Equipment for co-extruding three layers of cables and automatically adjusting concentricity

A three-layer co-extrusion and automatic adjustment technology, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problem of asynchronous adjustment of the concentricity of the three co-extrusion heads, time-consuming and labor-intensive adjustments, and inaccurate adjustments, etc. problems, to achieve the effect of saving manpower, improving adjustment accuracy, and improving concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

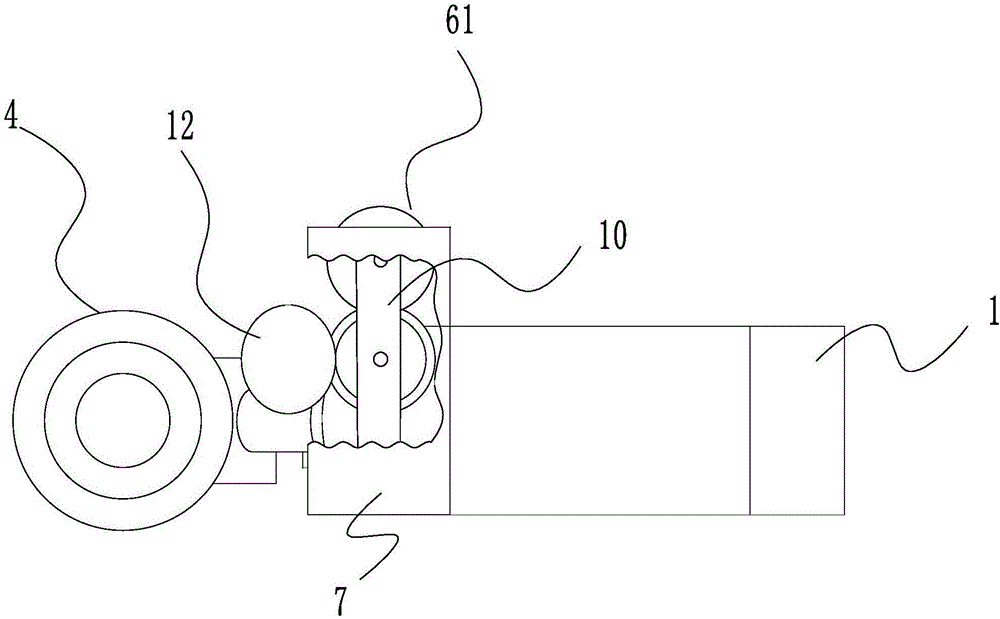

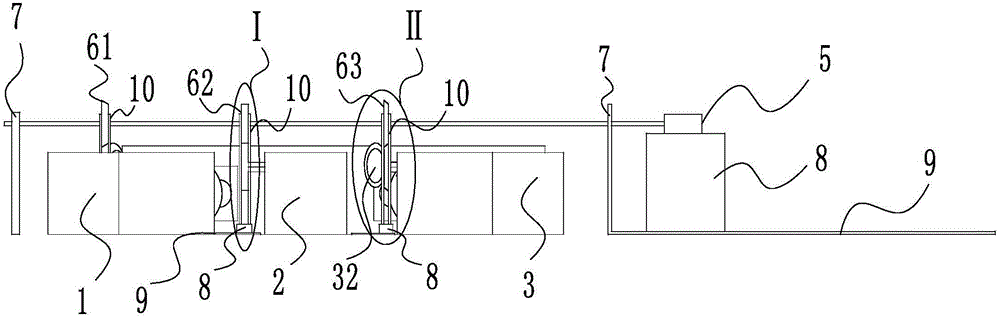

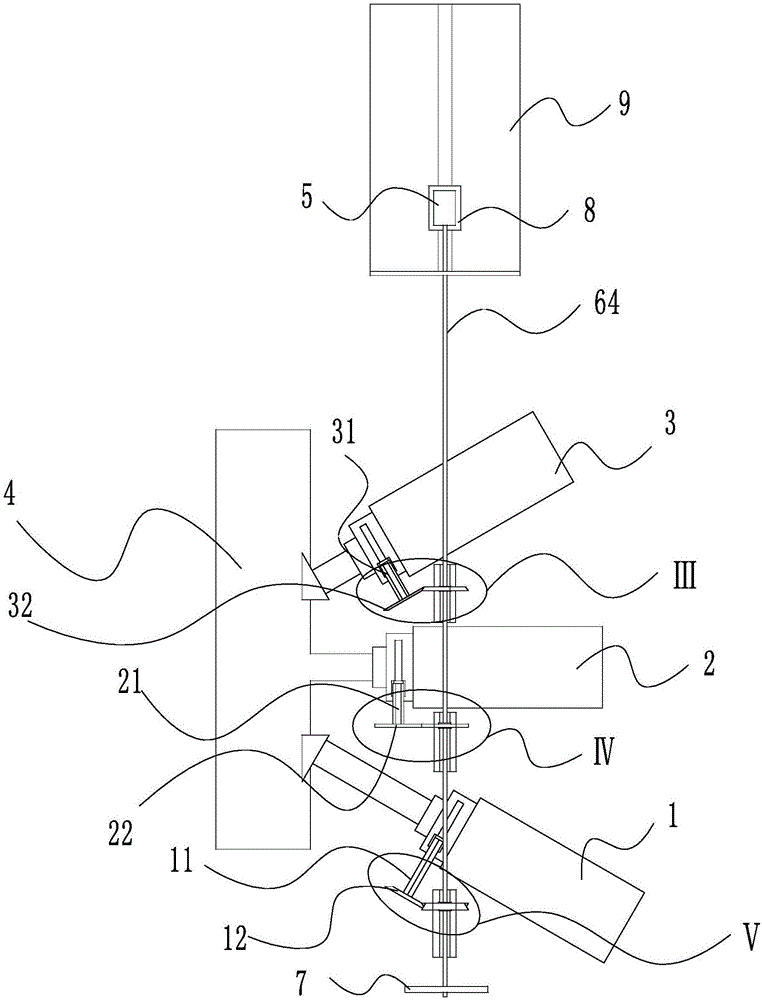

[0025] Such as Figure 1 to Figure 3 As shown, a three-layer cable co-extrusion automatic adjustment of concentricity equipment, including the first co-extrusion machine 1, the second co-extrusion machine 2, the third co-extrusion machine 3 and the barrel 4, the processed cable in the barrel 4 Passing through inside, the first co-extruder 1, the second co-extruder 2 and the third co-extruder 3 are installed at a certain angle on the right side of the barrel 4, the first co-extruder 1, the second co-extruder The first adjusting bolt 11, the second adjusting bolt 21 and the third adjusting bolt 31 perpendicular to the axis of the machine 2 and the third co-extruding machine 3 are respectively provided with. The first adjusting bolt 11, the second adjusting bolt 21, The twisting ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com