Rocker switch structure and switch socket thereof

A rocker switch and rocker technology, which is applied to parts, coupling devices, electrical components, etc. of flip switches/rocker switches, can solve problems such as infirmity, complicated assembly, false welding or false welding, etc., and achieve product reliability High performance, lower manufacturing costs, and fewer manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

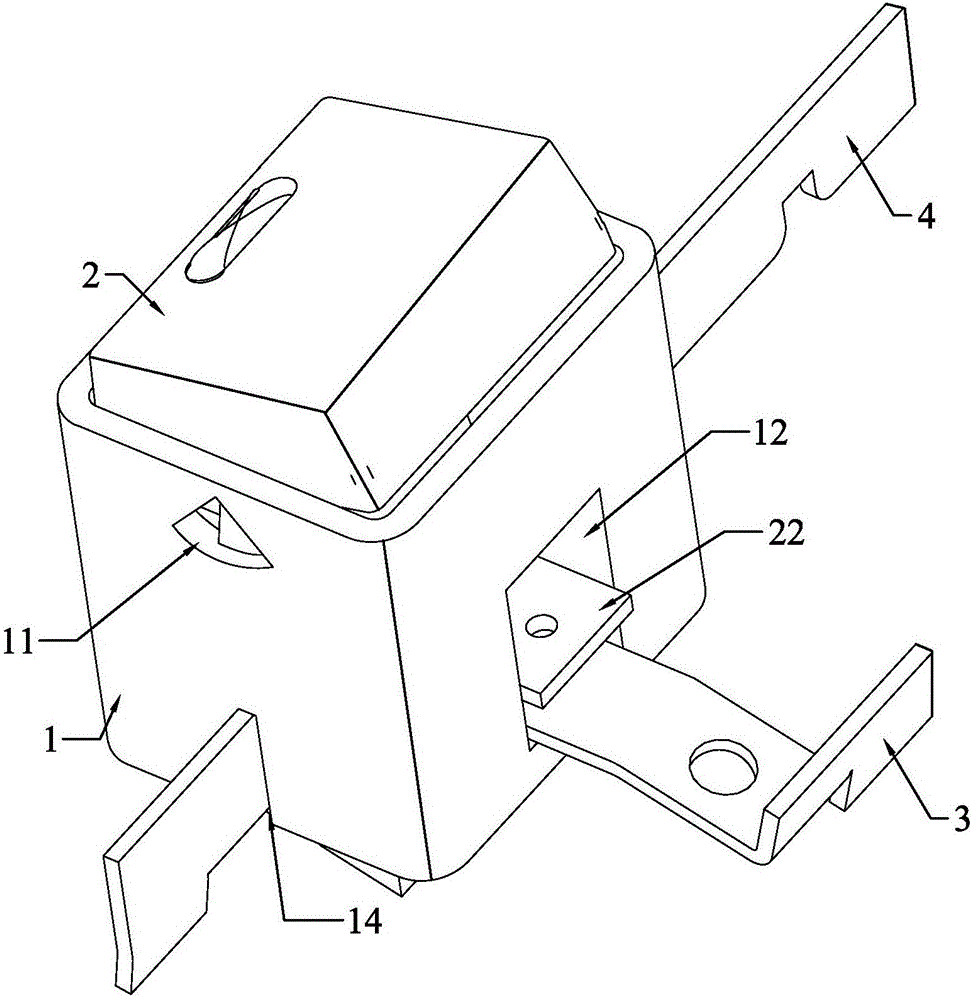

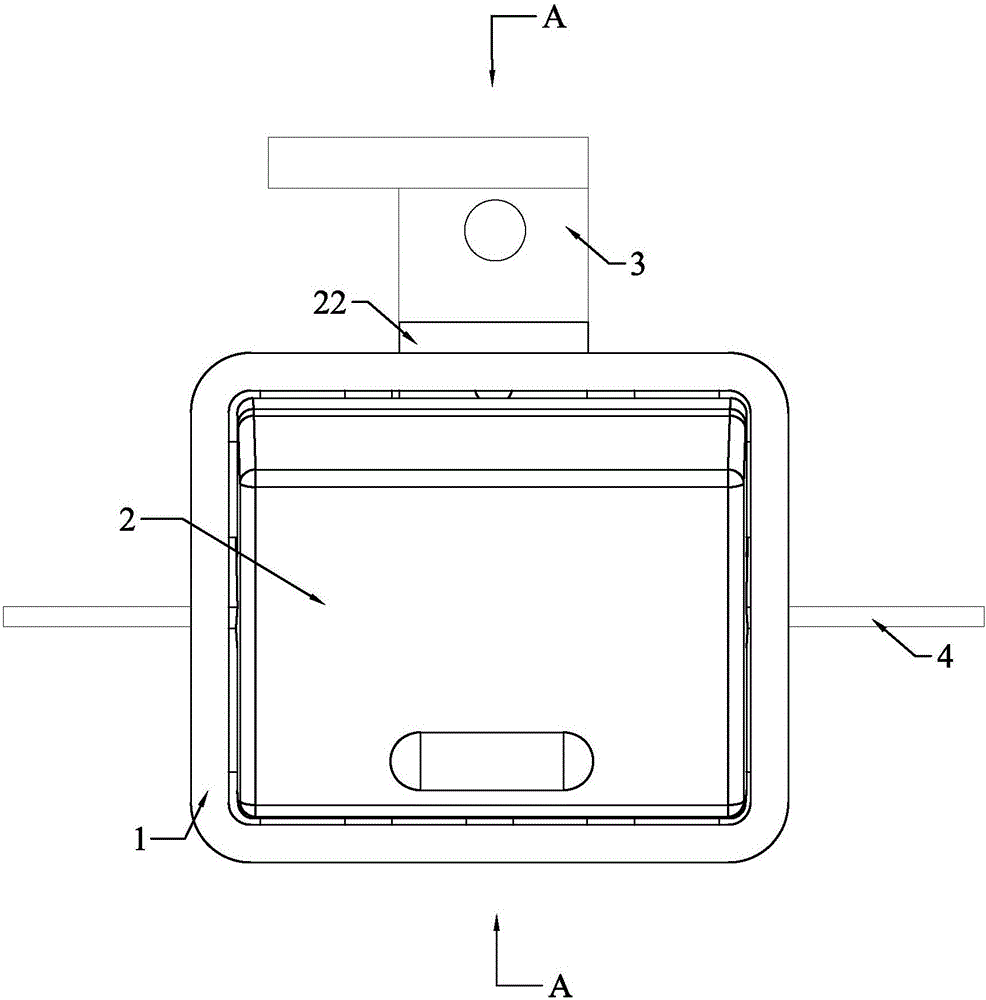

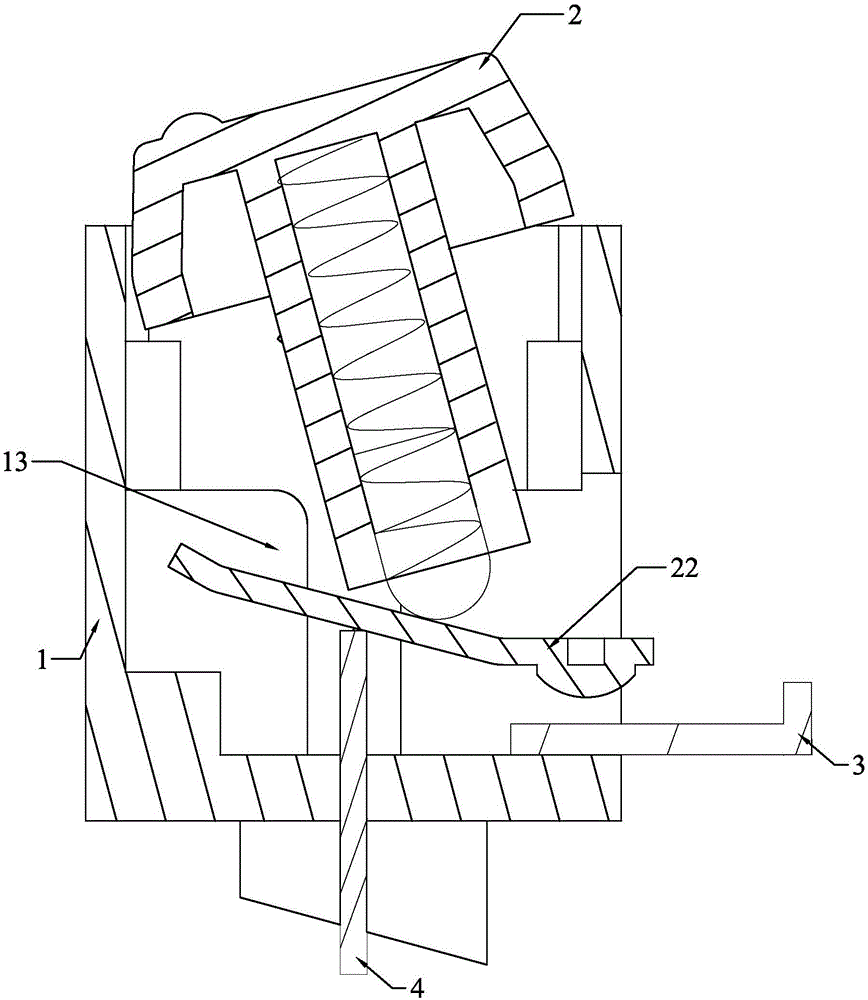

[0024] refer to Figure 1 to Figure 4 , the seesaw switch structure of this embodiment includes a housing 1, a seesaw button 2 and a seesaw contact piece 22, the seesaw contact piece 22 is installed in the housing 1, the seesaw button 2 is protruded from the housing 1, and the seesaw contact piece 22 is installed in the housing 1. The board button 2 is provided with a rotating boss 21, and the housing 1 is provided with a locking hole 11 with a limit structure 111, the rotating boss 21 is inserted into the locking hole 11, and the seesaw button 2 is thus flexibly connected with the housing 1 , press the seesaw button 2, the rotating boss 21 rotates and is fixed in the limit structure 111, refer to figure 1 with Figure 4 , the cross section of the limiting structure 111 in this embodiment is fan-shaped, and the cross-section of the rotating boss 21 is fan-shaped. 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com