in 10 mL of acetone solution containing 9 mg of polymethyl methacrylate (PMMA), and then the resulting mixed solution was dropped onto a 1.2 cm × 1.7 cm × 0.1 cm quartz plate, and dried in vacuum at 40 ° C for 12 hours to remove the solvent and form PMMA-Yb(tta) with a thickness of about 2.1 μm 3 ·DFQZ fluorescent temperature sensing film.

[0086] Image 6 PMMA-Yb(tta) under nitrogen atmosphere 3 ·The emission spectrum of DFQZ film at 78-328K. Unlike previously reported organic rare earth complexes, PMMA-Yb(tta) 3 ·The fluorescence intensity of DFQZ film increased significantly. At the same time, the temperature is increased from 78K to 328K, and the quantum yield of luminescence is increased by 5 times, from 0.2% to 1.0%.

[0087] Figure 7 a) and b) are PMMA-Yb(tta) under nitrogen and oxygen atmosphere respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com