Wire coiling method for axial-flow fan guard

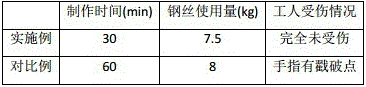

A technology of fan net cover and machine net cover, which is applied in the processing field of fan net cover, which can solve the problems of easy injury, large waste, slow speed, etc., and achieve the effects of cost saving, accuracy assurance and simple adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

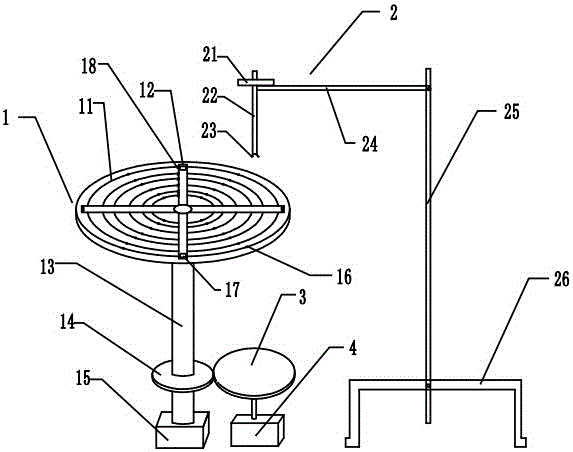

[0026] The fan guard processed in the present embodiment comprises four ring travelers and four sub-bars, and the fan guard coiling wire method of the present embodiment comprises the following steps:

[0027] Step 1: Select the whole roll of steel wire, put the whole roll of steel wire on the support plate on the support column, find out the wire end of the steel wire, and put the wire end of the steel wire on the Y-shaped positioning head;

[0028] Step 2: Let the positioning head be placed in the fan-shaped groove of the mesh pan, and adjust the cross bar and support rod so that the positioning head is located in the fan-shaped groove on the mesh pan;

[0029] Step 3: Press the wire head into the fan-shaped groove by the positioning head, and then turn on the stepping motor, let the stepping motor drive the driving gear to start rotating, and the driving gear drives the driven secondary wheel to rotate, so that the mesh disc rotates, and the positioning head The steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com