Automatic ditching device for vegetable greenhouses

A vegetable greenhouse, automatic technology, applied in the direction of excavation/covering trenches, applications, planting methods, etc., can solve the problems of impact management, uneven row spacing, uneven distribution of vegetable seeds, etc., to save labor and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

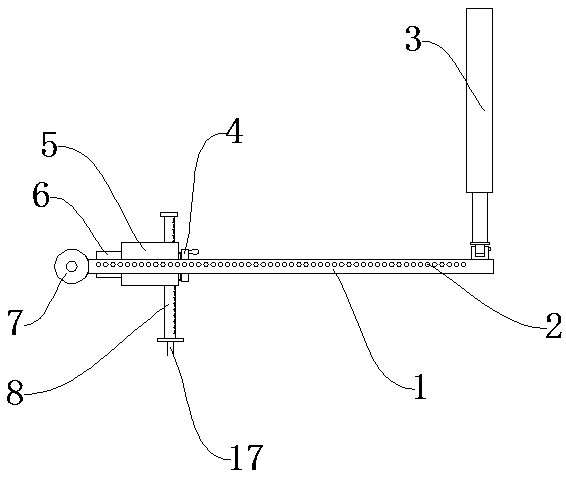

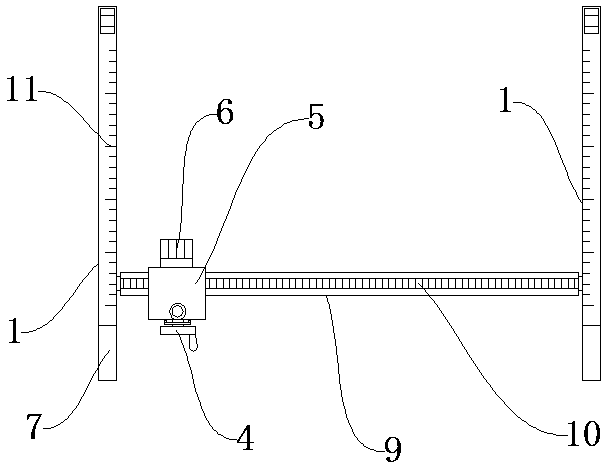

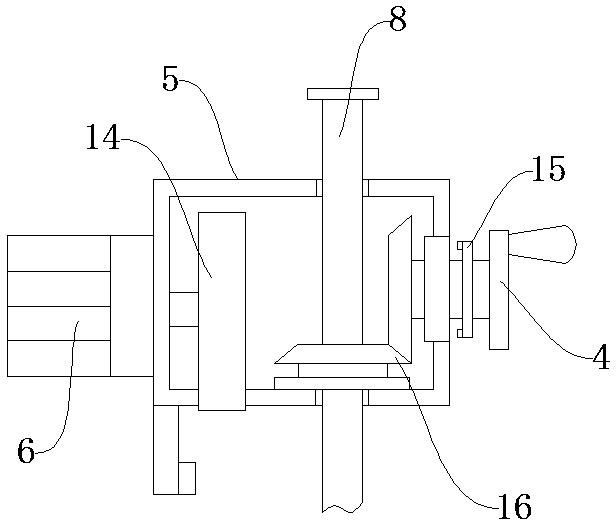

[0027] Such as Figure 1-Figure 4 As shown, an automatic ditching device for vegetable greenhouses comprises a transverse guide rail 1 and a longitudinal guide rail 9, one end of the transverse guide rail 1 is provided with a fixing ring 7, the fixing ring 7 is welded together with the transverse guide rail 1, and the other end of the transverse guide rail 1 is provided with a There are hydraulic adjustment rods 3, and limit holes 2 are processed at equal intervals on the side of the transverse guide rail 1, and limit pins 13 are arranged in the limit holes 2. A scale 11 is arranged on the upper surface of the transverse guide rail 1, and rollers 12 are arranged inside the transverse guide rail 1. The roller 12 is slidably connected inside the transverse guide rail 1, the side of the roller 12 is provided with a longitudinal guide rail 9, the upper surface of the longitudinal guide rail 9 is provided with a rack 10, the longitudinal guide rail 9 is provided with a moving seat 5...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is:

[0030] In this embodiment, the rack 10 is fixed on the longitudinal guide rail 9 by screws, the rack 10 meshes with the moving gear 14, and the moving gear 14 is fixed on the rotating shaft of the moving motor 6 through a key connection.

[0031] Specifically, such setting can drive the ditch opener 17 to carry out the ditching operation through the mobile motor 6, saving manpower.

[0032] The working principle of the present invention is: before use, control the hydraulic adjustment rod 3 to elongate to make the horizontal guide rail 1 rotate down to the horizontal direction, ensure that the horizontal guide rail 1 is parallel to the ground, adjust the position of the longitudinal guide rail 9 through the roller 12 and fix it with the limit pin 13 , then turn the depth adjustment handwheel 4 to make the opener 17 drop to the specified depth, use the locking plate 15 to lock the depth adjustment handwheel 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com