Sound wave temperature-measuring sounding device and receiving device

A technology of a sounding device and a receiving device, which is applied in the direction of analyzing fluids, analyzing materials, and instruments using sound waves/ultrasonic waves/infrasonic waves, which can solve problems such as large measurement errors, inconvenient maintenance, and short service life, and achieve simple structure and accurate measurement High-strength, small-volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

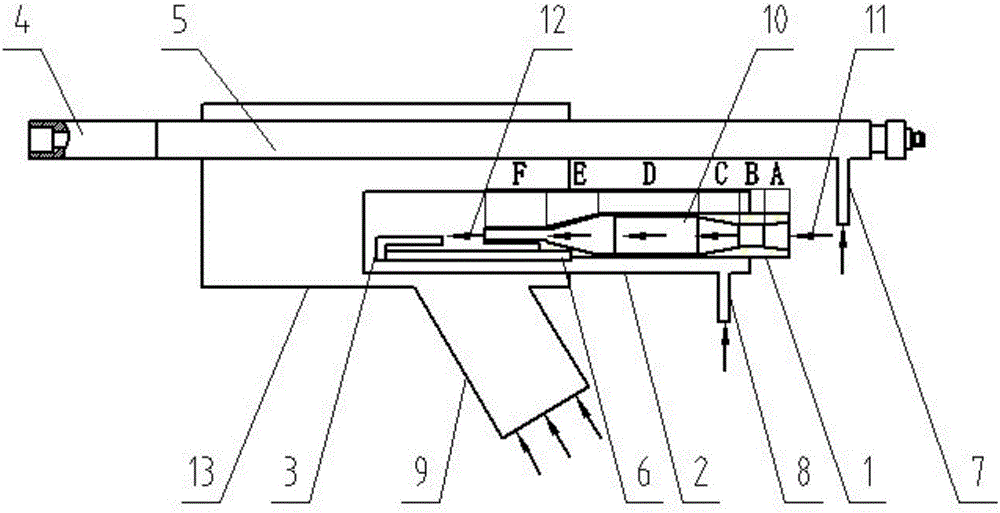

[0019] Examples such as figure 1 As shown, an acoustic temperature measurement and sounding device includes a mounting assembly 13 and a sounding cavity 2 arranged on the mounting assembly 13, and the sounding cavity 2 is a cylindrical structure. The sounding cavity 2 is fixedly provided with a nozzle 1 , the inlet end of the nozzle 1 extends out of the sounding cavity 2 , and the gas outlet end of the nozzle 1 is placed in the sounding cavity 2 . The nozzle 1 is arranged eccentrically in the sound emitting cavity 2 . A reed 3 is also provided in the sound emitting cavity 2 . The reed 3 is a cantilever structure with one end fixed. The end of the reed 3 is arranged opposite to the gas outlet end of the nozzle 1 . The reed 3 is fixed on the outer wall of the nozzle 1 through the connecting plate 6, the end of the reed 3 away from the nozzle 1 is connected to the connecting plate 6, and the end close to the nozzle 1 is a free end. The distance between the nozzle 1 and the reed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com