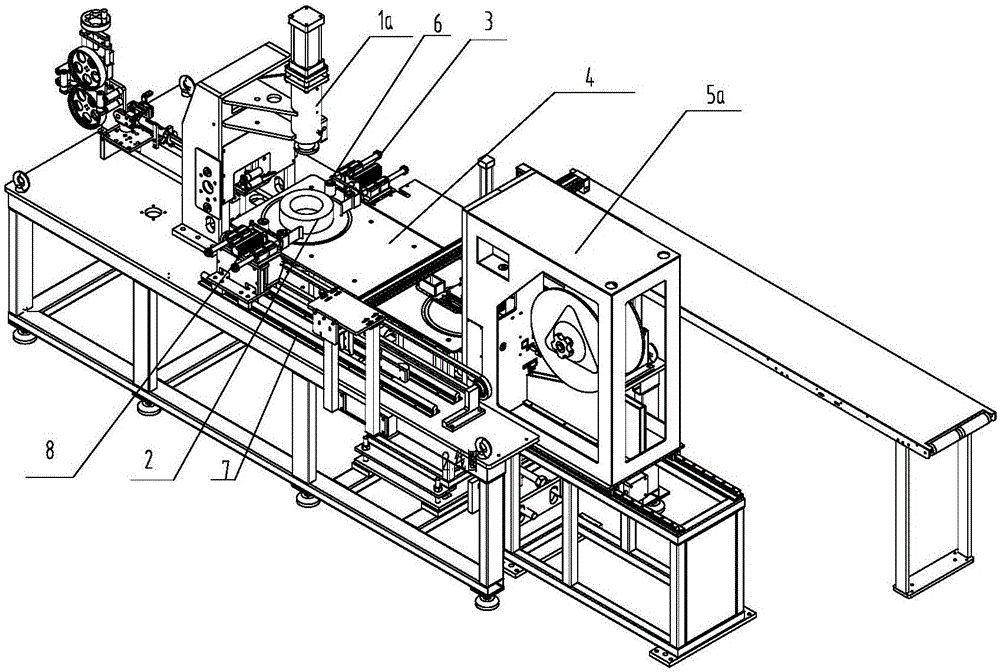

Coil forming and binding production unit with four circumferential stations

A four-station, cable tie technology, which is applied to conveyor objects, packaging, and conveying filamentous materials, etc., can solve problems such as equipment damage, restricting the degree of automation of production equipment, production stability and production efficiency, and looseness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

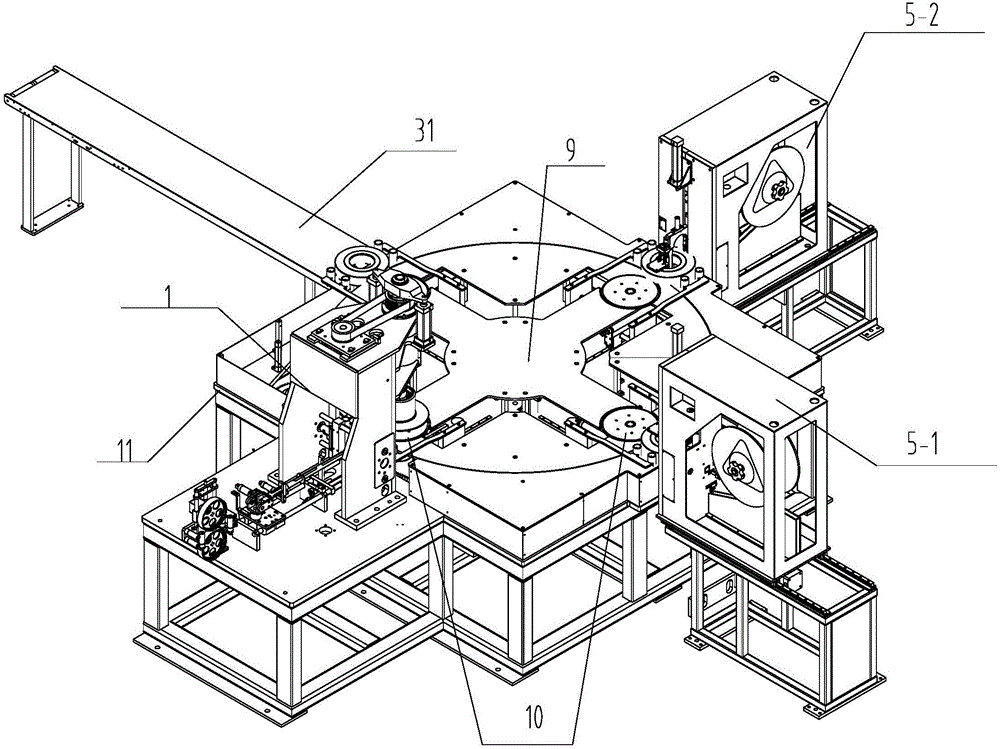

[0025] Refer to attached Figure 2-9

[0026] The circle four-station coil tie production unit consists of a frame 11, a loop take-up machine 1, and a tie tie machine 5 (the loop take-up machine 1 and tie machine 5 are connected to the figure 1 The coil forming machine 1a and the cable tie machine 5a have the same structure) and the circular four-station conveying turntable 9 (see figure 2 ); the looping wire take-up machine 1 and the cable tie machine 5 are distributed along the circumference of the four-station conveying turntable 9 and installed on the frame 11. In order to improve production efficiency, two cable tie machines are used.

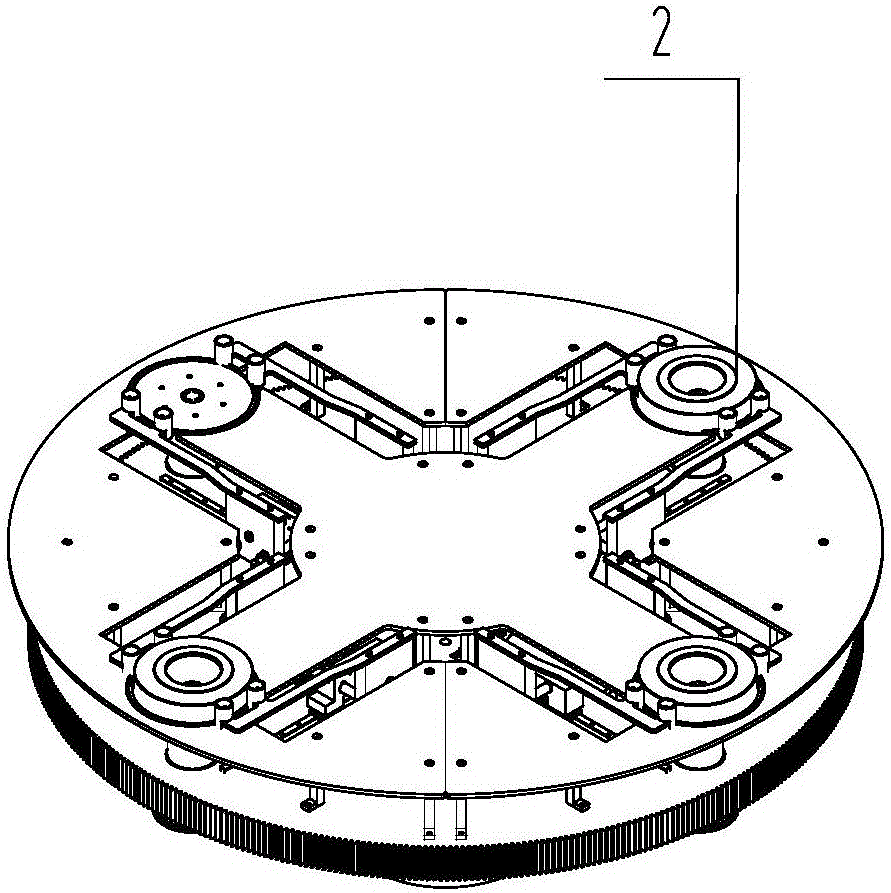

[0027] The circular four-station delivery turntable 9 is composed of a fixed rotating shaft seat 12, a rotating disk body 13, an arm device 16 and a lower take-up reel 10 (see Figure 3-Figure 5 );

[0028] Fixed rotating shaft seat 12 is installed on the frame 11, is made up of fixed seat 19, rotating shaft 17, bearing 18 (see Imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com