Tensile cable

A cable and tension-resistant technology, which is applied in the field of tensile cables, can solve the problems of increased manufacturing cost, strong force, and little strengthening effect of cable cores, so as to save manufacturing costs, ensure tensile properties, and facilitate large-scale popularization and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

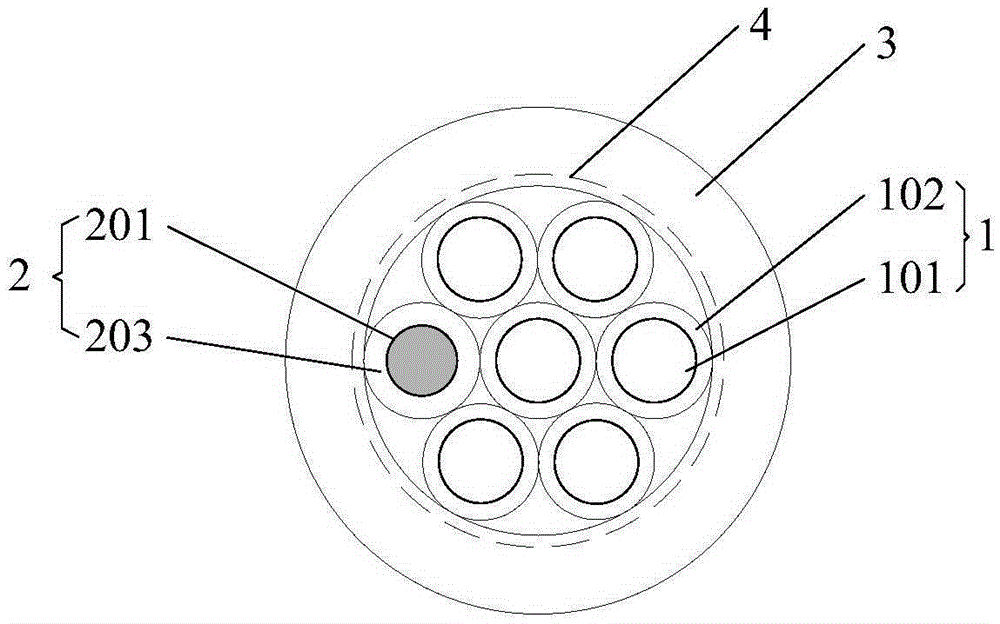

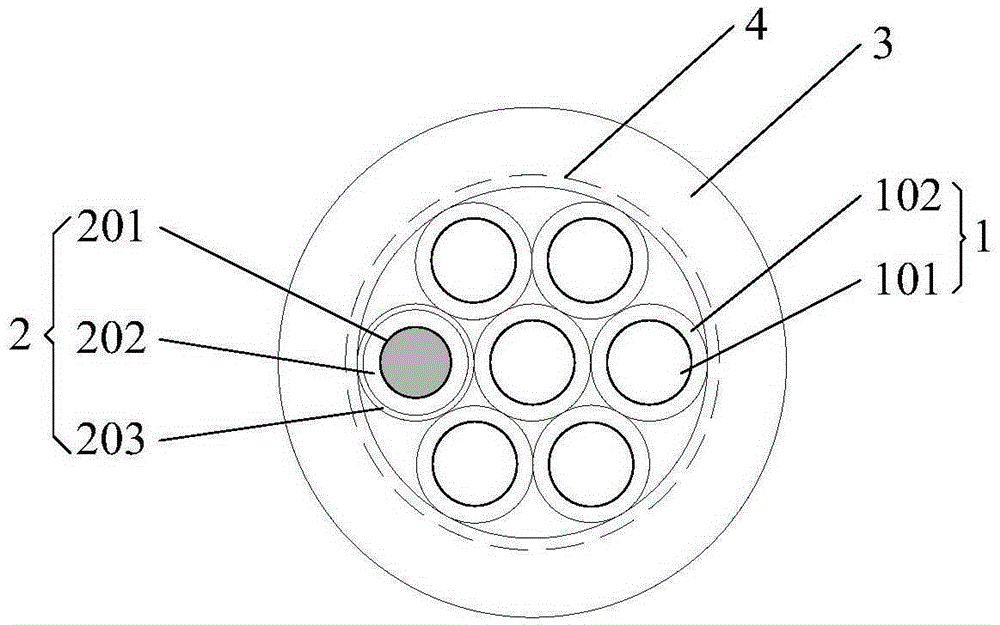

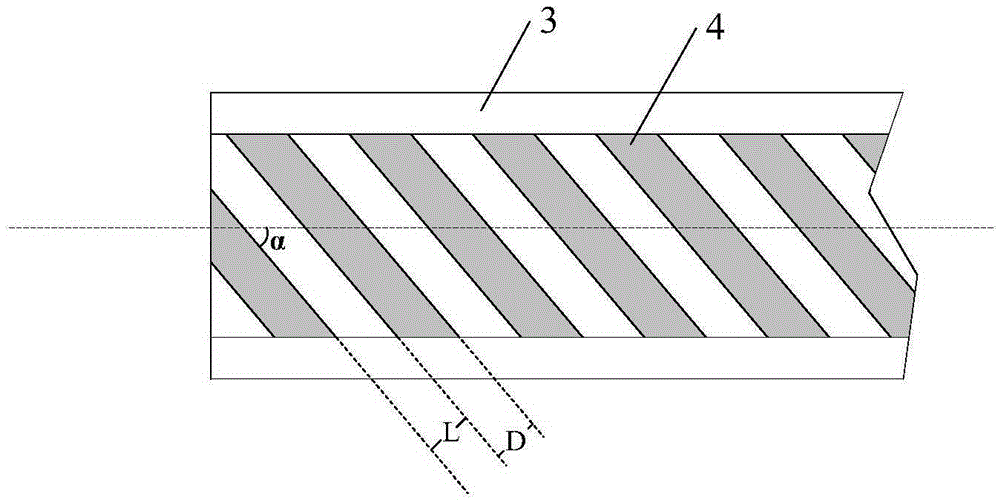

[0024] Such as figure 1 , 3 As shown, it is an embodiment of the tensile cable in the present invention, which is a cross section of 400mm 2 The tensile cable within, the tensile cable includes a conductive electric core 1, a tensile member 2, an outer sheath 3 and a wrapping tape 4, the conductive electric core 1 includes a wire 101 and an insulating layer 102 wrapped outside the wire 101, and the tensile Part 2 includes a steel wire rope 201 and a sheath layer 203 wrapped on the steel wire rope 201. The steel wire rope 201 is a tinned flexible steel wire rope, and the sheath layer 203 is made of nylon. The tensile parts 2 are arranged in parallel to form the inner core, the outer sheath 3 is wrapped on the inner core, and the cross section of the outer sheath 3 is circular; the wrapping tape 4 is spirally wound on the inner core, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com