Fastening conductive mechanism convenient to operate and used for assembling aluminum electrolysis anode carbon block

An aluminum electrolytic anode and carbon block technology, which is applied in the field of convenient operation and fastening of conductive mechanisms, can solve the problems of inoperability, difficulty in maintaining regular shape, and reduced contact area, and achieves small occupied space, simple structure, and reduced occupied space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

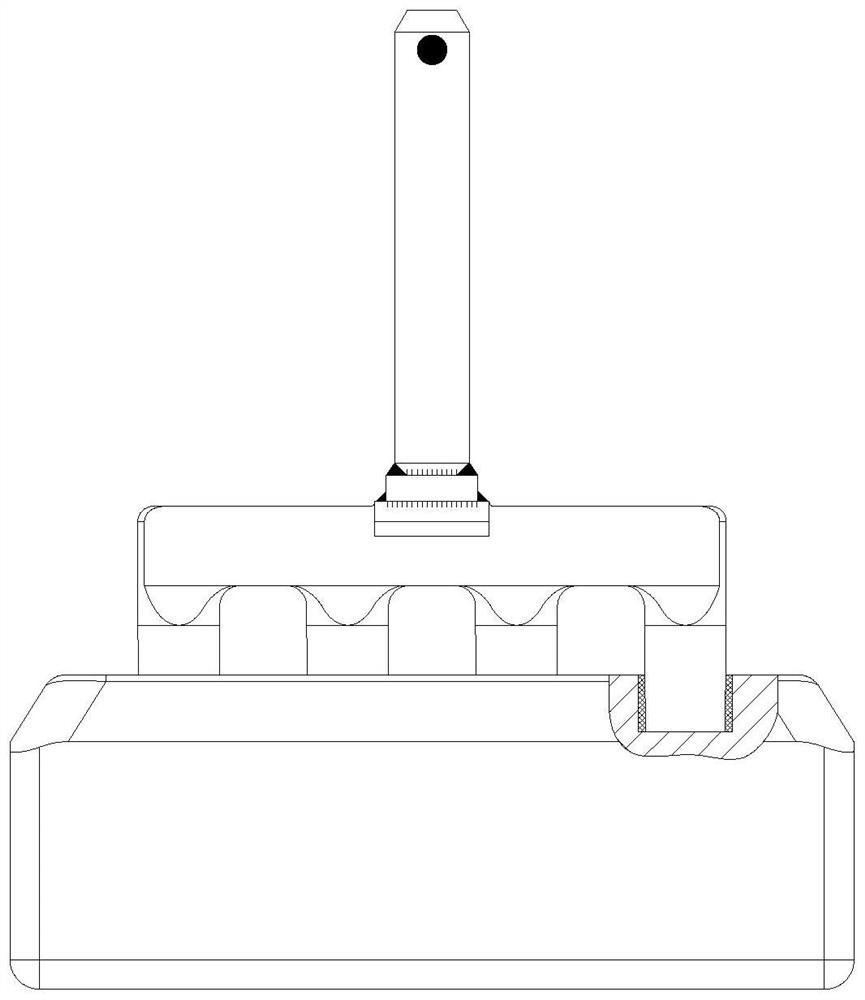

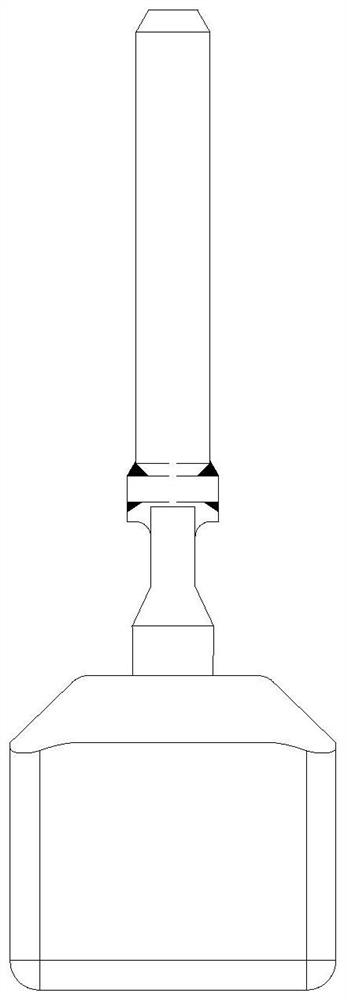

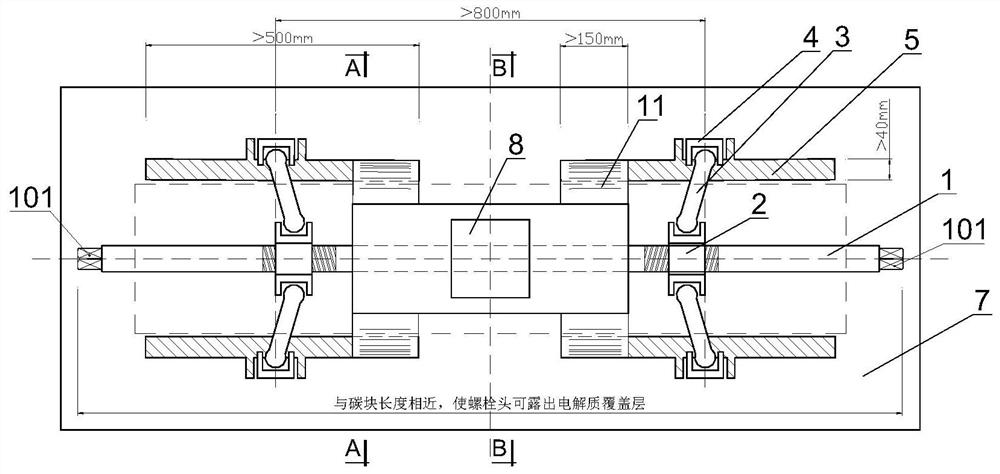

[0059] combine image 3 , Figure 4 , Figure 6 as well as Figure 8 As shown, a convenient operation fastening conductive mechanism for the assembly of aluminum electrolytic anode carbon blocks provided by the present invention includes an electrolyte shield 7, an aluminum guide rod 8, a threaded screw 1, and a conductive voltage plate 5; the aluminum guide The rod 8 is arranged on the top of the electrolyte guard plate 7; the bottom of the electrolyte guard plate 7 is provided with a bar-shaped groove 701, and the bar-shaped groove 701 is used to accommodate the clamping part of the anode carbon block 12; in the bar-shaped groove The two side walls of 701 are respectively provided with pressure plate holes 703; the conductive voltage plate 5 is arranged at the position of the pressure plate hole 703; the conductive voltage plate 5 and the electrolyte guard plate 7 are electrically connected through a conductor 11; The threaded screw 1 is arranged on the electrolyte shield...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com