Seal assembly, method for sealing a seal, bulk material container, docking device, and method for sealing a docking device

A technology of sealing components and docking devices, which is applied in the direction of unsealing of objects, containers, large containers, etc., can solve the problem of expansion and enlargement of sealing parts, and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

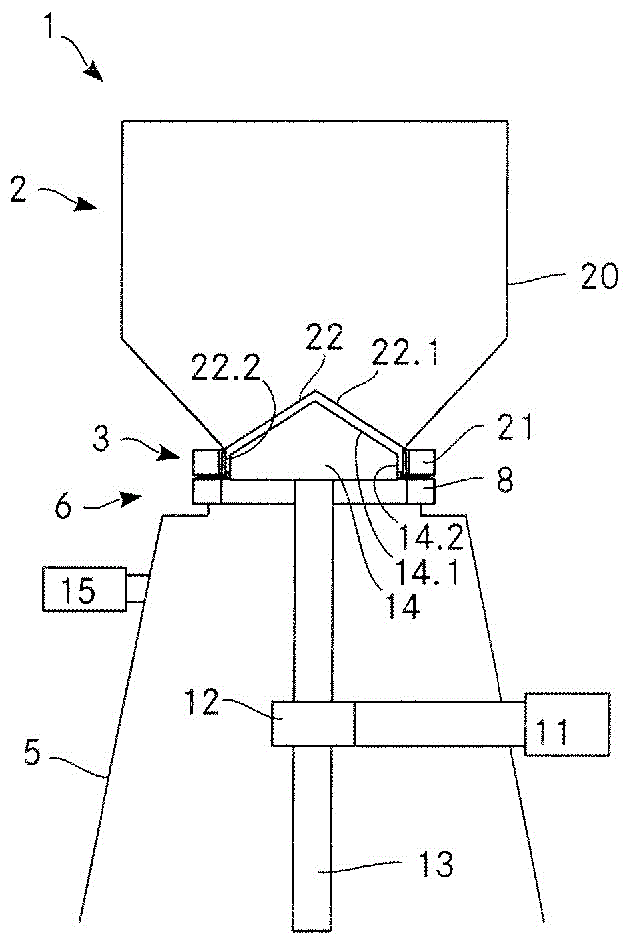

[0105] In principle, identical components are provided with the same reference symbols in the figures.

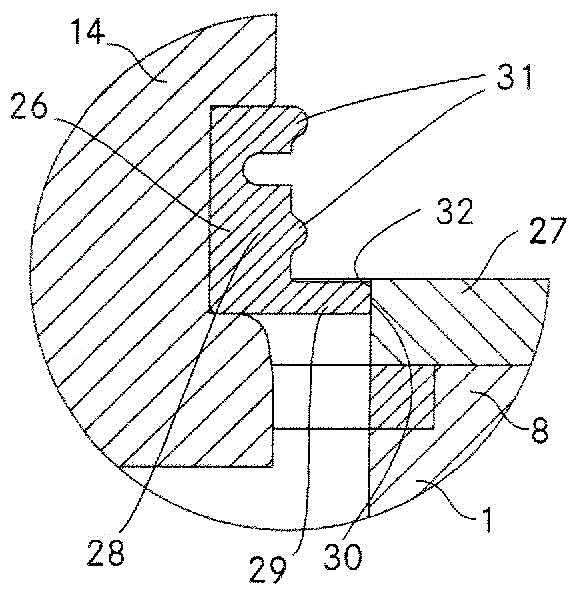

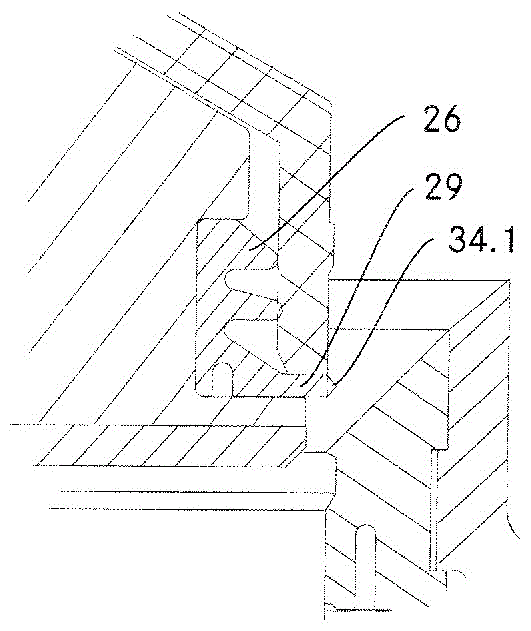

[0106] figure 1 and 2 A schematic illustration of a closure 3 according to the invention is shown in cross section. The closure 3 is in figure 1 in the slightly open position and in the figure 2 shown in the closed position. image 3 Again, an enlarged illustration with details of the contact area of the closing cone 22 and the coupling flange 21 is shown.

[0107] The closure element 3 in turn comprises a closure cone 22 which has a conical section 22.1 and a cylindrical section 22.2. Unlike the previous example, however, the coupling flange 21 comprises two flange elements: an inner flange element 21.1 and an outer flange element 21.2. The two flange elements are designed such that the inner flange element 21.1 can be fastened, for example welded, in the outer flange element 21.2 so that together they form a unit. For this purpose, the flange elements 21.1, 21.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com