A high-power solid-state laser

A solid-state laser, high-power technology, used in lasers, solid-state laser parts, laser parts and other directions, can solve problems such as inconvenience in use, inability to adjust laser power, and inability to greatly expand power, and achieve simple structure and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

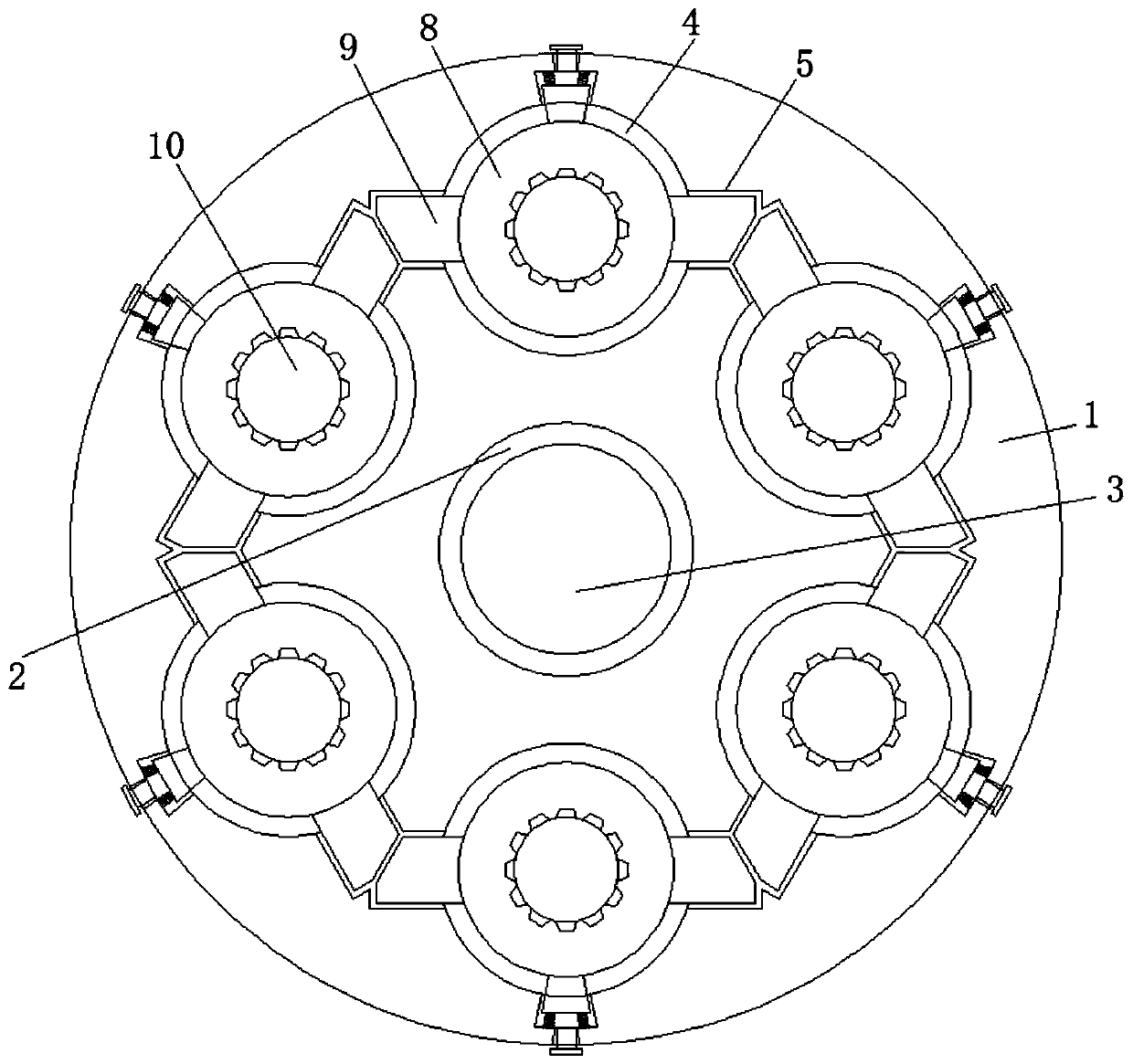

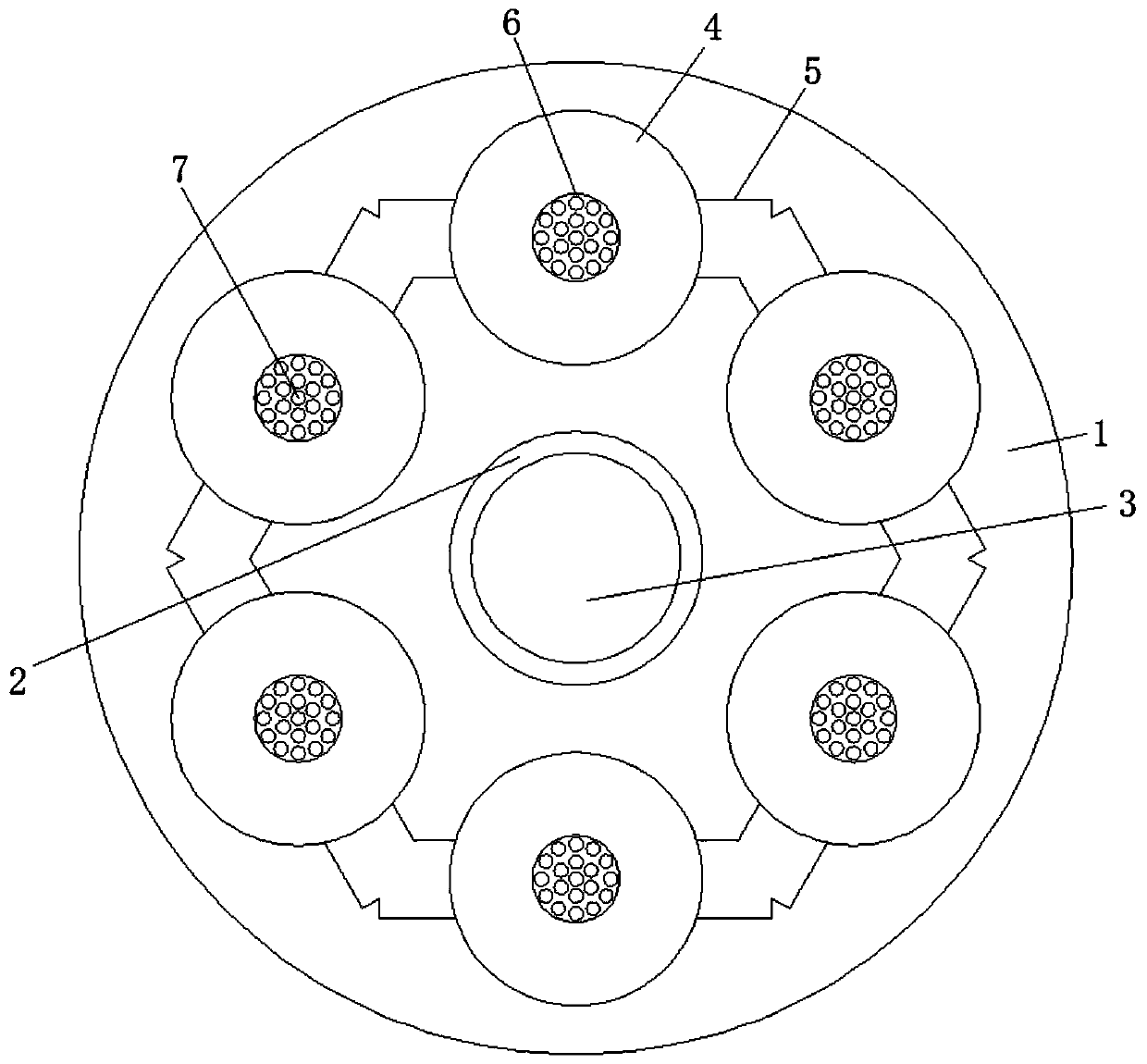

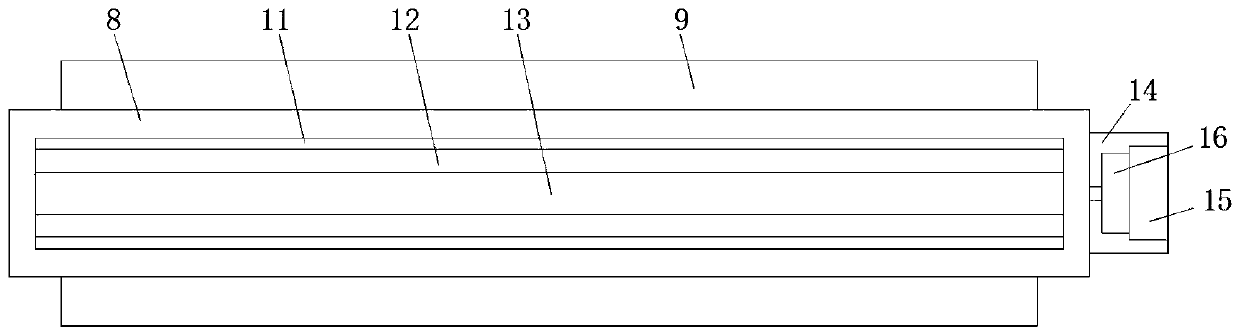

[0017] refer to Figure 1-3 , this embodiment proposes a high-power solid-state laser, including a housing 1, the housing 1 is a cylindrical structure, a first placement hole 2 communicating with the interior of the housing 1 is opened at the center of one end of the housing 1, and the second A laser rod 3 is fixedly installed in a placement hole 2, and one end of the laser rod 3 is fixedly installed in the center of the inner wall of the other end of the housing 1, and the first placement hole 2 is provided with a first opening at one end of the housing 1. Two placement holes 4, the inner walls of both sides of the second placement hole 4 are provided with card slots 5, and the periphery of the laser rod 3 is provided with a connecting seat 6 welded to the inner wall of the other end of the housing 1, on the connecting seat 6 The connector 7 is installed, and a placement seat 8 is placed in the second placement hole 4, and the side of the placement seat 8 close to the laser r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com