Variable-gain valve

A variable gain and valve body technology, applied in the field of hydraulic valves, can solve problems such as increased difficulty in installation and adjustment, poor applicability, and increased product complexity, and achieves the effects of convenient use, high reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

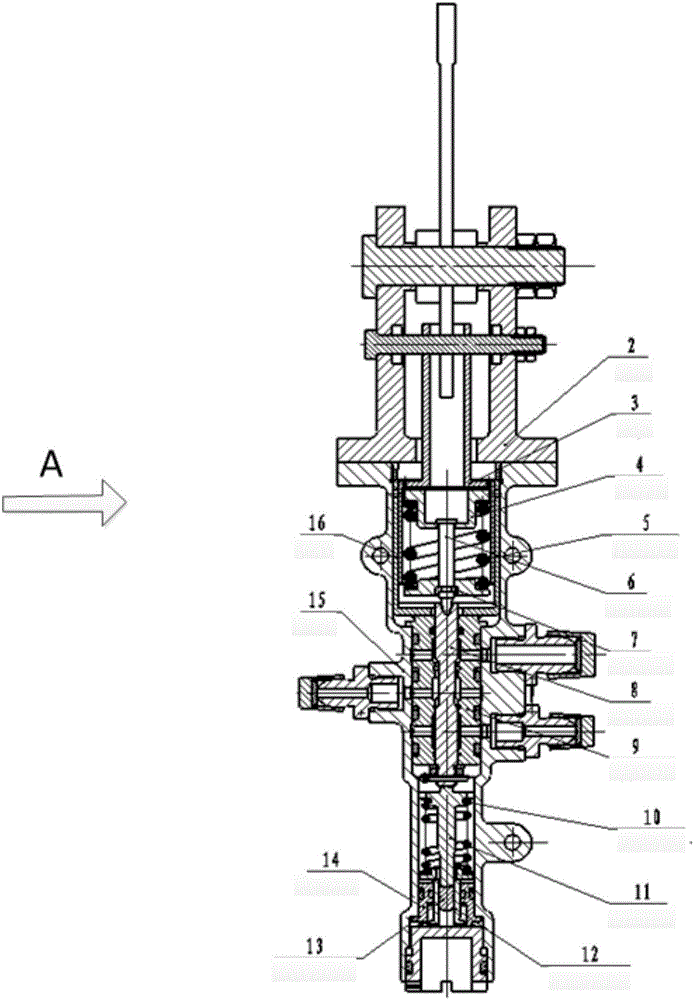

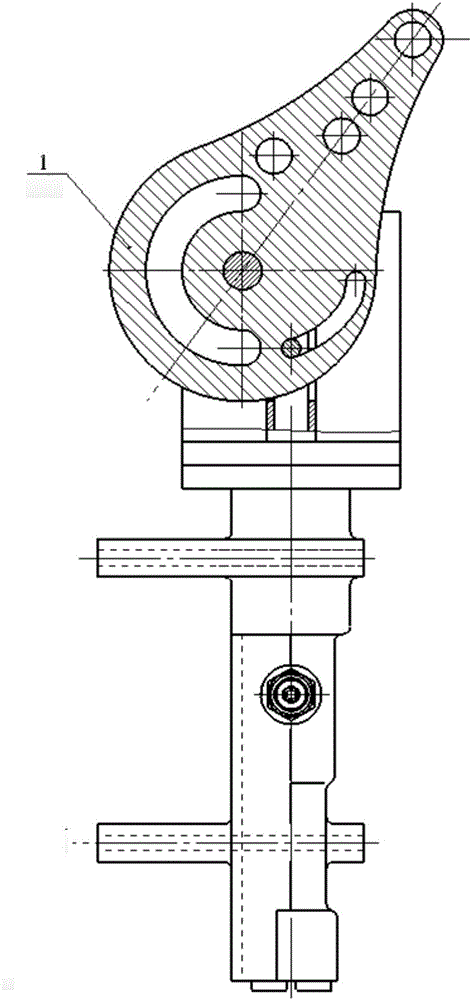

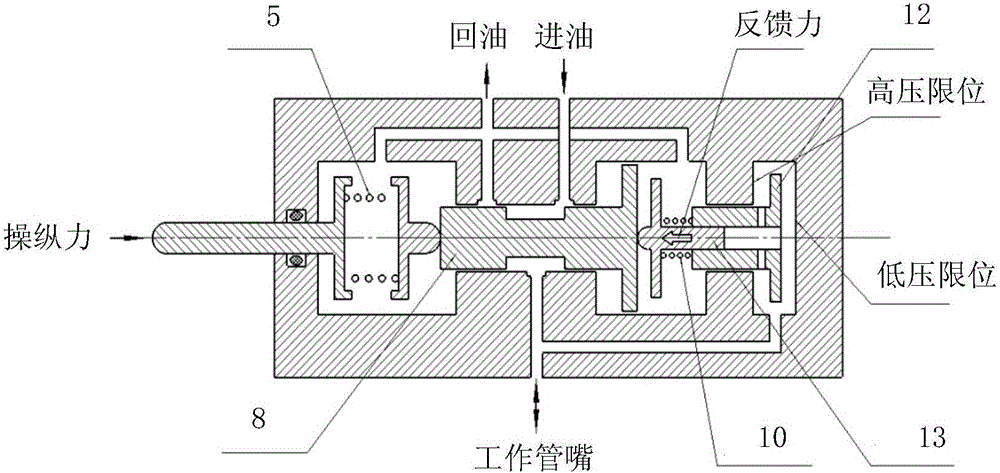

[0020] like figure 1 and 2 As shown, a variable gain valve is characterized in that: the gain valve includes a cam 1, a bracket 2, a sleeve 3, a spring seat 4, a decompression spring 5, a push rod 6, a valve body, a feedback spring 10, a feedback Rod 11, large feedback piston 12 and small feedback piston 13;

[0021] On one side of the valve body: the cam 1 is installed on the bracket 2 through the rotating shaft, and the cam 1 is provided with an arc-shaped surface, and the arc-shaped surface includes a variable-diameter arc-shaped surface segment and an equal-diameter arc-shaped surface segment. The contour line of the variable-diameter arc surface segment has the same center, and the distance between the contour line of the surface and the center of the circle increases gradually. The contour line of the surface segment is the same circle center, and one end of the connecting rod on the sleeve 3 is in contact with the arc surface;

[0022] The spring seat 4 and the decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com