Self-propelled peanut gathering and picking machine

A self-propelled, peanut technology, applied in agricultural machinery and tools, threshing equipment, applications, etc., can solve the problems of easy pollution of the environment, large labor consumption, complex structure, etc., to ensure the quality of operation, high degree of automation, and contain impurities low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the goals to be achieved by the present invention, the technical solutions adopted, and the technical achievements obtained, the specific implementation methods of the present invention will be described in detail below in conjunction with the accompanying drawings.

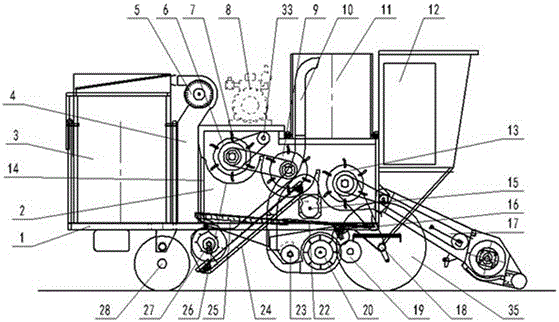

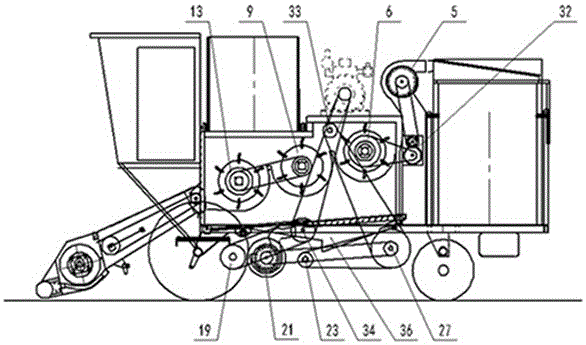

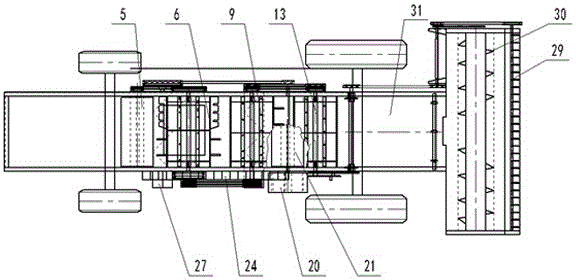

[0014] Such as figure 1 , figure 2 , image 3 As shown, the self-propelled peanut picking machine includes chassis 1, engine 8, running gear, picking device 17, fruit picking device, vibration separation and cleaning device, secondary cleaning device, fruit delivery device, and the output shaft of the engine Through the belt drive and the intermediate transmission shaft 33; the connected pick-up device 17 is installed on the front end of the fruit picking machine; the fruit picking device is composed of the first fruit removal drum 13, the second fruit removal drum 9, and the third fruit removal drum 6. The intermediate transmission shaft passes through Belt transmission is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap