OLED (organic light emitting display) packaging method and OLED packaging structure

一种封装方法、封装结构的技术,应用在有机发光器件结构、电气元件、电路等方向,能够解决破坏封装效果、不可控因素、工艺复杂等问题,达到提高封装效果、减少使用数量、生产成本低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

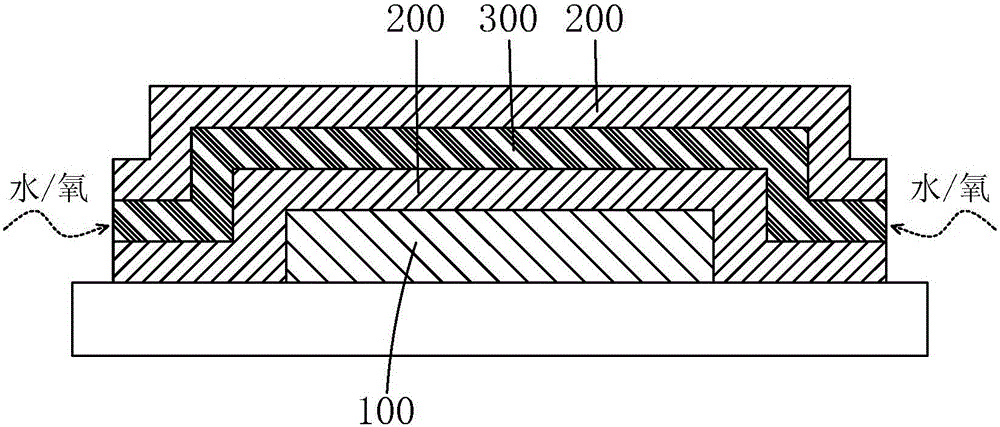

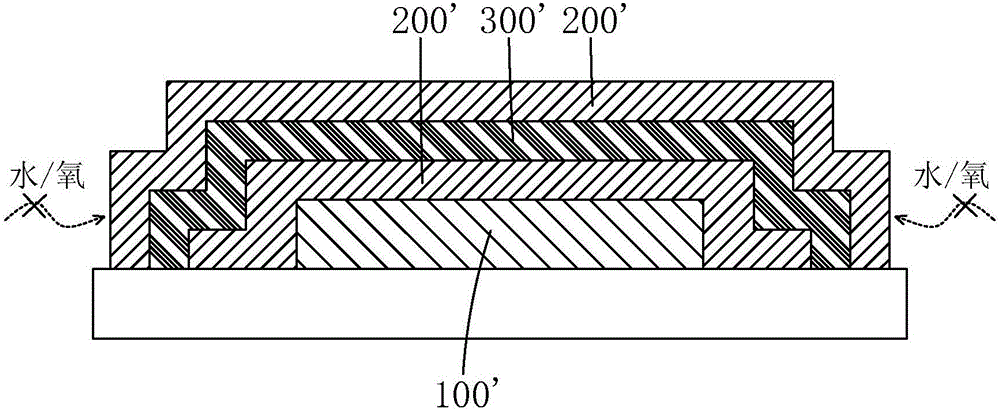

[0067] During the preparation process of the first organic layer 51, the first sealant 31 acts as a cofferdam to prevent overflow, and limits the size of the first organic layer 51, ensuring that the subsequent second inorganic layer 42 can be completely Covering the first organic layer 51 improves encapsulation effect.

[0068] Specifically, the thickness of the first organic layer 51 is 500 nm˜5 μm.

[0069] Specifically, the preparation method of the first organic layer 51 includes at least one of screen printing, spin coating, inkjet printing, and film casting.

[0070] Specifically, the first organic layer 51 is composed of organic resin. Preferably, the composition of the first organic layer 51 includes at least one of silicone resin and polymethyl methacrylate.

[0071] Specifically, the curing method of the first organic layer 51 includes at least one of thermal curing and UV curing. Preferably, the curing method of the first organic layer 51 is thermal curing.

[0...

example 1

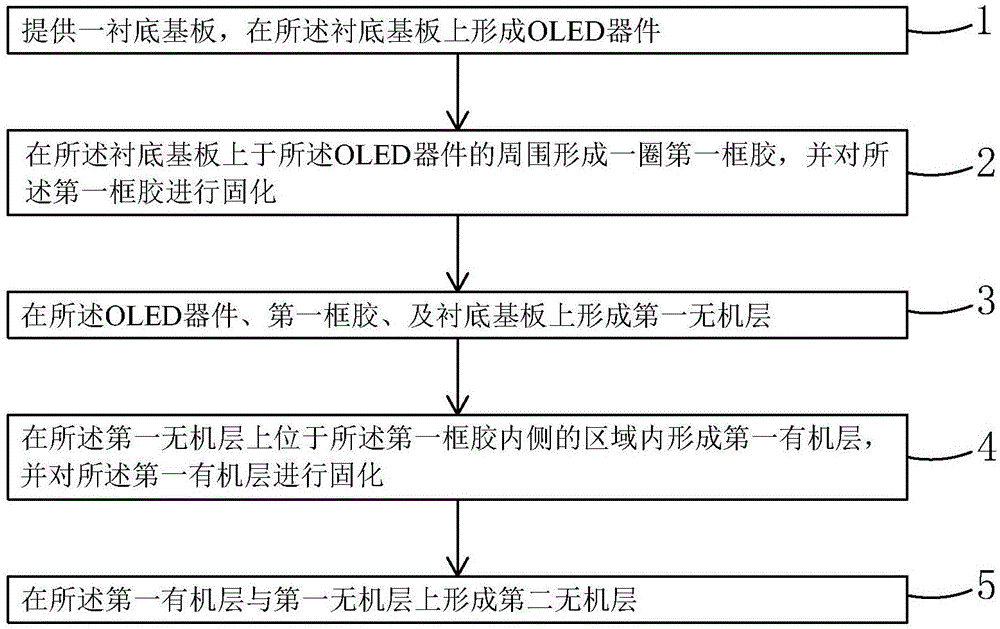

[0097] Step 1, such as Figure 4 As shown, a base substrate 10 is provided on which an OLED device 20 is formed.

[0098] Step 2, such as Figure 5 As shown, a circle of first sealant 31 is formed on the base substrate 10 around the OLED device 20 , and the first sealant 31 is cured.

[0099] The height of the first sealant 31 is 3 μm to 6 μm; the width of the first sealant 31 is 0.1 mm to 3 mm;

[0100] The distance between the inner edge of the first sealant 31 and the edge of the OLED device 20 is 1.0mm-1.5mm;

[0101] The main component of the first frame glue 31 is acrylic resin;

[0102] The curing method of the first sealant 31 is UV curing. During the UV curing process, the energy density of UV light is 3000mJ / cm 2 ~5000mJ / cm 2 , UV irradiation time is 30s ~ 100s.

[0103] Step 3, if Image 6 As shown, a first inorganic layer 41 is formed on the base substrate 10 and the OLED device 20, the first inorganic layer 41 covers the OLED device 20 and the first sealant...

example 2

[0112] Step 1, such as Figure 4 As shown, a base substrate 10 is provided on which an OLED device 20 is formed.

[0113] Step 2, such as Figure 5 As shown, a circle of first sealant 31 is formed on the base substrate 10 around the OLED device 20 , and the first sealant 31 is cured.

[0114] The height of the first rubber frame 31 is 10 μm to 15 μm; the width of the first rubber frame 31 is 1 mm to 2 mm;

[0115] The distance between the inner edge of the first sealant 31 and the edge of the OLED device 20 is 1.5mm-2mm;

[0116] The main component of the first sealant 31 is silicone resin;

[0117] The curing method of the first sealant 31 is thermal curing, and the thermal curing conditions are as follows: a heating temperature of 60° C. to 90° C. and a heating time of 30 minutes to 100 minutes.

[0118] Step 3, if Image 6 As shown, a first inorganic layer 41 is formed on the base substrate 10 and the OLED device 20, the first inorganic layer 41 covers the OLED device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com