Cleaning and drying instrument for laboratory test tubes

A laboratory and test tube technology, applied in the field of test tube cleaning and drying instruments, can solve the problems of the inner wall of the test tube cannot be used immediately, prolonging the drying time, shortening the time and quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

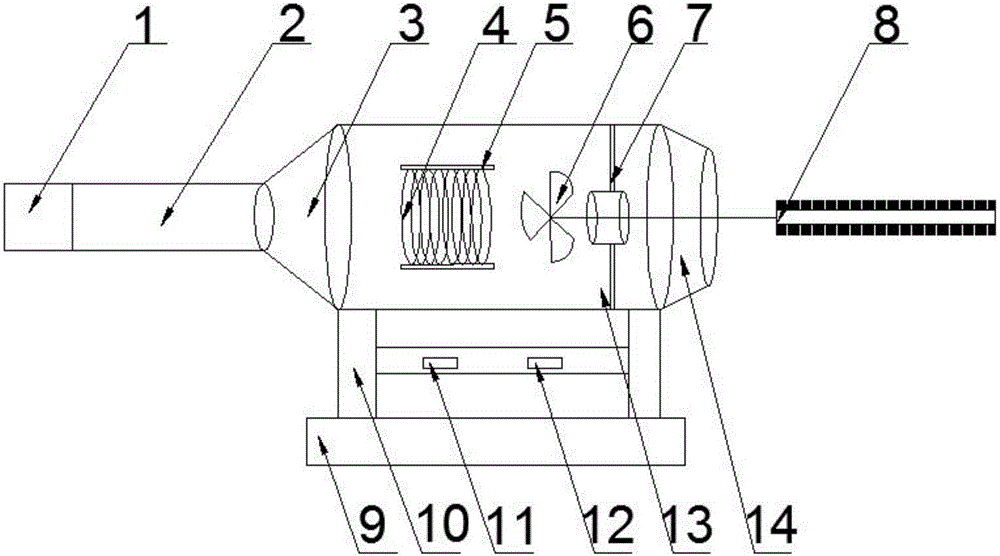

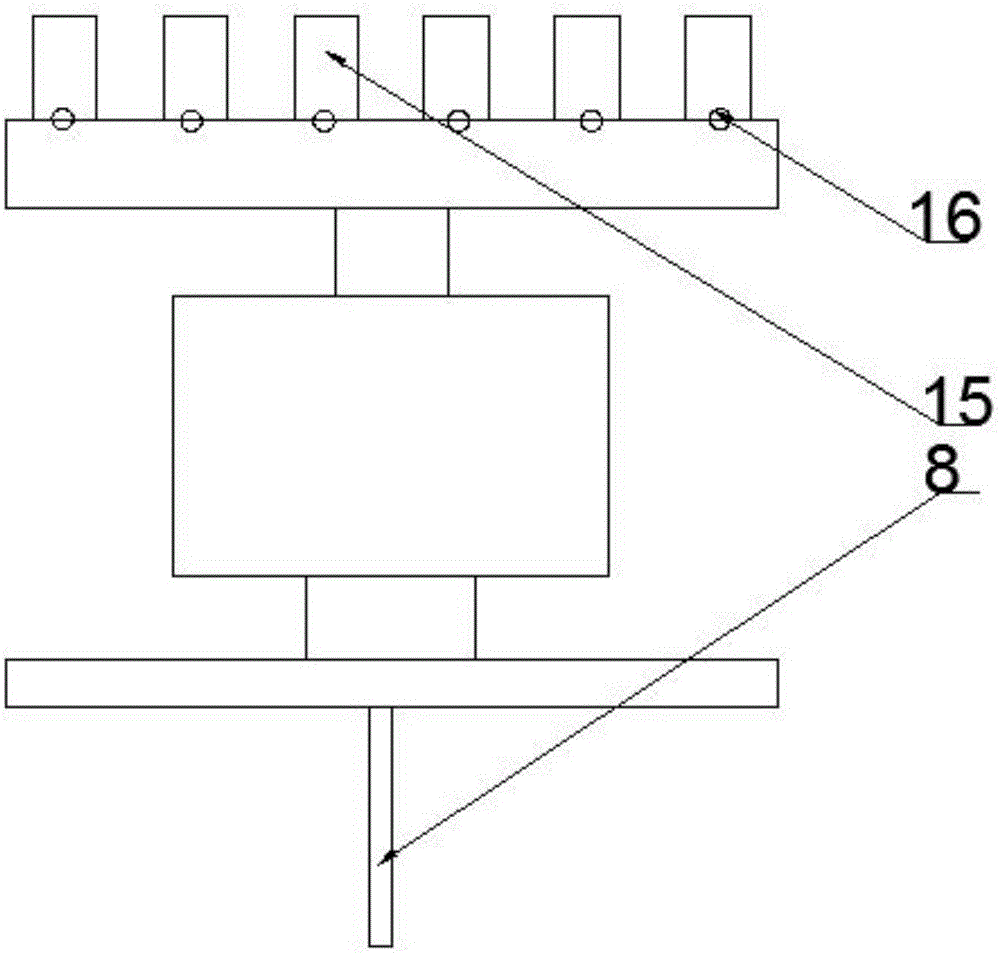

[0016] see Figure 1-2 , this embodiment provides a laboratory test tube cleaning and drying instrument, including a test tube port 1, a gas storage pipeline 2, a tapered gas outlet 3, an electric furnace wire 4 and a heat insulating board 5; the electric furnace wire 4 is installed and fixed on the heat insulating board 5, the heat insulation board 5 is fixed on the inner wall of the working chamber 13; the left side of the working chamber 13 is fixedly connected to the conical gas outlet 3, the gas storage pipeline 2 is fixed to the conical gas outlet 3, and the gas generated passes through the working chamber 13 flows through the tapered gas outlet end 3 and reaches the gas storage pipeline 2; the gas storage pipeline 2 is fixedly connected with multiple rows of test tubes 15, and each test tube port 1 is equipped with an air inlet valve 16, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com