Automatic anti-heeling system using ballast pump

A ballast pump and heeling technology, which is applied in the field of ships, can solve the problems of large structure, many anti-tilting system equipment and complexity, and achieves the effect of saving pipelines, saving production cycle and large economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below with reference to the drawings and embodiments.

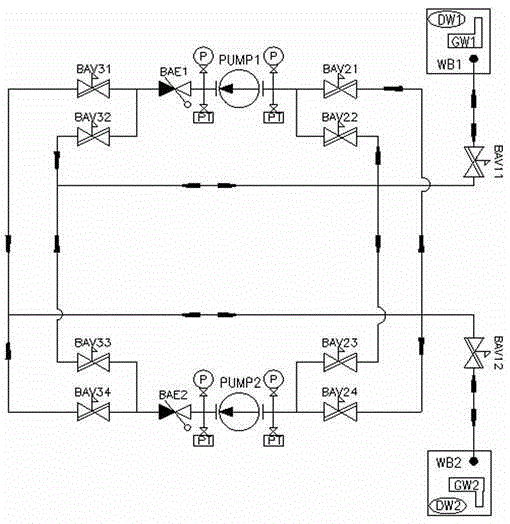

[0011] As shown in the figure, an automatic anti-rolling system using ballast pumps includes control systems, inclinometers, meters, ballast pumps PUMP1, 2, and remote control butterfly valves BAV11, 12, 21, 22, 23, 24, 31, 32, 33, 34, plate check valves BAE1,2, ballast tanks WB1,2, low level sensors DW1,2, high level sensors GW1,2, ballast pumps PUMP1 and 2 are equipped with instruments on both sides, pressure There are plate check valves BAE1 and 2 installed on the left side of the pumps PUMP1 and 2; two pipes are connected in parallel between the two plate check valves BAE1 and 2; the two ends of the inner pipe are connected with remote control butterfly valves BAV32, 33, and the outer pipe The two ends of the road are connected with remote control butterfly valves BAV31 and 34; the ballast pumps PUMP1 and 2 are connected with two pipelines in parallel on the right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com