High-efficiency bench blasting method for interbedded rock mass

A technology of step blasting and rock mass, which is applied in the field of rock mass blasting, can solve the problem of high block rate, and achieve the effect of low cost, strong adaptability and good field operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

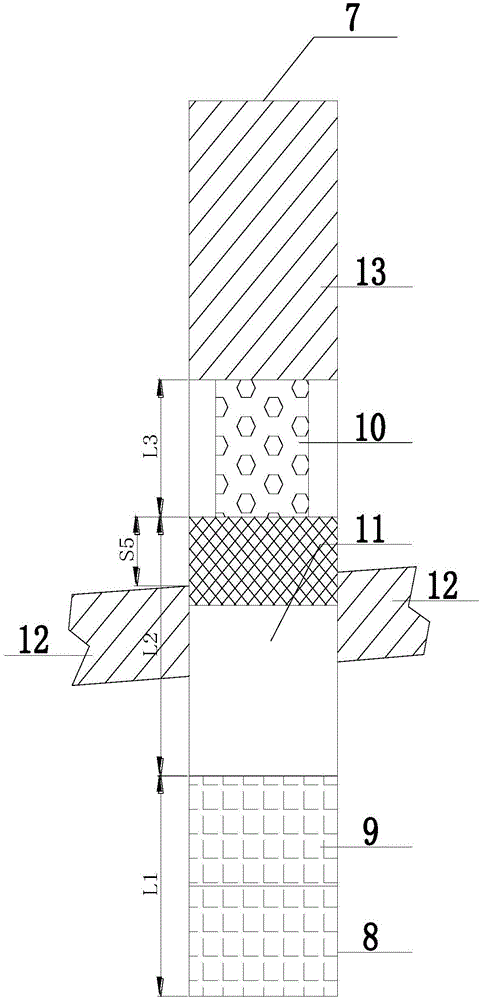

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, but the embodiments of the present invention are not limited thereto.

[0030] Optimum embodiment: take a certain open-pit coal mine as an example to explain the blasting method of the present invention, which will be specifically described below in conjunction with the accompanying drawings:

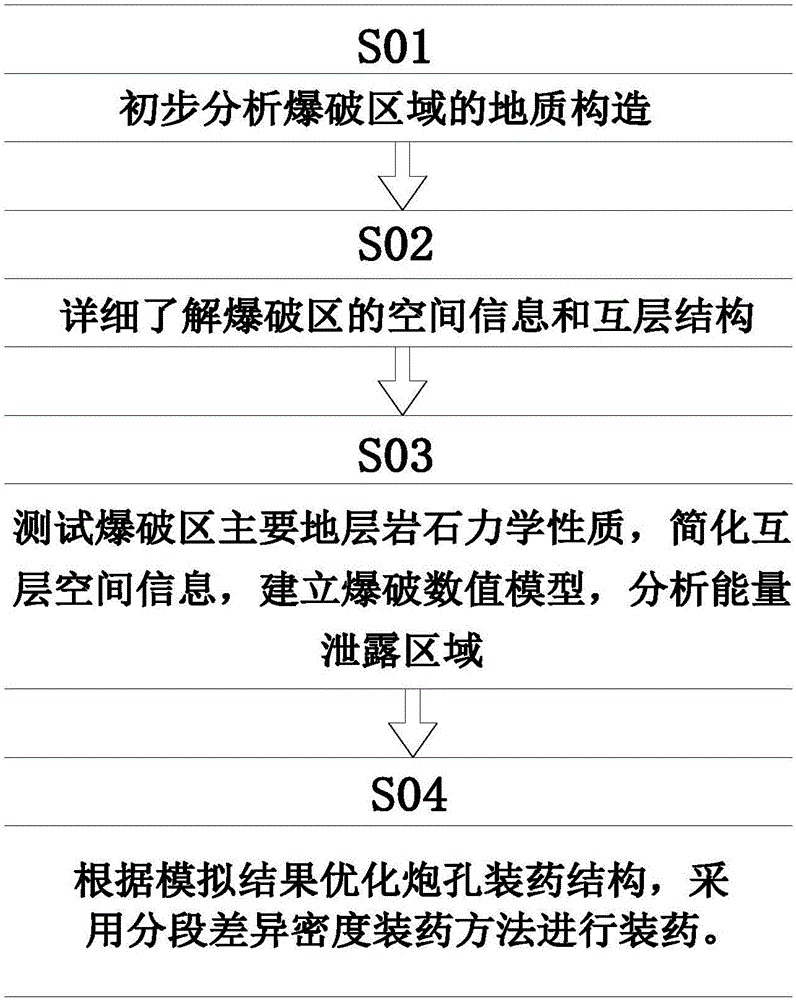

[0031] like figure 1 As shown, a high-efficiency step blasting method for interbedded rock mass, its implementation steps are as follows:

[0032] S01: Preliminary analysis of the geological structure of the blasting area based on the existing geological data;

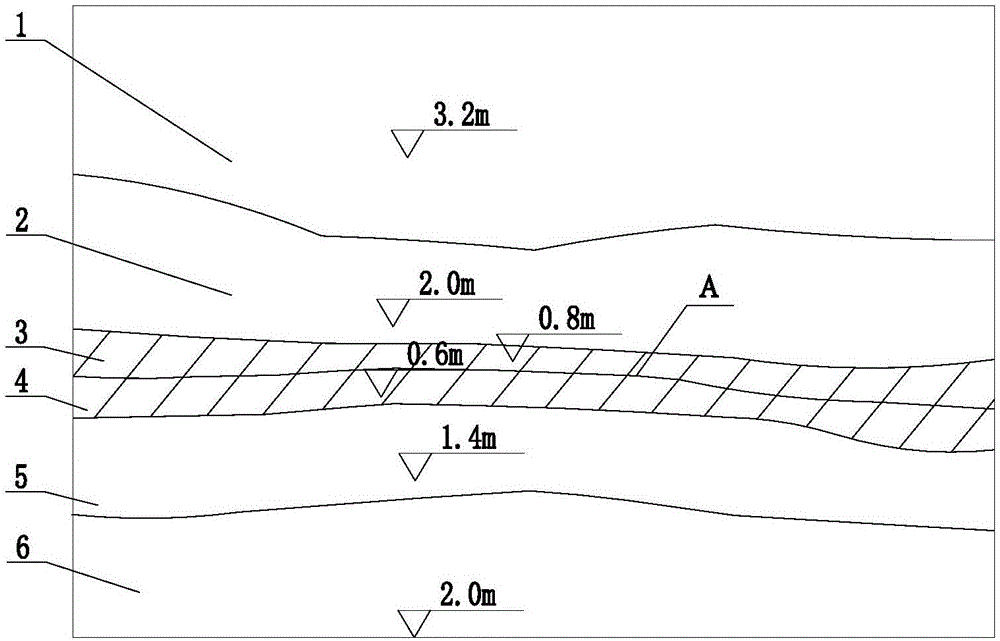

[0033] like figure 2 As shown, the step height of this open-pit coal mine is 10m, and the inclination angle of the main coal seam 6 is between 0° and 5°. Leakage, flying sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com