Detachable assembly-type road steel bridge carrying and erecting vehicle

A dismantling and prefabricated technology, applied in construction and other directions, can solve the problems affecting the truss docking efficiency, the overall non-removal, and the fixed position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

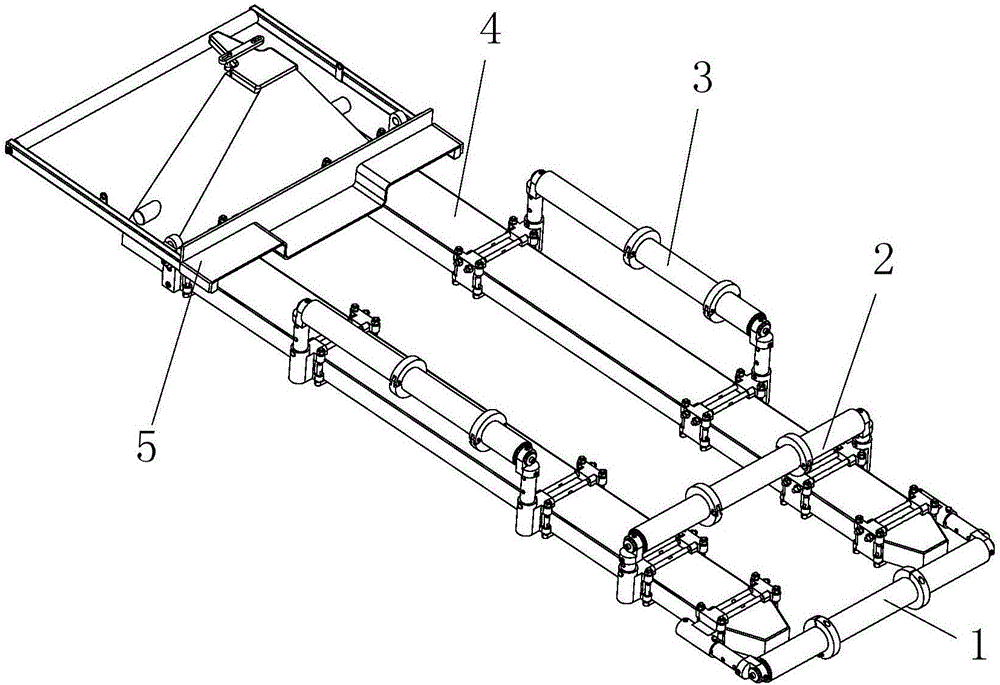

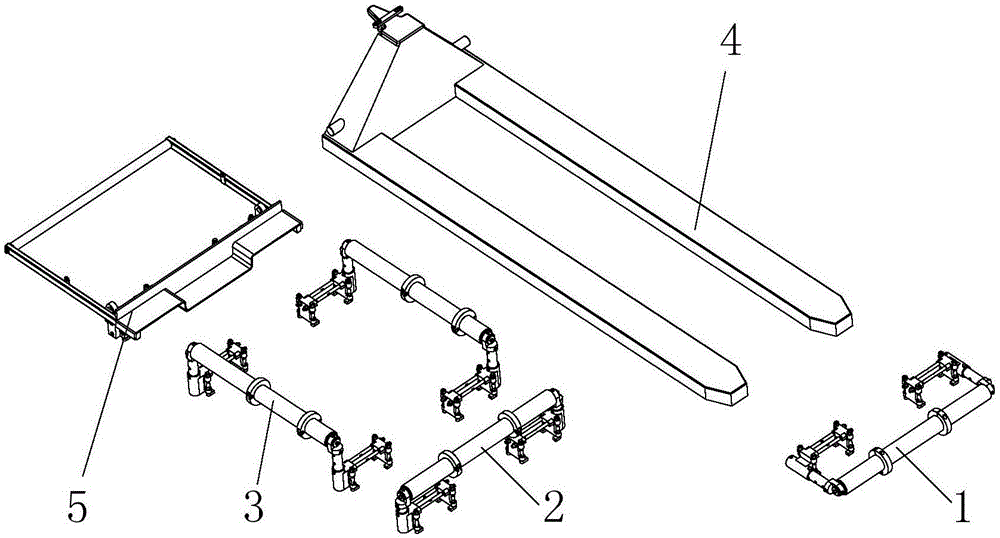

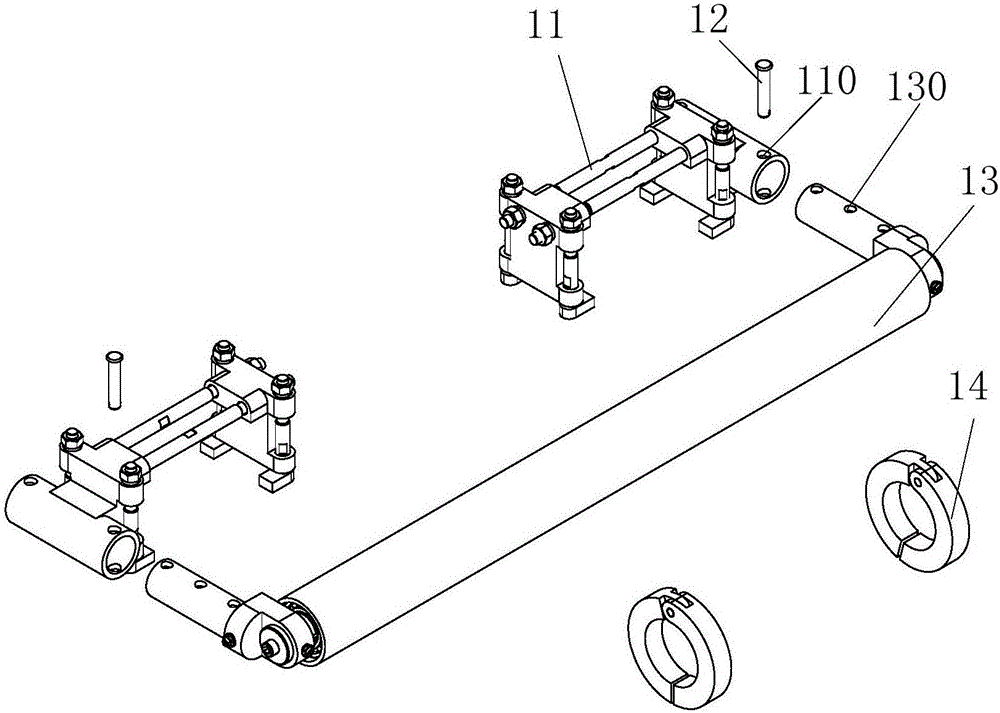

[0045] As shown in Figure 1(a) and Figure 1(b), the detachable assembled road steel bridge handling and erecting vehicle consists of a front lifting roller assembly 1, a middle lifting roller assembly 2, a side lifting roller assembly 3, and a vehicle body. 4 and the lifting plate assembly 5; the front lifting roller assembly 1 straddles the two forks of the car body 4 and is installed on the front side of the car body 4 in the horizontal direction; the middle lifting roller assembly 2 straddles the two forks of the car body 4 The fork is mounted on the middle side of the car body 4 in the vertical direction; the two side lift roller assemblies 3 are respectively installed on the two forks of the car body 4 along the longitudinal direction, and are respectively installed on both sides of the car body 4; the lifting plate assembly 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com