Large turnover plow

A turning plow, large-scale technology, applied in the direction of plows, agricultural machinery and implements, applications, etc., can solve the problems of inconsistent cultivated land depth, uneven cultivated land, low efficiency, etc., achieve adjustable cultivated land depth, cultivated land leveling, and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

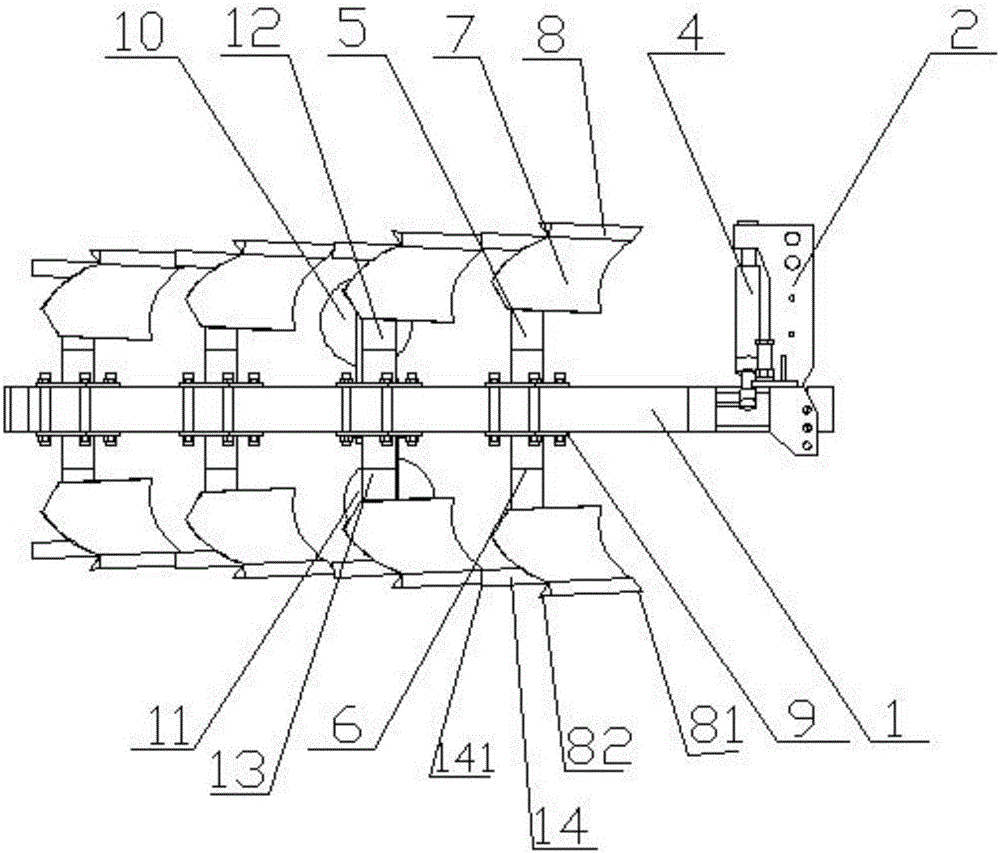

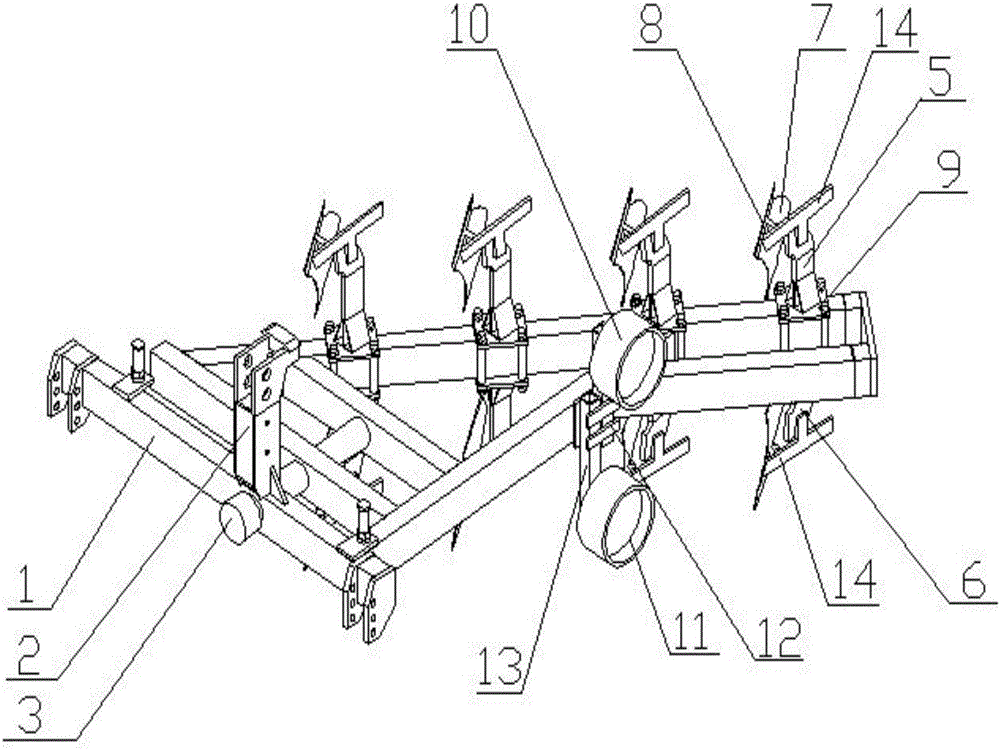

[0021] The large reversing plow includes a plow frame 1, a traction frame 2, a rotating shaft 3, a hydraulic cylinder 4, a plow column, a plow wall 7, a plow share 8, a connecting plate 9, a balance plate 14, traveling wheels, and a supporting frame for traveling wheels.

[0022] The traction frame 2 is fixedly mounted on the plow frame 1; the rotating shaft 3 is mounted on the plow frame 1 under the traction frame; one end of the hydraulic cylinder 4 is fixed on the plow frame 1, and the other end of the hydraulic cylinder 4 Fixed on the traction frame 1, the oil of the hydraulic cylinder 4 comes from the tractor, and the hydraulic power of the hydraulic cylinder 4 is controlled by the control valve in the cab of the tractor; the plow column is divided into an upper plow column 5 and a lower plow column 6, and the upper plow column The plow column 5 and the lower plow column 6 are fixedly mounted on the plow frame 1 symmetrically through the connecting plate 9, the described p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com