Moisture-preventing drying device

A drying equipment and water-proof technology, which is applied in the direction of drying solid materials, drying chamber/container, lighting and heating equipment, etc. It can solve the problems of easy blowing and splashing of water droplets, rising water vapor, etc., and achieve the effect of ensuring the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

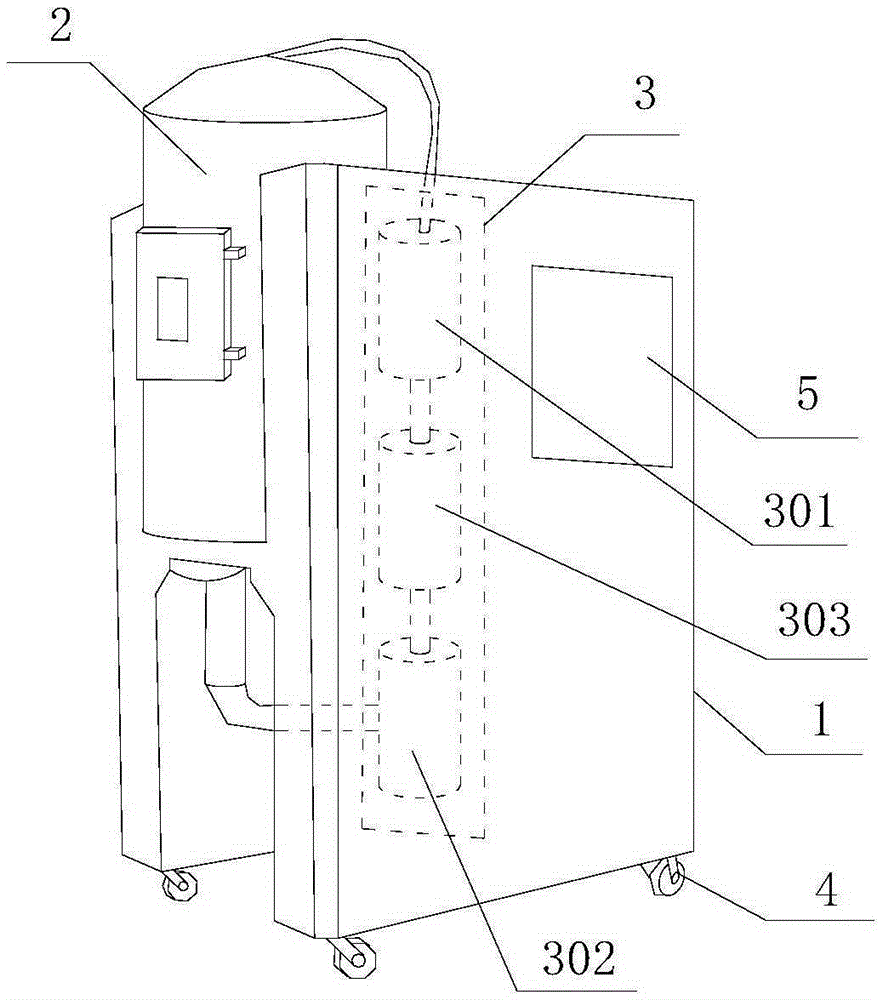

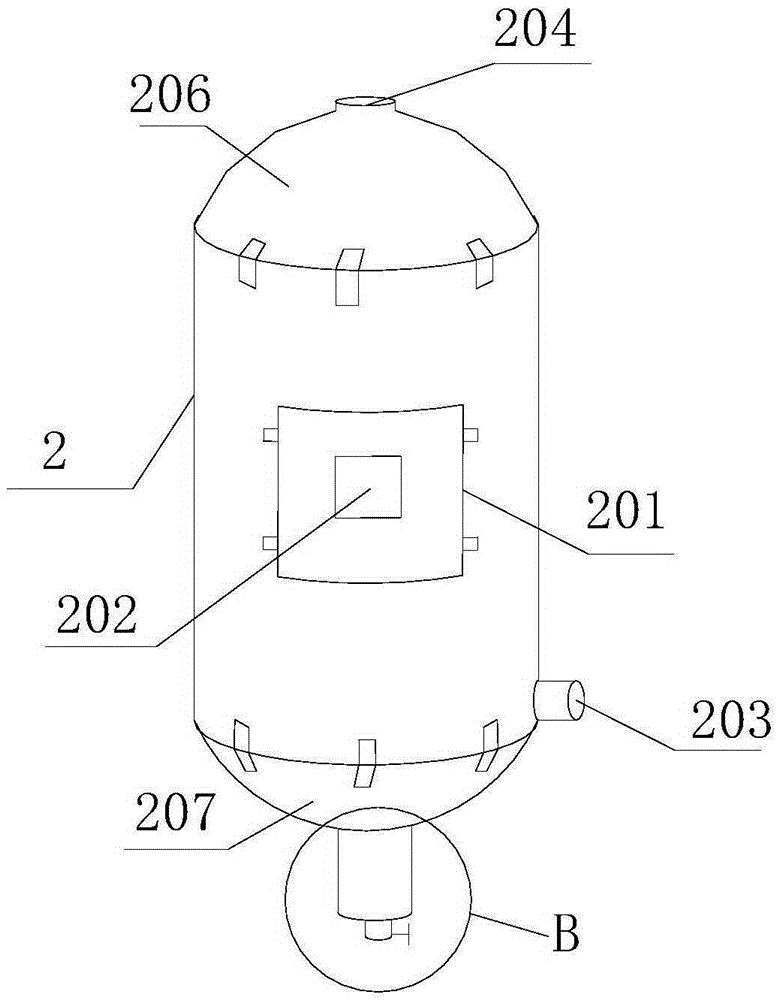

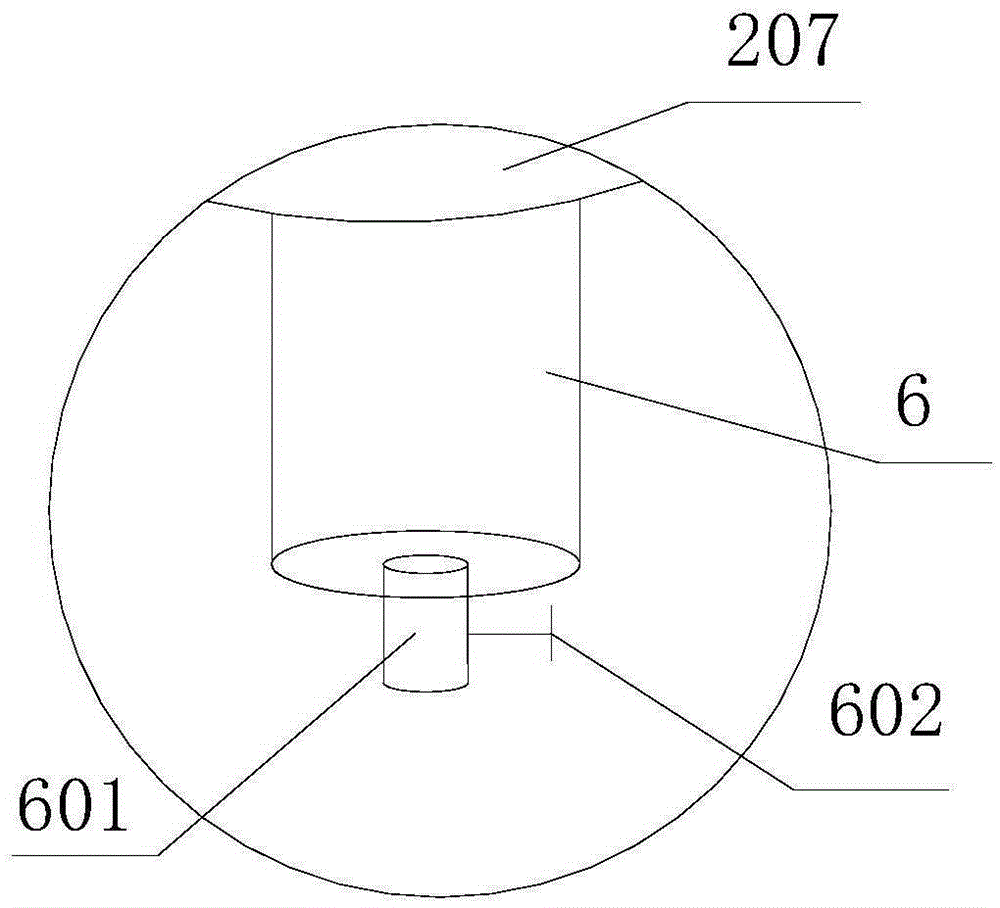

[0025] Such as Figure 1 to Figure 5 As shown, the waterproof air drying equipment includes a frame 1 and a drying cylinder 2 fixed on the frame 1. The drying cylinder 2 is in the shape of a hollow cylinder, and a material door 201 is arranged on its side, and the inside is matched with the material door 201 There is a material rack at the location, and an air inlet device 3 is provided on the frame 1. The air inlet device 3 includes an air pump 301, a heater 302, and a dryer 303. The air outlet of the air pump 301 is connected to the dryer 303 and the heater 302. The inlet 203 at the lower end of the drying cylinder 2 and the air inlet of the air pump 301 are connected to the outlet 204 at the top of the drying cylinder 2. The top of the drying cylinder 2 is provided with an upper cover 206. The upper cover 206 is in the shape of an inverted bowl. The cylinder 2 is hinged. The lower end of the drying cylinder 2 is provided with a lower cover 207. The lower cover 207 is in a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com