Method for calculating sieve plate extraction tower liquid flow field by using low Reynolds number turbulence model

A technology of turbulent flow model and low Reynolds number, applied in calculation, electrical digital data processing, design optimization/simulation, etc., can solve problems such as unfavorable two-phase contact mass transfer and high flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

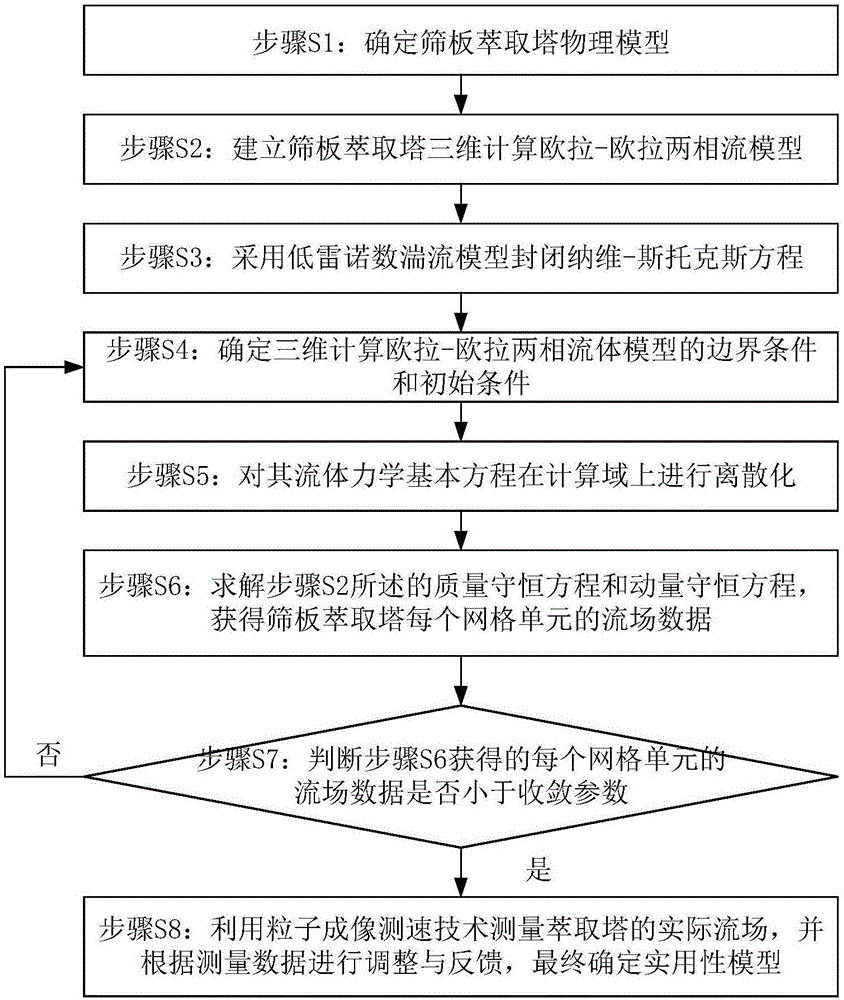

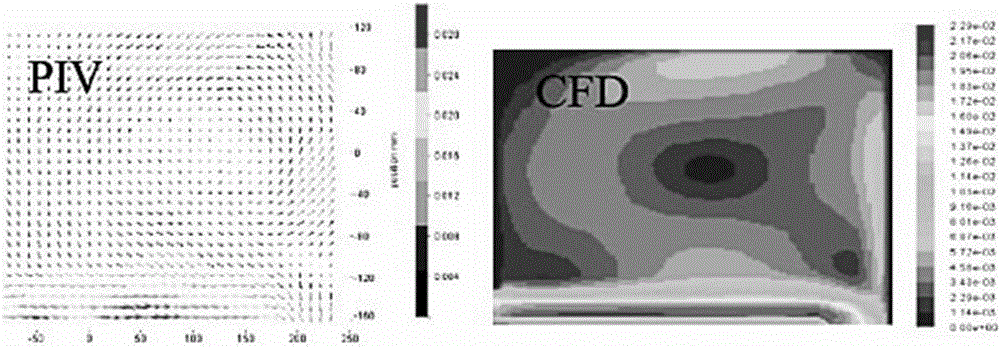

[0082] Such as Figure 1-6 As shown in one of them, the invention discloses a method for calculating the liquid-liquid flow field of a sieve plate extraction tower using a low Reynolds number turbulence model, which includes the following steps:

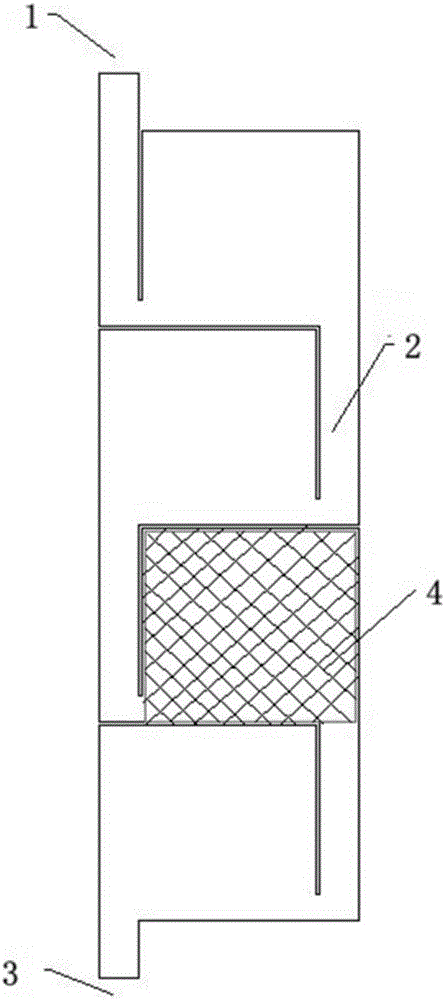

[0083] Step S1: determine the physical model of the sieve tray extraction tower, including the geometric structure of the physical model, the composition of the continuous phase and the dispersed phase and the calculation area; as a preferred embodiment, the sieve tray extraction tower in the step S1, the calculation area is the two-dimensional section of the extraction area of the sieve extraction tower;

[0084] In this embodiment, dilute acetic acid solution is used as the continuous phase, sec-butyl acetate is used as the dispersed phase, and the continuous phase flows in from the top of the tower as the heavy phase. to the next tray. The light phase, as the dispersed phase, enters from the bottom of the tower, disperses into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com