Assembled special-shaped-column-structured loading device and test method thereof

A technology of loading device and special-shaped column, which is applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of complex joint connection structure, difficult construction, and difficulty in ensuring the structure of cast-in-place special-shaped columns, etc. , to achieve the effect of simple operation, high measurement accuracy and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

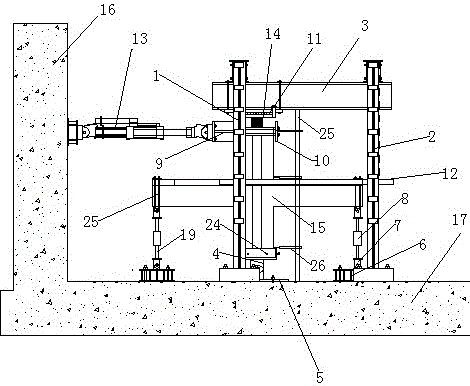

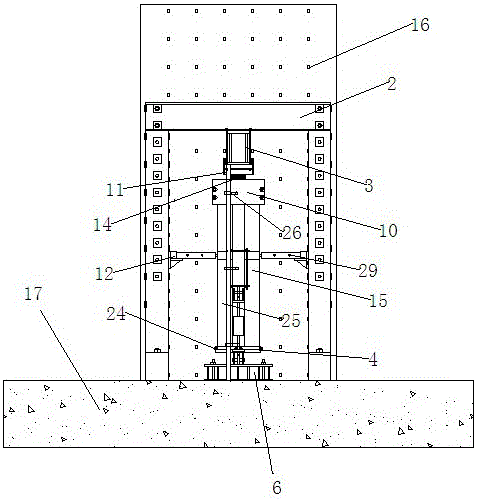

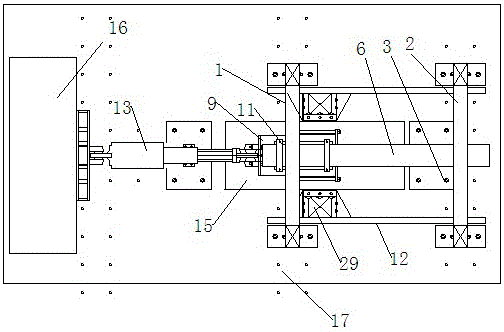

[0061] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0062] attached Figure 1-11 It can be seen that an assembled special-shaped column structure loading device,

[0063] Including: left gantry 1, right gantry 2, pressure beam 3, column support, lateral support 12, actuator loading head 9, rolling friction support 11, displacement gauge 26 for collecting the displacement of special-shaped column 15 and beam end fixtures for special-shaped columns;

[0064] The left door frame 1 is parallel to the right door frame 2;

[0065] The door frame includes a door frame beam and a door frame column; the door frame is in the shape of a door;

[0066] The two ends of the pressure beam 3 are connected with the portal beam by bolts;

[0067] The upper surfaces of the two ends of the pressure beam 3 are attached to the lower surface of the gantry beam;

[0068] The pressure beam 3 is perpendicular to the left mast 1 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap