Assembling jig for grating strip spring piece of printer

A technology of spring sheets and grating strips, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of poor assembly consistency of the grating strip spring sheets, easy deviation of the grating strip spring sheets, and inability to guarantee the grating strip spring sheets, etc. Achieve the effect of ensuring assembly consistency and improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

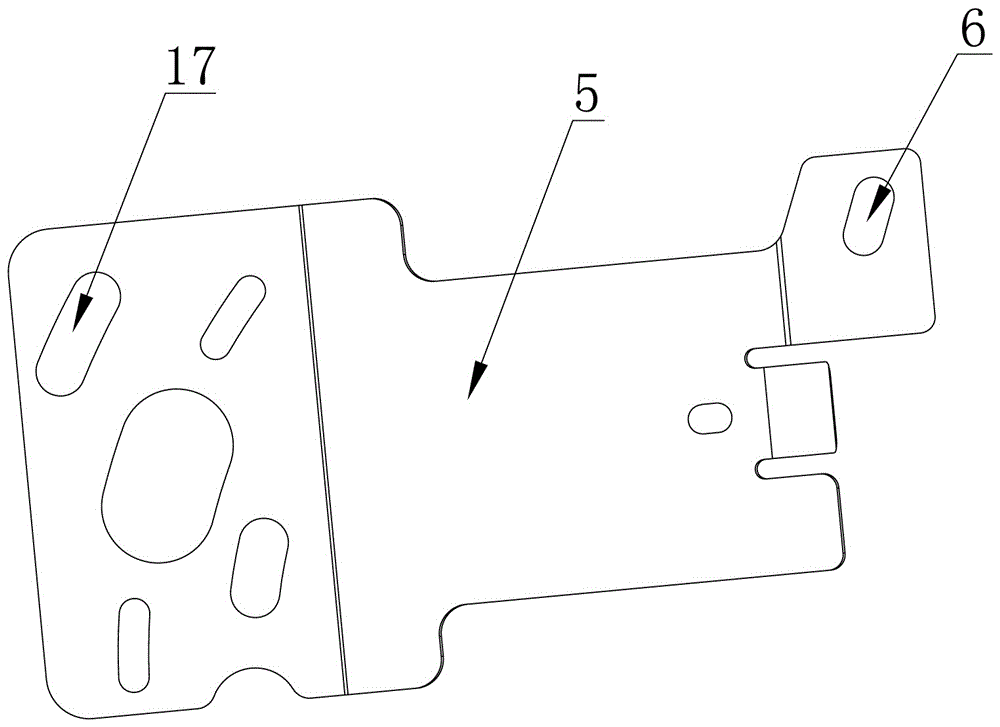

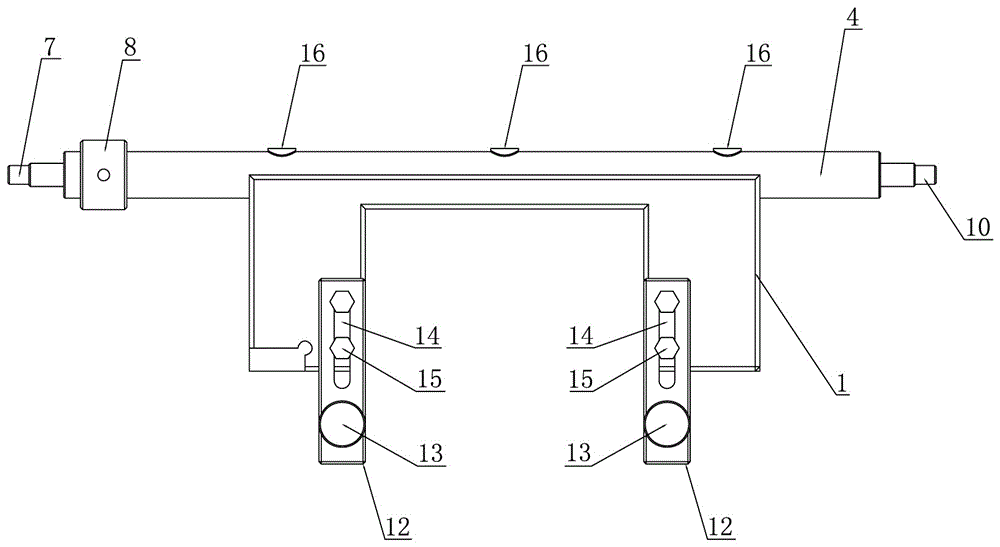

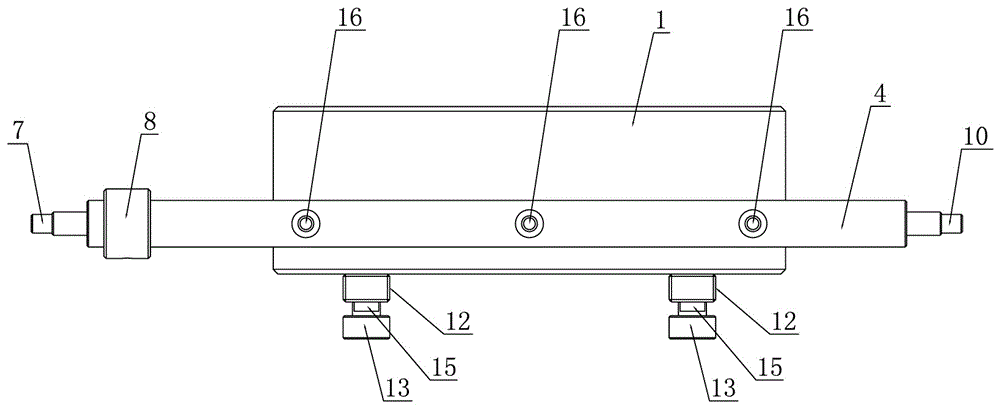

[0014] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the printer grating strip spring assembly jig includes a base 1, and a chute 3 that passes through the base 1 left and right and can be stuck on the print head movement shaft 2 is provided at the bottom of the base 1. 1 Translate axially along the moving shaft 2 of the print head through the chute 3, and the installation shaft 4 is arranged on the top of the base 1, and the positioning hole 6 on the grating bar spring piece 5 is set on the left end of the installation shaft 4. Rod 7 is provided with a limiter sleeve 8 at the end of the installation shaft 4 near the positioning rod 7, and the right end of the installation shaft 4 is provided with a limit insertion rod 10 that can be inserted into the jack on the left side of the inkjet print head 9. The base 1 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com