Bituminous waterproof roll material film-covering correction device

A technology of asphalt waterproof roll material and correction device, which is applied in the direction of winding strip, transportation and packaging, thin material processing, etc. It can solve the problems of affecting waterproof performance, affecting product quality, and incomplete coverage of the film, so as to reduce the number of jobs , to avoid the effect of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

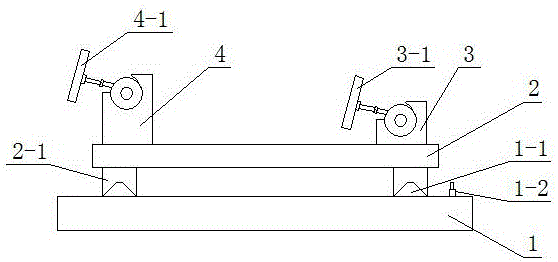

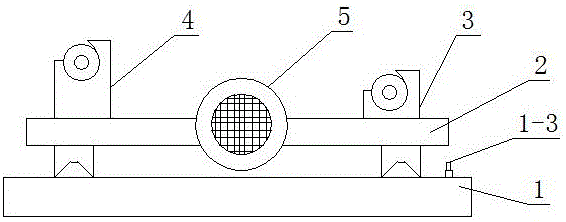

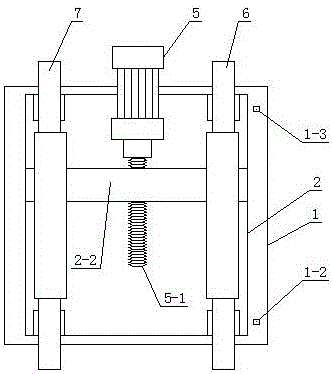

[0015] The asphalt waterproof membrane coating correction device is composed of a base plate 1, a movable support 2, 3 film roller installation frames, a spare film roller mounting frame 4 and a motor 5. The left and right sides of the bottom plate 1 are made with triangular slide rails 1-1, and the front and rear sides of the bottom plate 1 are symmetrically equipped with sensors A1-2 and sensors B1-3; 1 is installed on the bottom plate 1, and the upper part of the movable support 2 is symmetrically equipped with a film roller installation frame 3 and a spare film roller installation frame 4, and the film roller 6 is fixed on the film roller installation frame 3 through the locking bolt A3-1 On the top, the spare film roller 7 is fixed on the spare film roller installation frame 4 through the locking bolt B4-1, and the middle part of the movable support 2 is made with a connecting rod 2-2; The output shaft of 5 is connected with a screw rod 5-1 through a coupling, and the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com